Vacuum Grease Emulsifying Mixer - Premier Industrial Mixing Solutions by YUANYANG

Vacuum Grease Emulsifying Mixer: Advanced Mixing Solutions by YUANYANG

High-Performance Vacuum Grease Emulsifying Mixer Technology

YUANYANG specializes in advanced vacuum grease emulsifying mixers designed to deliver superior emulsification and homogenization results. Our mixers utilize cutting-edge vacuum technology that removes air bubbles during mixing, ensuring consistent product quality and stability, particularly in grease and viscous material applications.

Comprehensive Product Line and Turnkey Support

Since 2008, YUANYANG has committed to providing a full suite of industrial mixing equipment, including vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers. Beyond individual machines, we offer integrated production line solutions including storage tanks, filling, capping, labeling, and sealing machines — all fully supported by our free technical training and one-stop installation services.

Certified Quality and Global Industry Recognition

YUANYANG’s vacuum grease emulsifying mixers carry multiple CE certifications, underscoring compliance with European safety and health standards. While CE certification is not a direct quality mark, it assures customers of our commitment to product safety and reliability, making our mixers a trusted choice for industrial manufacturers worldwide.

Why Choose YUANYANG for Your Mixing Needs?

As one of China’s leading industrial mixer manufacturers, YUANYANG focuses on technological innovation and client satisfaction. Our vacuum grease emulsifying mixers feature robust designs, ease of operation, and exceptional emulsifying efficiency, perfectly suited for grease manufacturing, cosmetics, pharmaceuticals, and chemical industries. Partner with YUANYANG to elevate your production line with professional, proven mixing solutions.

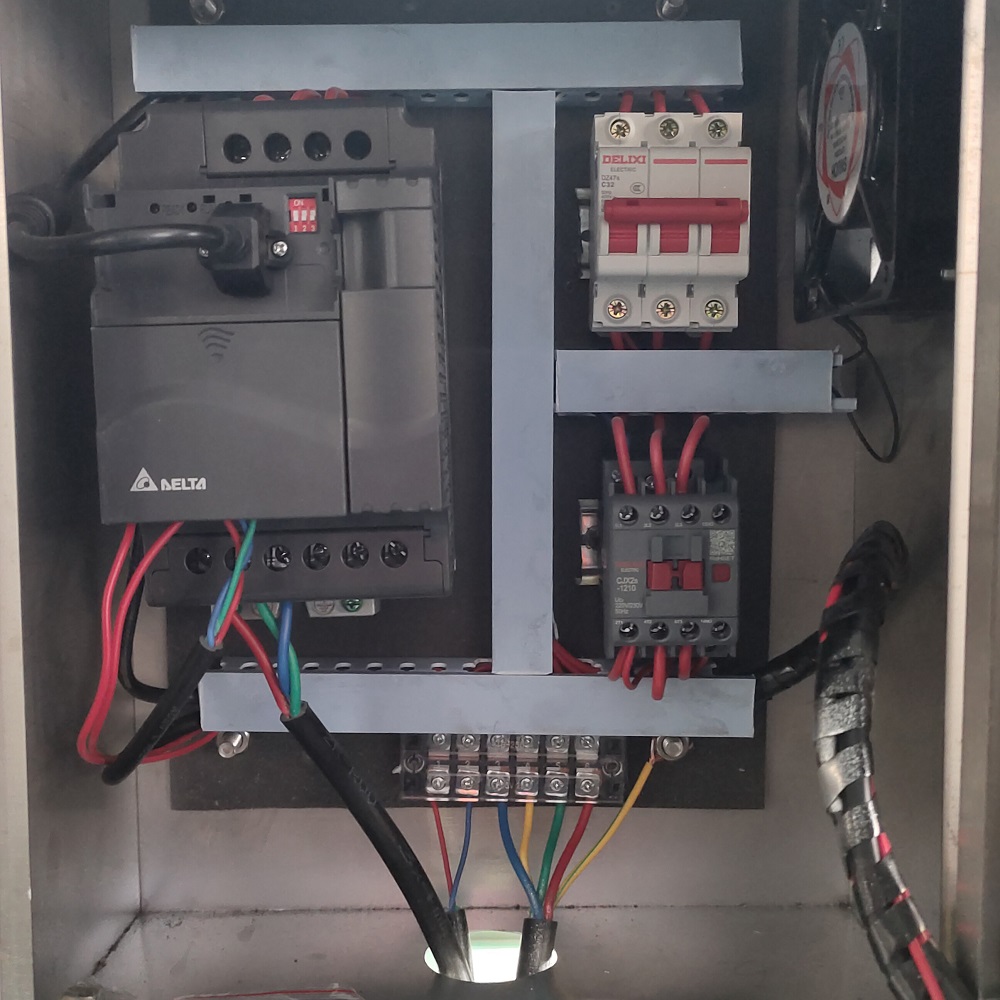

vacuum grease emulsifying mixer Display

Can I change the different paddle by myself?

Generally the paddle can not be replaceable, unless the new paddle to be changed are the same size with the old one.

How to dry the mixed powder?

If the raw powder is not dry, and client wants to dry it during mixing, a jacket will be added with heater to achieve drying purpose.

How long does the liquid soap mixer take to produce a batch?

It usually takes 0.5-1 hours or longer based quality requirement and formula.

The power supply is 220v 60hz, can I use this paste filling machine?

Sure, the machine is only pneumatic drive, you just use local air compress to connect to it. There is no need to worry about power supply.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery