Reducing TCO: Energy and Maintenance Tips for Sealing Machines

- Reducing TCO: Energy and Maintenance Tips for Sealing Machines

- Understanding TCO for Sealing Machines and the Role of a Sealing Machine

- Why Energy Efficiency Matters for a Sealing Machine

- Select the Right Machine: Match Capacity to Demand

- Optimize Cycle Parameters and Use Energy-Saving Modes

- Control and Monitor Power Use: Instrumentation and Data

- Compressed Air Management for Pneumatic Sealing Machines

- Heating and Thermal Efficiency in Sealing Process

- Preventive Maintenance: A Checklist to Reduce Downtime

- Use OEM Parts and Standardize Critical Spares

- Implement Predictive Maintenance Using Condition Monitoring

- Operator Training and Standard Operating Procedures (SOPs)

- Tooling, Changeovers and Quick-Change Techniques

- Evaluate Upgrades and Retrofits: When to Replace vs Repair

- Cost Comparison Table: Repair vs. Retrofit vs. Replace

- Regulatory and Environmental Considerations

- Brand Focus: Why Choose Yuanyang's Automatic Tube Sealing Machine for Sale

- Implementation Roadmap: 90-Day Plan to Cut TCO

- FAQ — Common Questions about Sealing Machines and Reducing TCO

- Q1: How much energy can I realistically save by optimizing my sealing machine?

- Q2: What spare parts should I keep on hand for a sealing machine?

- Q3: How often should I calibrate filling systems on tube sealing machines?

- Q4: Is it worth retrofitting my old sealing machine instead of buying new?

- Q5: How does the Automatic Tube Sealing Machine for Sale reduce maintenance workload?

- Contact Us / View Product

- References and Authoritative Sources

Reducing TCO: Energy and Maintenance Tips for Sealing Machines

Understanding TCO for Sealing Machines and the Role of a Sealing Machine

Total Cost of Ownership (TCO) for a sealing machine goes beyond initial purchase price. TCO includes energy consumption, maintenance and downtime, spare parts, labor, consumables, and eventual disposal or resale. For manufacturers using a sealing machine—especially integrated options like the Automatic Tube Sealing Machine for Sale—reducing TCO means optimizing every stage from installation to end-of-life. This article provides actionable energy and maintenance tips grounded in industry practice to help you lower operating costs while maintaining throughput and product quality.

Why Energy Efficiency Matters for a Sealing Machine

Energy is one of the largest variable costs in many production lines. Sealing machines that operate continuously or at high cycle rates can be significant energy consumers. Energy efficiency reduces utility bills and lowers carbon footprint—both financially and from a sustainability reporting perspective. When evaluating or operating an Automatic Tube Sealing Machine for Sale, target a combination of equipment-level upgrades, control strategies, and process changes to reduce per-unit energy use without sacrificing performance.

Select the Right Machine: Match Capacity to Demand

Choosing the correct sealing machine size and capabilities prevents overconsumption of energy. An oversized machine may idle frequently and burn energy inefficiently; an underpowered machine may cause bottlenecks and raise labor or overtime costs. Assess production volumes, peak demand, and future growth. The Yuanyang Automatic Tube Sealing Machine for Sale is available as an integrated automatic filling and sealing solution for aluminum or plastic tubes, which can reduce auxiliary equipment and lower TCO when properly matched to throughput requirements.

Optimize Cycle Parameters and Use Energy-Saving Modes

Adjusting cycle speed, heater setpoints, and pneumatic timings can significantly reduce energy consumption. Many modern sealing machines support variable speed drives, programmable logic controllers (PLC), and standby or sleep modes. Implement machine-specific energy-saving profiles that automatically reduce heater power and air compressor demand during planned stops or low-volume shifts. For sealing machines with pneumatic filling control—like the Yuanyang model—optimize actuation timing to minimize compressed air use.

Control and Monitor Power Use: Instrumentation and Data

Install energy meters and integrate them with your supervisory systems to measure real-time energy use of the sealing machine. Monitoring lets you identify spikes, idle losses, and inefficiencies. Use the data to create benchmarks and set improvement targets. Simple dashboards help line supervisors make informed decisions: e.g., adjusting shift schedules to avoid starting multiple high-draw machines simultaneously, or identifying machines needing maintenance due to abnormal energy patterns.

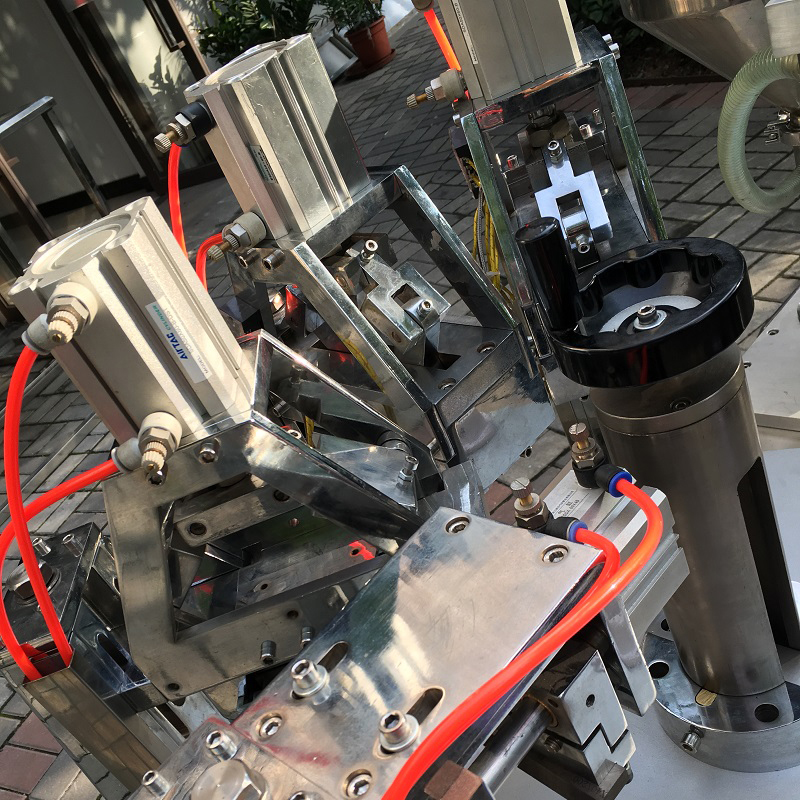

Compressed Air Management for Pneumatic Sealing Machines

Compressed air is often a hidden cost. Many sealing machines rely on pneumatic systems for filling, clamping, and sensing. Implement these practical steps: repair leaks promptly, install efficient compressors with variable speed drive (VSD), use local air storage and pressure regulators near the sealing machine, and consider replacing pneumatic actuators with electric actuators where feasible. Pneumatic filling control on the Yuanyang Automatic Tube Sealing Machine for Sale is accurate; ensuring the compressed air system is efficient preserves that accuracy while minimizing cost.

Heating and Thermal Efficiency in Sealing Process

Sealing machines that rely on thermal elements (induction heaters, hot bars) can be optimized by ensuring proper insulation, rapid-response heaters, and PID control loops for minimal overshoot. Reduce preheat time through improved temperature control and use thermal imaging or contact sensors to validate even heat distribution across sealing surfaces. Periodic calibration ensures setpoints remain accurate, reducing scrap and rework.

Preventive Maintenance: A Checklist to Reduce Downtime

Planned preventive maintenance (PM) reduces unplanned downtime and extends component life—two direct contributors to lower TCO. A PM checklist for sealing machines should include:

- Daily: visual inspection, cleaning sealing jaws, checking photoelectric sensors, verifying proper tube alignment.

- Weekly: lubrication of moving parts, checking pneumatic tubing and fittings for leaks, verifying heater elements and thermocouples.

- Monthly: inspect belts and drives, validate PLC error logs, check electrical connections and grounding, clean and test air filters and regulators.

- Quarterly: calibration of fill volumes, test spare parts inventory, update firmware/controls if recommended by the manufacturer.

Keeping a PM log helps correlate maintenance actions with performance data and energy use.

Use OEM Parts and Standardize Critical Spares

Stocking a short list of critical spares minimizes downtime. Typical spare parts for sealing machines include heater elements, temperature sensors, pneumatic seals, solenoid valves, and photoelectric sensors. Using OEM or OEM-equivalent parts preserves machine performance and may avoid warranty issues. Create a prioritised spare parts matrix based on Mean Time To Repair (MTTR) and part lead times.

Implement Predictive Maintenance Using Condition Monitoring

Predictive maintenance uses vibration sensors, thermography, and electrical monitoring to identify failing components before they cause outages. For example, rising current draw on a motor can indicate bearing wear. Adding simple condition monitoring to sealing machines lets maintenance teams act based on condition rather than fixed time intervals, often reducing total maintenance cost and unplanned downtime.

Operator Training and Standard Operating Procedures (SOPs)

Properly trained operators reduce misfeeds, jams, and incorrect settings that lead to scrap and extra maintenance. Develop SOPs for start-up, changeover, sanitation, and shutdown. Include energy-conscious behaviors: group production runs to avoid frequent start/stops, apply correct warm-up procedures, and use energy-saving machine modes. The touchscreen operation and humanized design of the Yuanyang Automatic Tube Sealing Machine for Sale make it easier to train operators faster and reduce user errors.

Tooling, Changeovers and Quick-Change Techniques

Reducing changeover time minimizes downtime and labor costs. Implement quick-change tooling, use modular fixtures, and maintain a clear setup checklist. Document changeover time as a KPI and aim to reduce it using lean methods (SMED). Less downtime during changeovers also reduces wasted energy from idling equipment.

Evaluate Upgrades and Retrofits: When to Replace vs Repair

Sometimes a retrofit or control upgrade delivers faster ROI than continued repairs. Consider the following when deciding to upgrade to a newer sealing machine or retrofit an existing unit: energy savings from new drives/heaters, improved throughput, reduced spare parts costs, and new functions like remote monitoring. Use a simple payback or lifecycle cost calculation to compare options. For many manufacturers, investing in an integrated solution such as the Automatic Tube Sealing Machine for Sale is attractive because it consolidates filling and sealing functions—reducing auxiliary equipment needs and simplifying maintenance.

Cost Comparison Table: Repair vs. Retrofit vs. Replace

| Option | Typical Upfront Cost | Energy Savings | Downtime Risk | Maintenance Complexity |

|---|---|---|---|---|

| Repair (component) | Low | None to small | Moderate | Moderate |

| Retrofit (controls, drives) | Medium | Moderate to high | Low to moderate | Low (modernized) |

| Replace (new machine) | High | High | Low (warranty period) | Low to medium |

Regulatory and Environmental Considerations

Sealing machines in food, cosmetics, or pharmaceutical production must meet hygiene and regulatory standards. Compliance reduces risk of costly recalls and rework. Ensure materials in contact with product are compliant (e.g., FDA-compliant components for food/medicine). Environmental considerations—waste reduction, recyclable packaging, and energy reporting—also impact corporate sustainability goals and can translate to incentives or lower regulatory risk.

Brand Focus: Why Choose Yuanyang's Automatic Tube Sealing Machine for Sale

Yuanyang's automatic tube sealing machine combines filling and sealing in a compact, integrated platform suitable for cosmetics, food, medicine, and chemical sectors. Key advantages that reduce TCO include:

- Touchscreen operation and humanized design for rapid operator onboarding and fewer user errors.

- Pneumatic filling control to ensure accurate fills and reduce product waste.

- Photoelectric sensing and pneumatic linkage control for consistent sealing and reduced rejects.

- Efficient pneumatic control valves and separable runners for easier cleaning and maintenance.

These design choices translate into lower labor costs, reduced scrap, and simpler maintenance—direct contributors to lower TCO.

Implementation Roadmap: 90-Day Plan to Cut TCO

Follow this roadmap to realize quick wins in energy and maintenance:

- Days 1–15: Baseline measurement—install energy and air meters, capture current PM logs, and map processes.

- Days 16–45: Quick fixes—repair air leaks, tune heater PID loops, update SOPs, and provide operator training.

- Days 46–75: Medium actions—implement predictive monitoring, optimize cycle parameters, and stock critical spares.

- Days 76–90: Evaluate upgrades—run ROI for retrofits or replacement with an integrated solution like Yuanyang’s Automatic Tube Sealing Machine for Sale.

FAQ — Common Questions about Sealing Machines and Reducing TCO

Q1: How much energy can I realistically save by optimizing my sealing machine?

Energy savings vary by baseline efficiency and implemented measures. Practical improvements (repairing leaks, tuning controls, scheduling) commonly yield 5–20% savings. Retrofits or replacement with modern equipment can yield 20–50% energy reduction in some cases, depending on age and technology of the replaced machine.

Q2: What spare parts should I keep on hand for a sealing machine?

Essential spare parts include heater elements, thermocouples, photoelectric sensors, solenoid valves, pneumatic seals, O-rings, and key electrical components. Prioritize items with long lead times or that are critical to operation.

Q3: How often should I calibrate filling systems on tube sealing machines?

Calibration frequency depends on usage and product criticality. A common approach is monthly checks for high-volume lines and quarterly checks otherwise. Immediately recalibrate after any repair affecting fill systems or if quality drift is observed.

Q4: Is it worth retrofitting my old sealing machine instead of buying new?

Often yes, if the frame and mechanical systems are sound. Retrofitting controls, drives, or replacing heaters can be cost-effective with a short payback. If multiple systems are outdated or energy savings potential is high, replacement may be preferable. Run lifecycle cost analysis to decide.

Q5: How does the Automatic Tube Sealing Machine for Sale reduce maintenance workload?

The Yuanyang machine’s modular design, separable runners for cleaning, pneumatic filling control, and touchscreen interface simplify daily cleaning, troubleshooting, and operator interaction—reducing time spent on routine maintenance and changeovers.

Contact Us / View Product

To evaluate how the Automatic Tube Sealing Machine for Sale can lower your TCO, contact our sales team or request a demo. Our experts will help size equipment to your needs, estimate energy and maintenance savings, and provide a tailored ROI analysis.

References and Authoritative Sources

- Packaging machine — Wikipedia: https://en.wikipedia.org/wiki/Packaging_machine

- Industrial Energy Management — U.S. Department of Energy, Advanced Manufacturing Office: https://www.energy.gov/eere/amo/industrial-energy-management

- Total cost of ownership — Wikipedia: https://en.wikipedia.org/wiki/Total_cost_of_ownership

- Energy Efficiency and Renewable Energy — U.S. Department of Energy: https://www.energy.gov/eere/office-energy-efficiency-renewable-energy

- ISO 9001 — Quality management systems — ISO: https://www.iso.org/iso-9001-quality-management.

OEM/ODM flash mixing tank Manufacturers and Suppliers

Best vacuum emulsifying mixer machine suppliers manufacturers and supplier brands

Best professional emulsifier machine for food manufacturers and supplier brands

How to Choose Right continuous powder mixer manufacturer and supplier in America?

Automatic Piston Filling Machine

What material can the piston filling machine fill?

The piston filler can fill a variety of viscous liquids and pastes, such as laundry detergent, shampoo, hair conditioner, toothpaste, gel water, aloe vera gel, lotion and other washing and care products, honey, loquat paste, mother-herb paste, ketchup, salad dressing and other food.

One Stage Water Treatment

When do you recommend pvc type and stainless steel type?

Regarding price, pvc type is cheaper, if client wants to save cost, can choose pvc type; regarding quality, stainless steel type is better, especially in too cold temperature,better resistance to low temperature.

Food

What are the maintenance cycles and requirements for the equipment?

The maintenance cycle and requirements vary depending on usage frequency and conditions. We provide detailed maintenance manuals and offer regular checkups and maintenance services as needed.

Horizontal Filling Machine

What kind of liquids does this liquid bottling machine can fill?

It can fill various liquids products, such shampoo, cream, conditioner, detergent, lotion, sauce, and so on. The materials must be easy to flow down for this cream filler machine. For too viscous paste, pressurized filling machine or hot filling machine will be recommended based on materials. Please send your materials to check.

Chemicals

What types of chemical components does the equipment support?

The equipment can handle liquids, powders, granules, and other components, depending on the equipment model.

Sachet Packaging Machine for Sale

Yuanyang sachet packaging machine is a kind of automatic equipment, mainly used for measuring, filling, and sealing small bag packing materials. The sachet packing machine has become an indispensable piece of equipment in modern production for food, medicine, chemicals, and other fields.

Features:

⦁ Microcomputer controlled;

⦁ Automated fast speed;

⦁ Multi-function integration.

Powder Sachet Packaging Machine for Sale

Yuanyang sachet packaging machine is a kind of automatic equipment for packing powder, mainly used for measuring, filling, and sealing small bag packing materials. The sachet packing machine has become an indispensable piece of equipment in modern production for food, medicine, chemicals, and other fields.

Features:

⦁ Microcomputer controlled;

⦁ Automated fast speed;

⦁ Multi-function integration.

50L Hydraulic Lift Vacuum Emulsifier

Yuanyang hydraulic lift vacuum emuslifier is a combined mixing equipment with a main vacuum homogenizer tank, a water tank, and an oil tank, which is an integrated equipment with a mixing, dispersing, homogenizing, emulsifying, vacuumizing and powder absorption system that is widely used in cosmetics, food, pharmaceutical, and chemical fields.

Features:

⦁ With a hydraulic lift lid & tilting pot, vacuum system, and electric control system.

⦁ Suitable for products of 10,000~50,000 cps viscosity.

⦁ Perfect particle size of 2 microns and evenly distributed.

Vacuum Emulsifying Mixer for Sale

Yuanyang vacuum emulsifying mixer is a kind of emulsifier machine, the most popular cosmetics production equipment for making cream, skin-care products, ointment, paste, and emulsions.

Features:

⦁ Composed of a main emulsifying pot, a water pot, and an oil pot.

⦁ With a hydraulic lifting system, vacuum system, and electric control system.

⦁ Suitable for products of 10,000~50,000 cps viscosity.

⦁ Perfect particle size of 2 microns and evenly distributed.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery