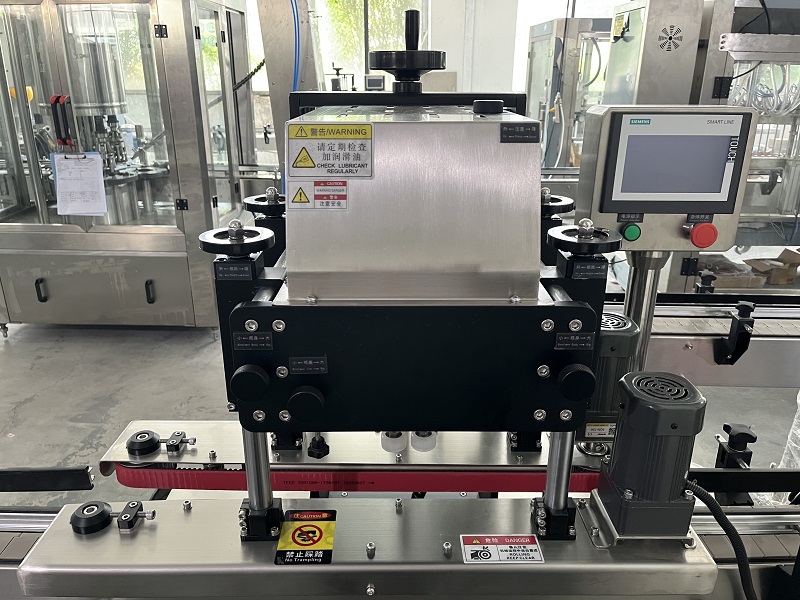

YUANYANG Automatic Bottle Capping Machine

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

YUANYANG Automatic Bottle Capping Machine – Precision & Efficiency for Seamless Production

Upgrade your production line with YUANYANG’s automatic bottle capping machine, designed for unmatched speed, accuracy, and reliability. As a leading China-based industrial equipment manufacturer since 2008, we specialize in high-performance capping solutions that streamline your workflow while ensuring consistent quality.

Why Choose YUANYANG?

✔ CE-Certified – Meets EU safety standards for worry-free operation.

✔ One-Stop Support – Free technical training and turnkey installation services.

✔ Versatile Compatibility – Works seamlessly with various bottle sizes and cap types.

✔ Durable & Low-Maintenance – Built for long-term efficiency in demanding environments.

Perfect for:

- Food & beverage, pharmaceutical, and cosmetic industries.

- High-speed production lines requiring precision capping.

Trust YUANYANG to deliver industrial-grade reliability with our automatic capping machine—enhancing productivity while reducing labor costs. Contact us today for a tailored solution!

*Keywords: automatic bottle capping machine, YUANYANG, CE-certified, industrial capping solution*

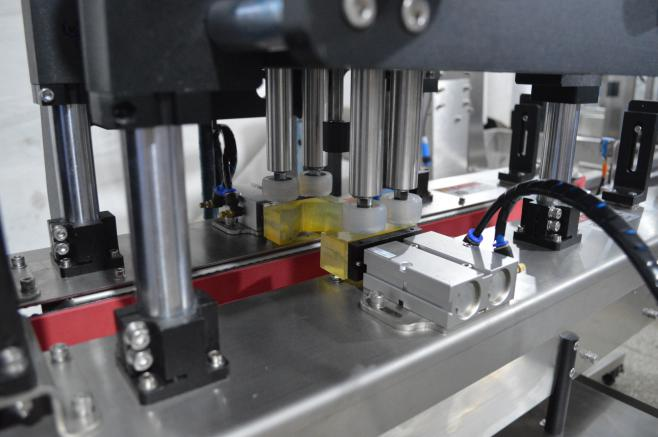

Detailed display

Q&A

What’s frequency converter (VFD) used for this cosmetic emulsifier?

We have 2 brand of converter for clients to choose. The standard converter is Delta, the optional choice is Mitsubishi.

What materials does this plastic bag packing machine can pack?

This packing machinery can pack liquids, cream, paste, sauce, shampoo and similar materials.

Why water pot and oil pot are needed?

The combination of water pot and oil pot plays a crucial role for cosmetic production equipment, which ensure the stability of the emulsification process and product quality through pretreatment and precise control each phase materials.

⦁ Pretreatment

The water pot and oil are equipped with heating and dispersing function. Each phase can be dissolved,dispersed,heated before entering into the main emulsifying equipment. The pretreatment improves emulsification efficiency, reduces unnecessary mixing problems, and ensures that the material is in the best condition during emulsification

⦁ Precise control

Each phase is with a separated pot. Through the precise control system of water pot and oil pot, the materials can be added to the emulsion pot according to the preset ratio and speed, to ensure the uniformity and stability of the mixing process. This precise control helps to produce a high quality, consistent product.

I don’t need homogenizer, can you reduce it?

Yes, the homogenizer is an optional function, whether clients need it depends on your own products.

If you don’t find your answer, please E-mail us and we’ll be happy to help you out.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery