Reverse Osmosis Water Treatment Systems

Reverse Osmosis Water Treatment Solutions by YUANYANG

Elevate Water Quality with Advanced RO Technology

YUANYANG’s reverse osmosis water treatment systems deliver consistently pure water essential for industrial production lines. By leveraging advanced RO membrane technology, our systems efficiently remove dissolved solids, contaminants, and impurities. The result? Clean, reliable water ideal for mixing, processing, and cleaning in manufacturing environments.

Tailored for Industrial and Turnkey Applications

We engineer our reverse osmosis water treatment solutions to integrate seamlessly into your production process. Whether you require RO systems for food processing, cosmetics manufacturing, or pharmaceutical production, YUANYANG offers solutions designed to meet strict quality standards. Our equipment is CE certified for safety and regulatory compliance in international markets.

Reliable, Low-Maintenance, and Cost-Efficient

Choose YUANYANG for robust, user-friendly reverse osmosis water treatment systems that are easy to operate and maintain. Efficient water purification helps reduce downtime, minimize energy consumption, and lower operational costs. We provide one-stop technical training and turnkey installation support, ensuring hassle-free setup and operation.

Complete Production Line Support

As specialists in industrial mixers, blenders, and automation equipment since 2008, YUANYANG also offers reputable water treatment solutions to complement our mixing and filling machinery. Count on us as your complete, single-source supplier for integrated production lines—from water treatment to finished product packaging.

Optimize your operations with YUANYANG’s reliable reverse osmosis water treatment systems. Trust in proven performance, CE certification, and full-service support from one of China’s industry leaders. Request a quote or consultation today.

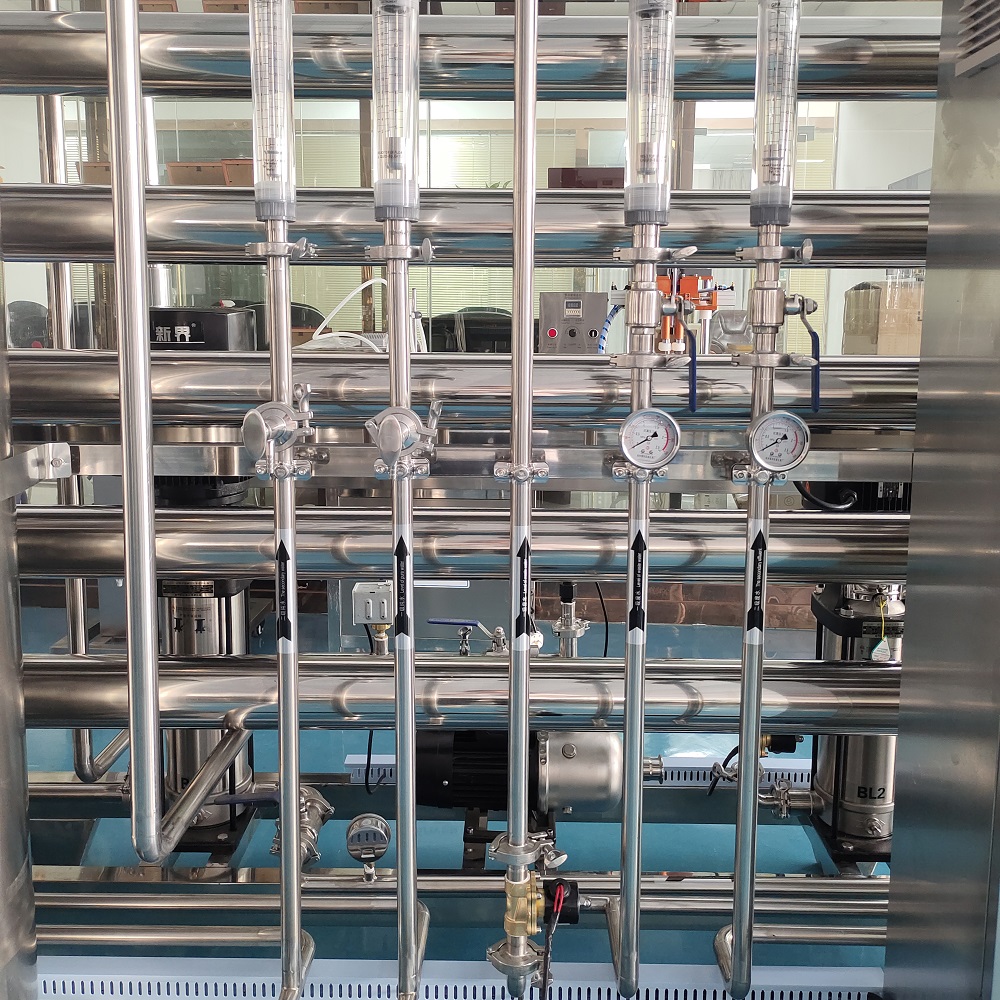

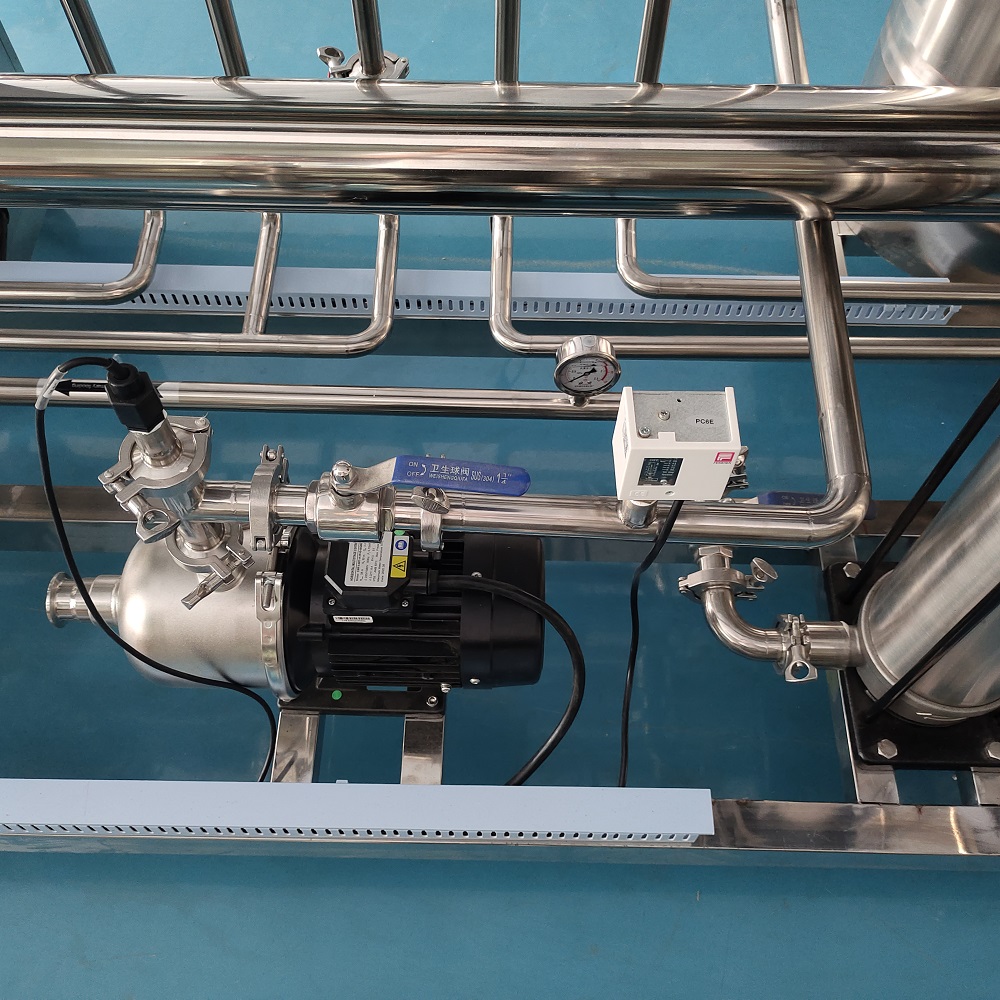

reverse osmosis water treatment Display

What’s the rotation speed of the bottom homogenizer head of the liquid detergent mixer?

The standard homogenizer is with high speed 3000 rpm, we can customize other bigger speed according to actual needs.

Can you directly send to my address?

Sure, we can arrange DDU or DDP shipment service, directly deliver the packages to client’s door.

Can you send me a drawing of the industrial mixer tank with homogenizer?

Yes, we have professional designers to draw according to customized requirements, including the dimensions, parts, structures, wire drawing and so on.

What raw materials can the equipment process?

Our equipment can process liquids, powders, solids, pastes, viscous materials, and high-viscosity substances, meeting a wide range of food production needs.

Can I add a top disco plate mixing paddle? My products need it.

Yes, we can add top disperser/homogenizer/frame mixing/scrapers mixing paddle. Yuany provide flexible and practical solutions for clients.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery