YUANYANG Vacuum Emulsifying Homogenizer Mixer - Leading Industrial Mixing Solutions

YUANYANG Vacuum Emulsifying Homogenizer Mixer: Excellence in Industrial Mixing

Leading Manufacturer with Proven Expertise

Since 2008, YUANYANG has been at the forefront of industrial mixer manufacturing in China, specializing in vacuum homogenizers, vacuum emulsifying mixers, and other advanced vacuum mixers. Our products combine innovative technology and robust design to ensure consistent, high-quality mixing performance across various industries.

Advanced Vacuum Emulsifying Homogenizer Mixer Technology

The vacuum emulsifying homogenizer mixer integrates vacuum technology with high-shear emulsification and homogenization, enabling efficient dispersion, emulsification, and mixing of complex formulations. This ensures improved product stability, texture, and uniformity, making it ideal for cosmetics, pharmaceuticals, food, and chemical industries.

Comprehensive Turnkey Solutions and Support

YUANYANG offers not only state-of-the-art mixing equipment but also complete production line solutions, including storage tanks, filling machines, capping machines, labeling machines, and water treatment equipment. Our commitment extends to free technical training and one-stop installation services, providing seamless integration and reliable after-sales support.

Certified Quality and Global Vision

With multiple CE certifications, YUANYANG guarantees safety and compliance for markets worldwide, particularly within the EU. Our mission is to become the premier global manufacturer of industrial mixers and agitators, combining quality, innovation, and customer-centric service.

Why Choose YUANYANG Vacuum Emulsifying Homogenizer Mixer?

- Efficient vacuum and high-shear mixing technology

- Robust, durable construction for long-term use

- Comprehensive turnkey production line solutions

- Free technical training and expert installation support

- Multiple CE certifications ensuring safety and compliance

Explore YUANYANG's vacuum emulsifying homogenizer mixers to elevate your production capabilities and achieve superior mixing results. Visit www.yuanymachinery.com for more information.

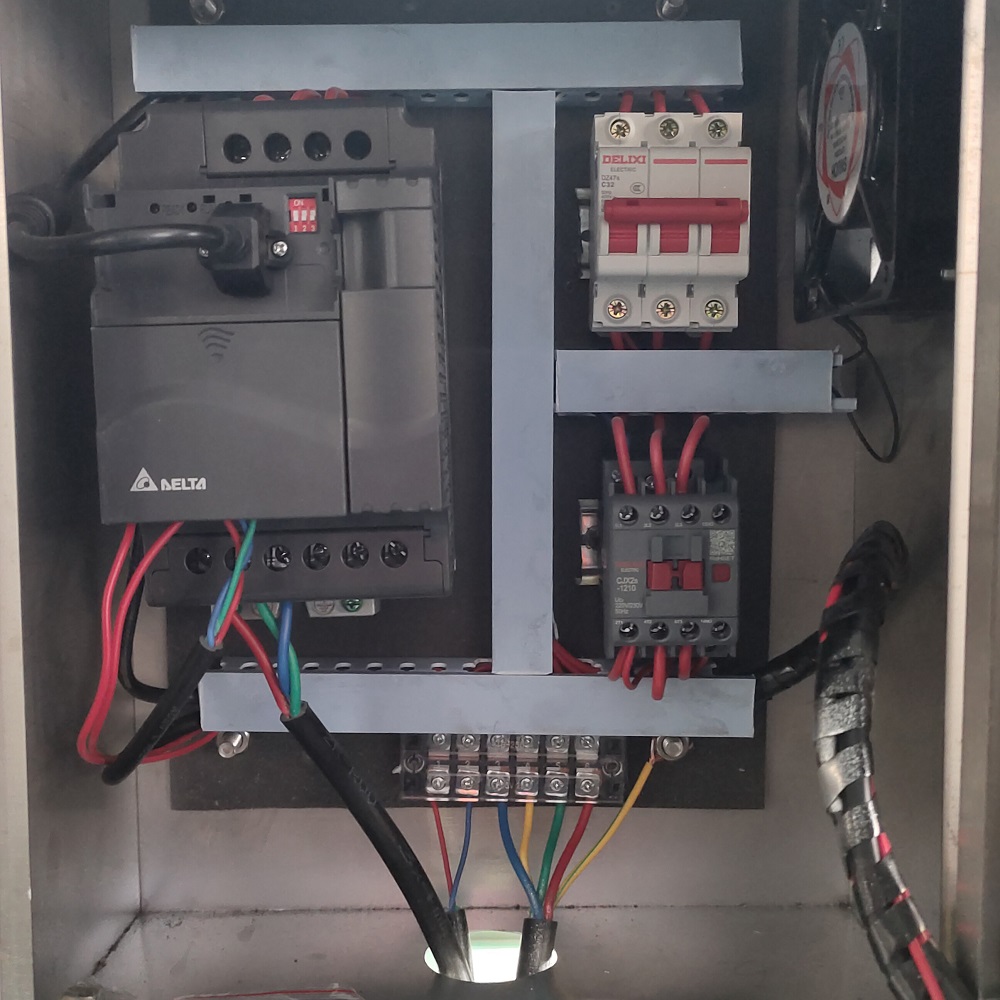

vacuum emulsifying homogenizer mixer Display

Is the material of the cosmetic tank anti-corrosive?

Yes, the tank is made of stainless steel 304 or 316L, it can store corrosive chemicals. But it is recommend to use PP storage tank if the liquid is strong acid, alkali and corrosive chemical liquid

Do you have different diameter for the vibrating sieve machine?

Yes, we will recommend the suitable type according to capacity.

How to clean the inside tank?

There will be installed with rotary ball and valves on the lid, client uses high pressure water to clean or a high pressure gun to wash. Load tap water into tank, add some cleaning liquids, operate heating function and mixing function for better cleaning.

What’s the cooling method of the bottle lid sealing machine?

This bottle lid sealer adopts air cooling method.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery