Industrial Water Treatment & Reverse Osmosis Solutions

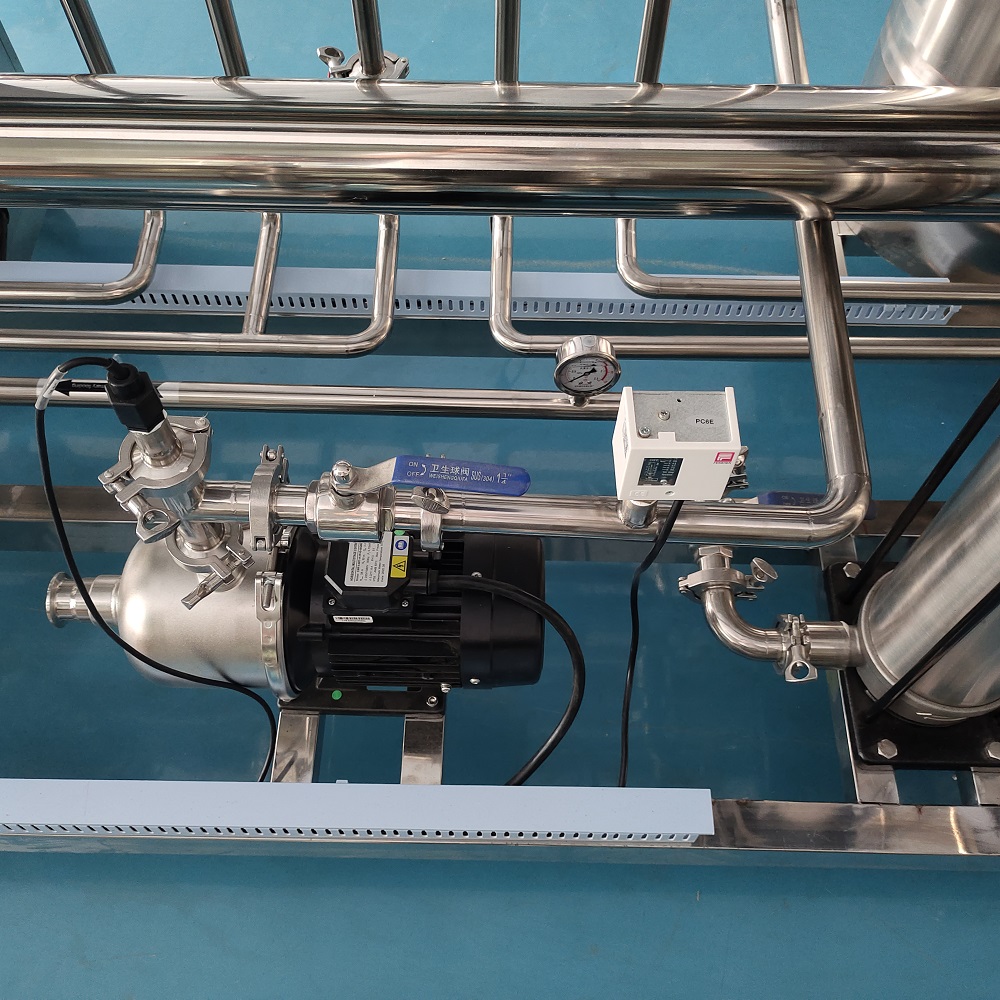

Industrial Water Treatment & Reverse Osmosis Systems from YUANYANG

Advanced Water Purification Technologies

YUANYANG specializes in high-efficiency water treatment and reverse osmosis systems, designed for diverse industrial and manufacturing needs. Our advanced equipment ensures optimal water purity, supporting various production lines and enhancing operational safety.

Benefits of Reverse Osmosis in Water Treatment

Reverse osmosis is a proven method for removing impurities, minerals, and contaminants from water. YUANYANG’s reverse osmosis units enable your operation to achieve consistent water quality, ensuring protection for sensitive equipment and product formulas. This results in reduced maintenance, extended system lifespan, and improved production quality.

Integrated Solutions for Complete Production Lines

With years of expertise, YUANYANG delivers more than just water treatment machinery. Our product range includes mixers, blenders, storage tanks, filling and capping machines, as well as labeling and coding solutions. All our water treatment and reverse osmosis equipment seamlessly integrate with your existing YUANYANG production lines, enabling hassle-free operation and maximum efficiency.

Reliable Quality and Global Certification

At YUANYANG, safety and reliability are our commitments. Our water treatment and reverse osmosis systems carry CE certifications, underlining compliance with stringent European safety and health standards. Clients benefit from robust machinery, professional technical training, and one-stop turnkey project support—making YUANYANG your trusted partner for water purification and industrial process solutions.

Choose YUANYANG for leading-edge industrial water treatment and reverse osmosis technology—enabling cleaner water, stronger production, and lasting performance. Contact us for expert consultation today!

water treatment reverse osmosis Display

How do you handle unexpected downtime or failures during production?

Our equipment is equipped with an intelligent fault detection system that monitors the operational status in real-time, automatically alerts and stops operation when issues arise, ensuring safety. Additionally, our technical support team offers 24/7 remote and on-site services to quickly address equipment failures.

What’s the thickness of the stainless steel tank for liquids?

The standard thickness for finished products is 3mm, the water tank thickness is 2mm. But the bigger capacity, the layer will be thicker.

Can you customized contact materials stainless steel 316L for the detergent powder making machine ?

Yes, we provide customization service upon requirements. The contact parts can be SUS304 or SUS316L. But the cost will be more.

What the difference between hydraulic lifting vacuum mixer and fixed lid vacuum mixer?

The main different between the two types of equipment is on the main emulsifier pot. The main pot of hydraulic lifting emulsifier can tilt down to empty materials. The hydraulic system helps to lift the main pot cover up, then the main pot can tilt down. But the fixed lid type has no this function.

What’s the designed capacity and working capacity for the 500L hydraulic vacuum mixer?

The designed capacity is 540 liters, the working capacity is 500 liters.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery