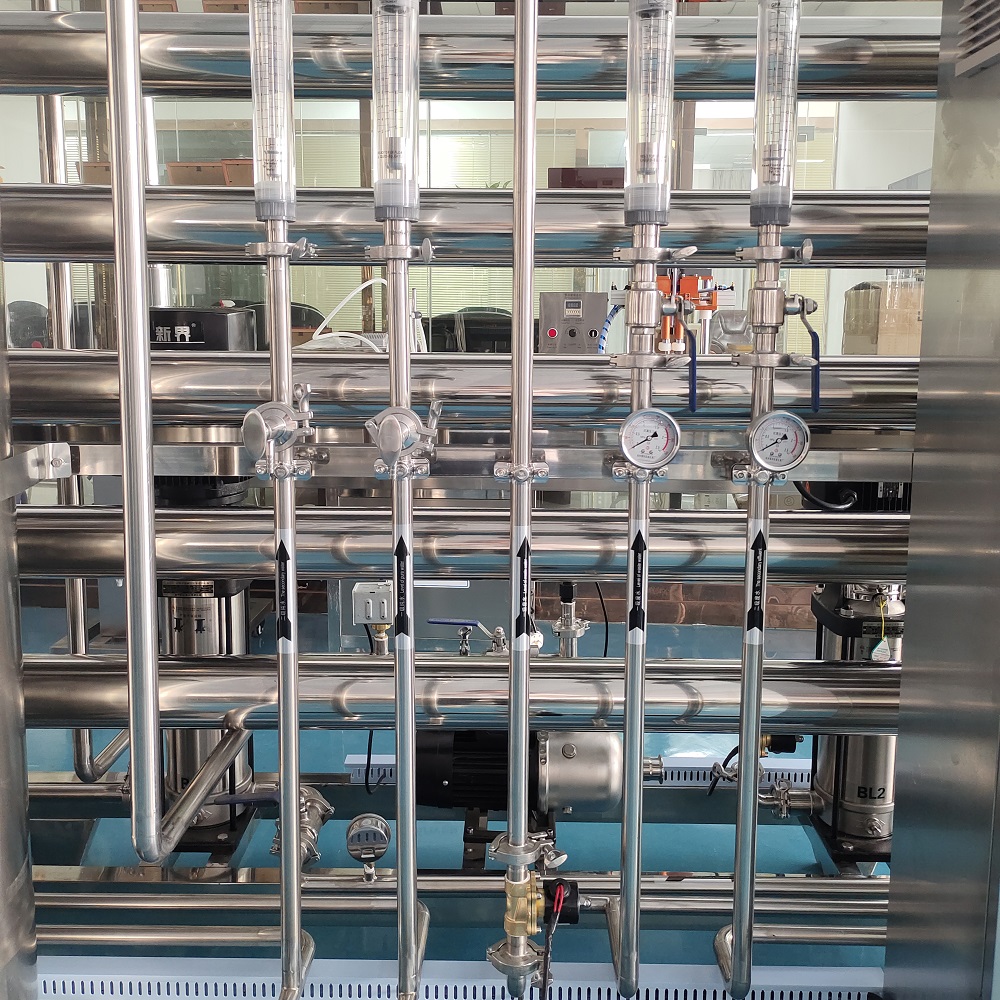

RO Water Treatment Equipment

RO Water Treatment Equipment for Industrial Applications

Reliable Purification for a Wide Range of Industries

YUANYANG’s advanced RO water treatment equipment offers efficient and consistent water purification for demanding industrial environments. Whether you manufacture pharmaceuticals, food, cosmetics, or chemical products, our systems ensure high-quality water—free from contaminants, ions, and impurities—every cycle.Cutting-edge Technology and Easy Operation

Our RO water treatment equipment features robust construction, user-friendly controls, and energy-efficient operation. The high-performance reverse osmosis process removes up to 99% of dissolved solids, microbes, and pollutants, providing purified water that meets the most stringent production requirements.Integrated Turnkey Solutions

YUANYANG supplies a full set of complementary equipment, including industrial mixers, storage tanks, filling machines, and beyond. Our RO water treatment systems are designed to seamlessly integrate into your production line, delivering consistently reliable operation with minimal downtime. Plus, we provide free technical training and comprehensive installation support.Certified Quality and Outstanding Support

YUANYANG’s equipment is CE certified for safety and durability. With expert engineering, ongoing after-sales service, and a global vision, we are committed to helping you achieve superior water quality and operational excellence.Trust YUANYANG for Industrial-Grade Water Purification

Choose YUANYANG’s RO water treatment equipment to safeguard your processes and your products. From small-scale applications to full-scale factory integration, our solutions provide the purity and performance your business demands.ro water treatment equipment Display

Does the tank with mixer also has heater?

The model is non-heating type, the heating mixer tanks is another type with 3 layers, a heating jacket and an insulation jacket.

Can the filling machine be connected with other machines, such as capping machine, bottle sorting machine?

Yes, this pneumatic filling machine is one of the complete filling line machines, user can tell the conveyor height of his current machine, we shall customize accordingly. If client buy a complete line from us, we will make every machine in a line or according to space.

Are the equipment compliant with industry regulations?

Yes, Yuanyang’s equipment meets GMP, FDA, and other relevant industry regulations, ensuring high-quality and safety standards.

What’s the production time of this semi automatic filler?

Normally it only takes 2-7 days to produce. Most often the popular 100-1000g filling range type is in stock.

Is the powder packing machine suitable for different film size?

The standard sachet packing machine for powders is only suitable for one film size, and module must be customized according to the film width. But client can require more set of module to replace for different film width.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery