YUANYANG – Leading Inline Homogenizer Manufacturers

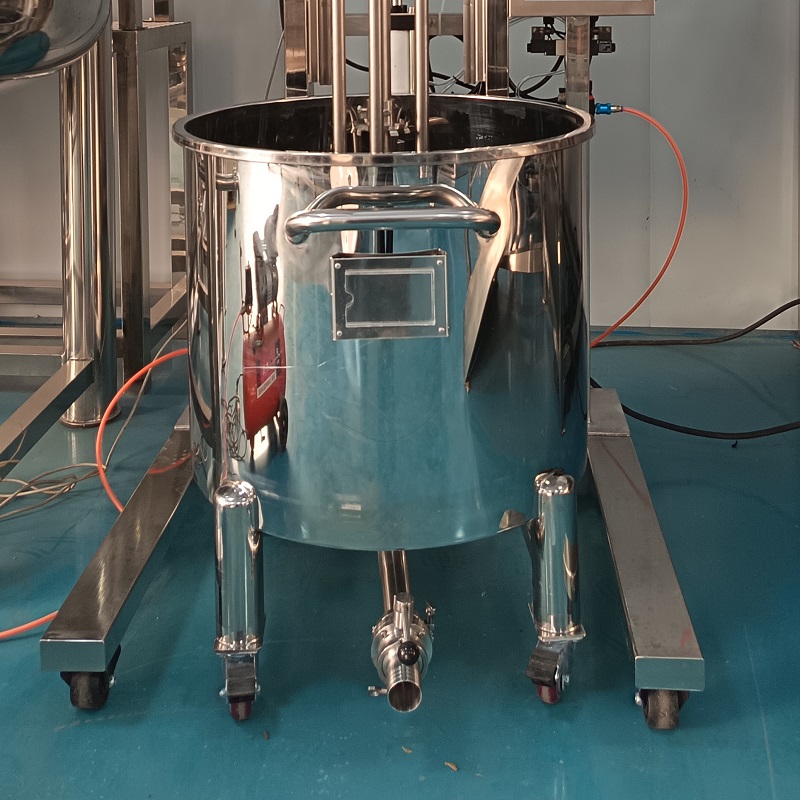

Yuanyang pneumatic lifting homogenizer with bucket is a multifunctional automatic lifting high shear mixer, widely used for emulsifying, dispersing and homogenizing cosmetic raw materials, chemical liquids washing production,food processing and pharmaceutical ingredients.

Features:

⦁ Working head can lift up and go down automatically;

⦁ Speed variable with frequency converter;

⦁ Electric button control;

⦁ Popular capacity: 50-500L

High Quality Inline Homogenizers by YUANYANG – Precision Mixing Solutions

YUANYANG is a leading inline homogenizer manufacturer in China, delivering high-performance mixing equipment since 2008. Our inline homogenizers are engineered for efficiency, durability, and seamless integration into industrial production lines.

Why Choose YUANYANG?

✔ CE-Certified – Compliant with EU safety standards for reliable performance.

✔ Turnkey Solutions – From mixing to filling, we provide complete production line support.

✔ Expert Technical Training – Free installation guidance and operational training.

✔ Versatile Applications – Ideal for pharmaceuticals, cosmetics, food, and chemicals.

Our product range includes vacuum homogenizer mixers, high shear mixers, and emulsifying systems, ensuring uniform blending for diverse industries. With YUANYANG, you gain a trusted partner committed to quality, innovation, and customer care.

Upgrade your production with YUANYANG’s inline homogenizers – where precision meets reliability. Contact us today for tailored solutions!

Product Images

Frequently Asked Questions

How to cool down fast? When the products is finished,the temperature is high, it takes a long time to get back to room temperature!

⦁The fast way is by using an external chiller to convey the cooling medium (usually cold water) through the pipe into the inner jacket,through water-circulation system to cool;

⦁Another way is directly continuously taking cooling medium (usually tap water) into the inner jacket of the agitator tank from inlet, and drain it from outlet to take away the heat.

How do you ensure consistent product quality during production?

Our equipment features precision control systems that ensure stability and consistency at every stage of production. Automation reduces human error, guaranteeing consistent quality across each batch.

What’s the material of the liquid tank?

The tank is made of stainless steel 304 or 316L. We customize upon requirements. Or we recommend according to clients’ products.

How to add liquids into the hopper of the fully automatic bottle filling machines?

The automatic liquid filling machine requires a pump to transfer liquids into hopper, and it can stop automatically with a liquid sensor inserted inside the hopper.

If you have another questions, please feel free to contact us.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery