Material Compatibility: Choosing the Right Tube Sealing Machine

- Material Compatibility: Choosing the Right Tube Sealing Machine

- Why material compatibility matters when selecting a sealing machine

- Overview of common tube materials and their properties

- Common sealing technologies for tubes (and where they fit)

- Compatibility matrix: selecting sealing machine by tube material and product

- Key material compatibility factors to evaluate

- How the Automatic Tube Sealing Machine for Sale addresses material compatibility

- Production considerations: throughput, changeover, and validation

- Maintenance and lifecycle costs tied to material compatibility

- Case scenarios: choosing the right configuration

- Selecting and testing a sealing machine: a practical checklist

- Comparative table: sealing methods vs. operational priorities

- Brand fit: Why consider the Yuanyang Automatic Tube Sealing Machine for Sale?

- FAQ — Material Compatibility and Tube Sealing Machines

- Contact / View Product

- Authoritative references and further reading

Material Compatibility: Choosing the Right Tube Sealing Machine

Why material compatibility matters when selecting a sealing machine

Choosing the correct sealing machine is more than picking equipment that closes a tube—it's about ensuring product integrity, regulatory compliance, production efficiency, and long-term reliability. The term sealing machine commonly refers to equipment that performs the final closure process for tubes, such as crimping, heat sealing, or induction sealing. If the sealing method does not suit the tube material (aluminum, laminate, or plastic), manufacturers risk leaks, contamination, failed quality checks, product recalls, and costly downtime. For regulated industries, always verify quality and compliance standards for sealing machines, guaranteeing that equipment meets safety, hygiene, and industry-specific certification requirements.

Overview of common tube materials and their properties

Understanding tube construction is the first step to pairing materials with the right sealing machine. Typical tube types are:

- Aluminum tubes: Rigid, high barrier to gases and moisture, suitable for creams, ointments, adhesives. They are compatible with mechanical crimping and induction sealing of inner liners.

- Plastic tubes (PE/PP): Flexible, low cost, chemically resistant depending on polymer grade, commonly heat-sealed or induction-sealed with compatible liners.

- Laminate (multi-layer) tubes: Combine metal foils and polymers to achieve desired barrier, flexibility, and printability. Sealing depends on the inner sealant layer—typically heat-sealable polymers.

Common sealing technologies for tubes (and where they fit)

Sealing technologies must be matched to the tube material and the packaged product:

- Crimping — mechanical closing often used for aluminum tubes; reliable for soft metals but not applicable to many plastics.

- Heat sealing — uses temperature and pressure to fuse thermoplastic layers; ideal for plastic and laminate tubes with compatible sealant inner layers.

- Induction sealing — electromagnetic heating of a foil liner to create a hermetic seal; excellent for liquid or sensitive products and works when a conductive liner is present.

- Ultrasonic sealing — high-frequency vibration used to weld thermoplastics; advantageous for thin films and precision sealing without excessive heat.

Compatibility matrix: selecting sealing machine by tube material and product

The following table summarizes typical compatibility between tube material, product type, and recommended sealing method. This helps narrow the choice of sealing machine early in the procurement process.

| Tube Material | Typical Products | Recommended Sealing Methods | Comments |

|---|---|---|---|

| Aluminum | Ointments, adhesives, solder pastes | Mechanical crimping, induction sealing (with liner) | Excellent barrier; crimping provides secure closure; induction used for inner liner seals |

| Plastic (PE/PP) | Toothpaste, gels, lotions, food pastes | Heat sealing, ultrasonic sealing, induction sealing (with liner) | Sealing depends on inner sealant layer; heat/ultrasonic are common |

| Laminate (multi-layer) | Cosmetics, pharmaceuticals, high-barrier foods | Heat sealing, induction sealing (when designed for), ultrasonic | Inner sealant determines method; lamination adds flexibility and barrier properties |

Key material compatibility factors to evaluate

When evaluating a sealing machine for sale, consider these technical factors that determine compatibility:

- Sealant layer chemistry — tube inner layers often include a specific heat-sealing polymer; ensure the machine’s heat profile and dwell time match that polymer.

- Thermal sensitivity of the product — some formulations degrade under heat; choose induction or ultrasonic sealing to minimize heat exposure to contents.

- Barrier requirements — oxygen- or moisture-sensitive products need high-barrier tubes and validated sealing (hermetic seal verification).

- Viscosity and product particulate — highly viscous or particulate-laden fills may require specific filling and sealing timelines to prevent contamination of the seal area.

- Regulatory and hygiene needs — medical, pharmaceutical, and food products have stricter validation and traceability requirements; sealing machines must support cleanability and GMP documentation.

- Tube diameter, length, and material thickness — the equipment must mechanically handle the range of tube sizes with adjustable jaws and fixtures.

How the Automatic Tube Sealing Machine for Sale addresses material compatibility

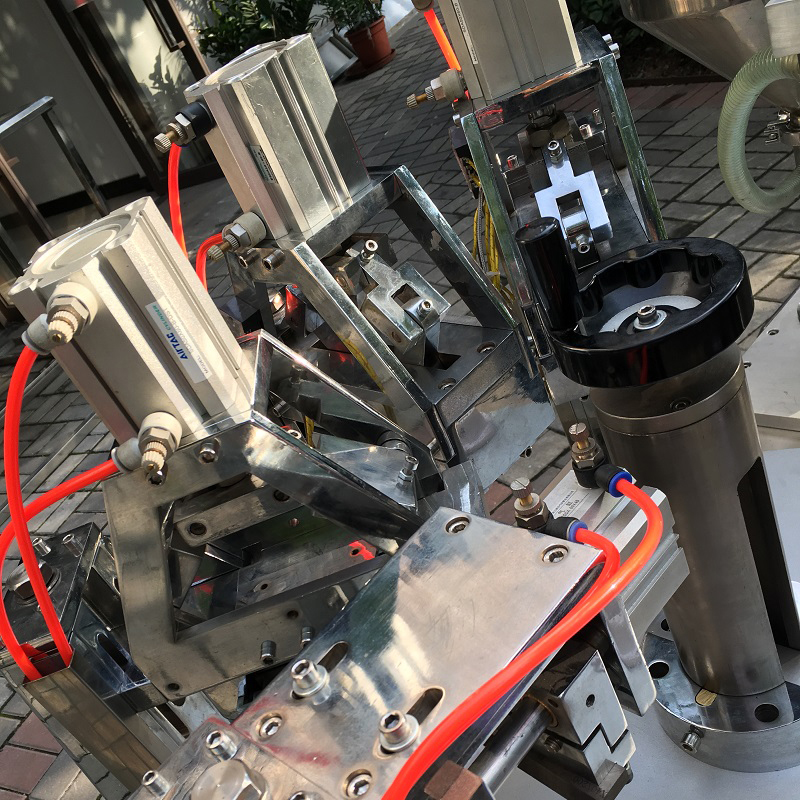

Yuanyang automatic tube sealing machine is an integrated automatic packaging machine with filling and sealing for aluminum or plastic tubes. The tube packing machine has become an indispensable piece of equipment in modern production for cosmetic, food, medicine, chemical, and other fields.

Features:

- Touchscreen operation, humanized design, simple and intuitive.

- Pneumatic filling control to ensure the accuracy of filling.

- Photoelectric sensing and pneumatic linkage control.

- Pneumatic control valve, efficient and safe. The runner can be adjusted and cleaned separately.

This integrated design simplifies material compatibility management in several ways:

- The touchscreen lets operators set sealing temperature, dwell time, and sealing pressure to match tube sealant chemistry quickly.

- Pneumatic controls ensure consistent pressure during heat sealing or crimping, which is critical for repeatable hermetic seals across varying tube wall thicknesses.

- Photoelectric sensing reduces misfeeds and misalignment, minimizing the risk of damaged seals that occur when tube position varies by material stiffness or elasticity.

Production considerations: throughput, changeover, and validation

When matching a sealing machine to tube materials consider operational constraints beyond basic compatibility:

- Throughput requirements — higher-speed sealing may demand precise temperature control and rapid response systems; plastic tubes may require faster cooling or different sealing cycles than metal tubes.

- Changeover flexibility — if you run multiple tube materials, choose machines with quick-change tooling, programmable recipes, and memory for saved parameters.

- Validation and quality control — machines should support in-line leak detection, torque testing for crimped closures, and data logging for regulated industries.

Maintenance and lifecycle costs tied to material compatibility

Material compatibility affects service intervals and consumables usage. For example, sealing polymer residue from certain formulations can build up on jaws and heating elements faster, requiring more frequent cleaning. Pneumatic runners and valves in the Automatic Tube Sealing Machine for Sale are designed to be adjusted and cleaned separately—this reduces downtime when switching between materials that leave different residues.

Case scenarios: choosing the right configuration

Below are three common scenarios and the recommended machine configuration:

- Cosmetic cream in laminate tubes — Recommend heat sealing with controlled temperature profiles and nitrogen purging if oxidation is a concern.

- Pharmaceutical ointment in aluminum tubes — Mechanical crimping combined with induction inner liner sealing; equipment should provide documented torque/crimp control and in-line seal integrity checks.

- Food paste in plastic tubes — Heat or ultrasonic sealing depending on sealant layer; choose a machine with sanitary design and easy runner cleaning for food safety.

Selecting and testing a sealing machine: a practical checklist

Use this checklist when evaluating options such as an Automatic Tube Sealing Machine for Sale:

- Confirm tube material types and inner sealant chemistry.

- Run production trials with real formulation and tube stock; measure seal strength and leak performance.

- Verify machine settings can be saved and recalled for different materials.

- Assess cleanability and maintenance access—remove runners, valves, and heating elements quickly.

- Check regulatory support: data logging, traceability, and validation documentation.

- Ensure spare parts availability for wear items tied to specific materials (jaws, liners, heating elements).

Comparative table: sealing methods vs. operational priorities

The table below offers a concise comparison of sealing methods against common production priorities.

| Sealing Method | Speed | Heat Exposure to Product | Suitability for Sensitive Products | Best Material Matches |

|---|---|---|---|---|

| Mechanical Crimping | Medium | Low | Good (no direct heat) | Aluminum tubes |

| Heat Sealing | High | Moderate to high | Depends on product thermal stability | Plastic, laminate |

| Induction Sealing | High | Minimal (localized to liner) | Excellent for sensitive liquids | Plastic, laminate with conductive liners |

| Ultrasonic Sealing | Medium to high | Low (mechanical vibration) | Good for thin films | Thermoplastic tubes |

Brand fit: Why consider the Yuanyang Automatic Tube Sealing Machine for Sale?

For manufacturers looking to match sealing technology to varied tube materials, Yuanyang’s integrated machine offers several advantages:

- Integrated filling and sealing minimizes handoffs and contamination risk—important when changing materials or formulations.

- User-friendly touchscreen and programmable controls reduce operator error during material changeovers.

- Pneumatic accuracy in filling helps protect seals from product splashback or overfill that can compromise seal quality.

- Photoelectric sensing ensures precise tube positioning regardless of material flexibility.

These features together make the machine a versatile option for cosmetic, food, medicine, and chemical manufacturers who handle aluminum or plastic tubes and need reliable, repeatable sealing performance.

FAQ — Material Compatibility and Tube Sealing Machines

- Q: Can one sealing machine handle both aluminum and plastic tubes?

A: Yes—many integrated machines, such as the Automatic Tube Sealing Machine for Sale, support both types, but ensure the machine has programmable sealing parameters and interchangeable tooling for crimping vs. heat/induction sealing.

- Q: How do I validate seal integrity for sensitive products?

A: Use dye ingress, vacuum leak testing, burst testing, or specific in-line seal detection systems. Maintain validation records and run periodic revalidation after maintenance or material changes.

- Q: What if my product contains abrasive or sticky ingredients?

A: Choose equipment with easy-to-clean runners and replaceable wear parts. Pneumatic valves and dosing components that can be cleaned or sterilized reduce downtime and contamination risk.

- Q: Is induction sealing suitable for food products?

A: Yes—if the tube design includes a conductive foil liner compatible with food contact regulations. Induction sealing provides strong, tamper-evident seals without heating the product bulk.

- Q: What tests should I run during material changeover trials?

A: Run mechanical seal strength, leakage, visual inspection for seal continuity, and accelerated shelf-life tests if possible. Document all parameters used for reproducibility.

Contact / View Product

If you need help selecting the right sealing machine or want a production trial, contact our sales and technical team to discuss your tube materials, formulations, and throughput requirements. View the Automatic Tube Sealing Machine for Sale and request a quote or on-site demonstration to validate material compatibility under your real-world conditions.

Authoritative references and further reading

For technical and regulatory background on packaging materials and sealing methods, see:

- Tube (container) — Wikipedia: https://en.wikipedia.org/wiki/Tube_(container)

- Flexible packaging — Wikipedia: https://en.wikipedia.org/wiki/Flexible_packaging

- Induction sealing — Wikipedia: https://en.wikipedia.org/wiki/Induction_sealing

- FDA — Food Packaging & Food Contact Substances: https://www.fda.gov/food/packaging-food-contact-substances-fcs

- ISO 15378 — Primary packaging materials for medicinal products (overview): https://www.iso.org/standard/71654.

The latest trends for dry powder mixer blender | YUANYANG Ultimate Insights

Tips for buy industrial dry powder mixer

The latest trends for trigger spray capping machine

Tips for buy pharmaceutical powder mixer

Automatic auger filling machine

Is conveyor equipped together with the filling machine for powder?

Yes, the automatic powder filler machine is equipped with conveyor, which can be connected with other machines such as bottle sorting tables, capping machine, labeling machine and so on.

Homogneizer mixer tank

How long does the liquid soap mixer take to produce a batch?

It usually takes 0.5-1 hours or longer based quality requirement and formula.

Ink Jet Printer

Can the dater printer spray all directions?

Yes, the spraying nozzle of the expiry date printer can be adjusted to all directions.

Automatic Round Bottle Labeling Machine

Can you add a date printer for the labeling machine?

Yes, a coding machine for date printing can be added with labeling machine. It can print date on labels with ink. But for more functions,such print code, pictures, bar code, it is suggested to buy a separated ink jet printer.

Liquid Soap Mixer Machine

When shall we choose electric heating or steam heating?

The electric heating is with bottom electric tubes, the cost is lower compared with steam heating, which requires a steam generator and needs steam pipes. So we recommend small business choose electric heating for small capacity.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery