200L Vacuum Emulsifying Mixer

The 200L Vacuum Emulsifying Mixer from Yuanyang combines advanced technology with reliable performance to meet the demanding needs of cosmetic, pharmaceutical, and food production. As a key product from one of China’s leading industrial mixer manufacturers, this machine guarantees efficient, uniform mixing through vacuum emulsification, resulting in high-quality, stable emulsions.

Built to handle up to 200 liters per batch, this mixer operates under vacuum conditions to prevent air entrapment and oxidation, which ensures product purity and extends shelf life. The powerful homogenizing system enables thorough dispersion and emulsification of raw materials, providing a smooth and consistent mixture suitable for creams, lotions, sauces, and more.

Yuanyang has been a trusted name in the mixing equipment industry since 2008. Our vacuum emulsifying mixers are complemented by a full range of production line equipment, including storage tanks, filling machines, capping machines, and labeling systems. We provide comprehensive technical support, from free training to turnkey installation services, to ensure your operations run smoothly and efficiently.

Safety and compliance are our priorities. This model has earned multiple CE certifications, reflecting its adherence to strict safety and health standards demanded in global markets. With a user-friendly interface and robust construction, the 200L vacuum emulsifying mixer reduces downtime and maintenance efforts, making it an ideal investment for medium-sized production facilities.

Choose Yuanyang’s 200L Vacuum Emulsifying Mixer for a dependable, high-performance solution that boosts your production quality and capacity while providing peace of mind through professional support and certified safety standards.

Visit our website (https://www.yuanymachinery.com/) to learn more about our full product range and services.

Key Features:

- 200-liter capacity for medium-scale production

- Vacuum emulsification to prevent air inclusion and oxidation

- High shear mixing for thorough and uniform blend

- CE certified for international safety compliance

- Durable, easy-to-clean stainless steel construction

- Free technical training and turnkey installation support from Yuanyang

Trust Yuanyang for high-quality, efficient, and reliable industrial mixing solutions that meet your production needs and exceed expectations.

Detailed display

FAQ

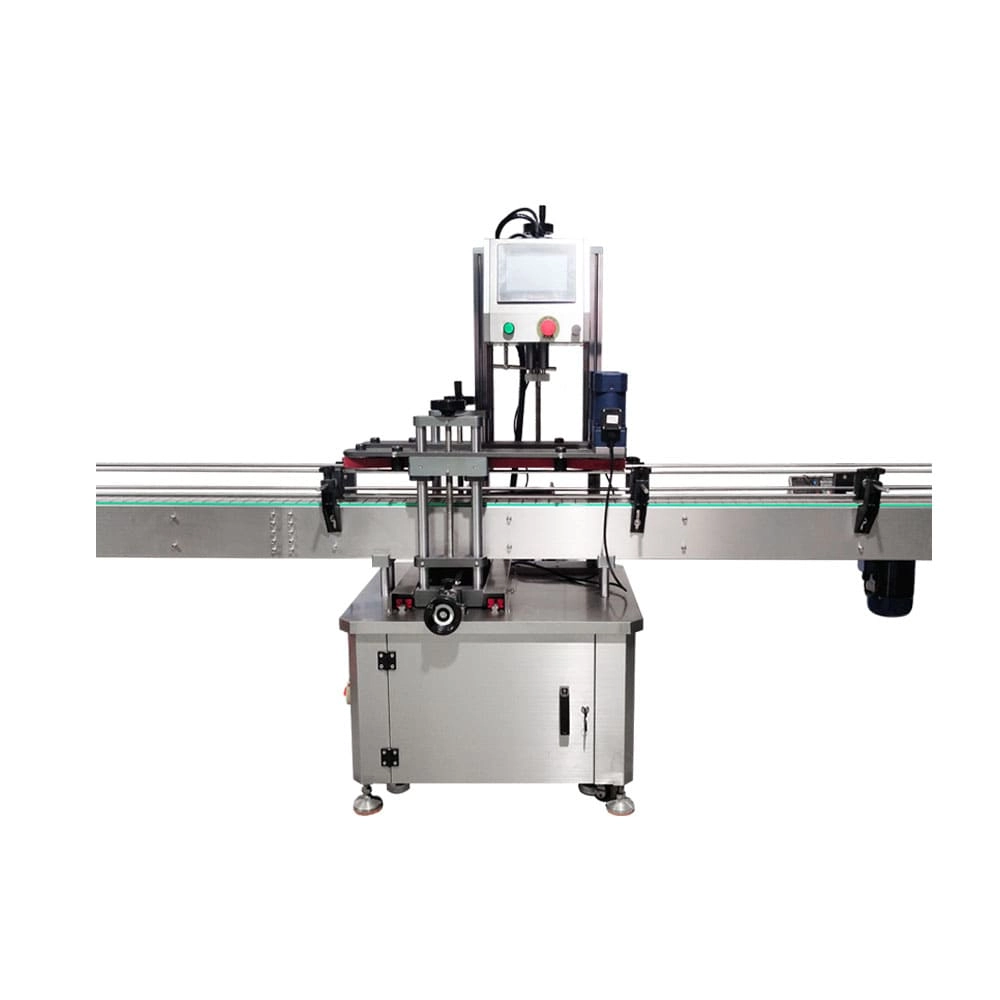

Can this capping machine for bottles be connected with filling machine,or labeling machine?

Yes, if client already has an old automatic labeling machine, just tell the conveyor height, we will customize our capping machine height.

Why water pot and oil pot are needed?

The combination of water pot and oil pot plays a crucial role for cosmetic production equipment, which ensure the stability of the emulsification process and product quality through pretreatment and precise control each phase materials.

⦁ Pretreatment

The water pot and oil are equipped with heating and dispersing function. Each phase can be dissolved,dispersed,heated before entering into the main emulsifying equipment. The pretreatment improves emulsification efficiency, reduces unnecessary mixing problems, and ensures that the material is in the best condition during emulsification

⦁ Precise control

Each phase is with a separated pot. Through the precise control system of water pot and oil pot, the materials can be added to the emulsion pot according to the preset ratio and speed, to ensure the uniformity and stability of the mixing process. This precise control helps to produce a high quality, consistent product.

What’s the pressure it requires?

This semi automatic filling machine is full pneumatic drive, need an air compressor. The working pressure is 0.4-0.6Mpa.

Can you explain the working principle of this air cooling sealing machine?

Working principle: the host sends the ultra-audio current to the sensor head, which is generated by electromagnetic induction in the head of the sensor The flow, to the instant high temperature, the aluminum foil composite film is melted and bonded to the bottle opening, to achieve the effective high quality sealing effect.

If you have any questions or concern, please contact us.

Automatic Screw Capping Machine for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

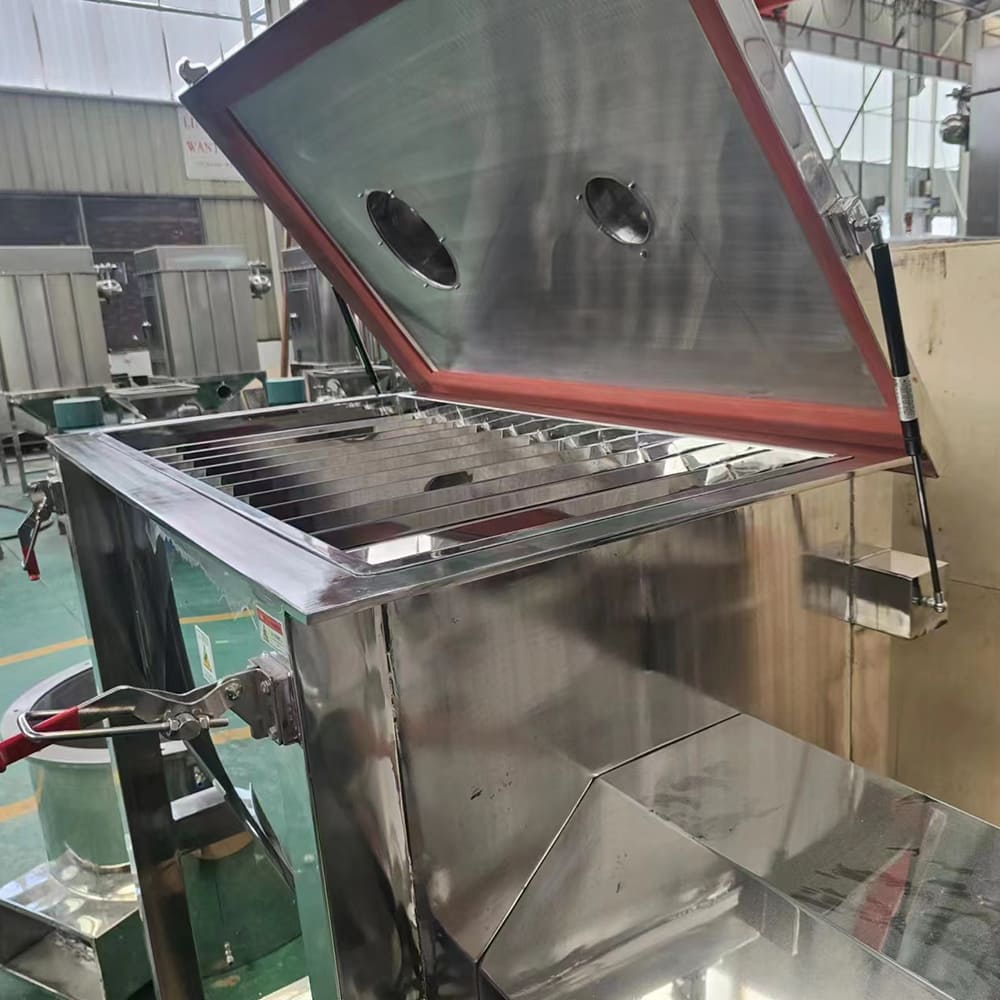

Homogenizer Mixing Tank with Circulation System for Sale

Yuanyang homogenizer mixing tank is a stainless steel homogenizer mixer tank. The homogeneous mixer machine is the core part for the liquid soap production line for shampoo, body wash, laundry detergent, dish soap, hand sanitizer, and other thick liquids.

Features:

⦁ Flat top half-open lid, electric control system.

⦁ Suitable for various liquid cleaning products and sauces.

⦁ PTFE wall scrapers stirring at top, high shear homogenizer at bottom.

Melting Tank for sale

The Yuanyang melting tank is a jacket tank with heater. The heating tank for liquid is made of food grade stainless steel materials, widely used for wax, butter, honey, chocolate, sugar, candle and so on.

Features:

⦁ Capacity from 50 to 5000 L.

⦁ Food grade materials.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery