Integrating Automatic Tube Sealers into Automated Packaging Lines

- Integrating Automatic Tube Sealers into Automated Packaging Lines — sealing machine best practices

- Why integrate a sealing machine into your automated packaging line?

- Understanding the Automatic Tube Sealing Machine for Sale — product overview

- Key technical considerations when integrating a sealing machine (sealing machine)

- Layout and mechanical integration: conveyors, pick-and-place, and indexing

- Controls, communication, and automation protocols (PLC, OPC-UA)

- Quality assurance and process control: sensors, vision, and traceability

- Materials compatibility and sealing methods: aluminum vs plastic tubes

- Safety, maintenance, and cleaning practices for sealing machines

- ROI and productivity: quantifying the impact of adding an automatic tube sealer

- Case studies and typical applications across industries

- Why choose Yuanyang's Automatic Tube Sealing Machine for Sale — brand advantages

- Implementation checklist: step-by-step for successful integration of a sealing machine

- FAQ — Frequently Asked Questions about sealing machine and Automatic Tube Sealing Machine for Sale

- Q: What tube types can an Automatic Tube Sealing Machine handle?

- Q: How fast can an integrated tube sealing machine run?

- Q: Can the sealing machine be integrated into an existing line?

- Q: What sanitation standards does Yuanyang support for food and pharma?

- Q: What maintenance is required?

- Q: How do I evaluate ROI?

- Next steps — Contact sales or view the product

- Authoritative references and further reading

- Contact & product CTA

Integrating Automatic Tube Sealers into Automated Packaging Lines — sealing machine best practices

Why integrate a sealing machine into your automated packaging line?

Integrating a sealing machine into an automated packaging line reduces labor, improves consistency, and raises throughput while ensuring sealing quality for sensitive products. Whether you run cosmetics, food, pharmaceuticals, or chemicals production, moving from semi-manual or stand-alone sealing to a fully integrated Automatic Tube Sealing Machine can cut cycle time, reduce waste, and deliver repeatable seal integrity — critical for safety, shelf life, and brand reputation. Choosing the right machine also depends on material compatibility, ensuring that your tube sealing machine suits various formulations and packaging materials without compromising seal quality.

Understanding the Automatic Tube Sealing Machine for Sale — product overview

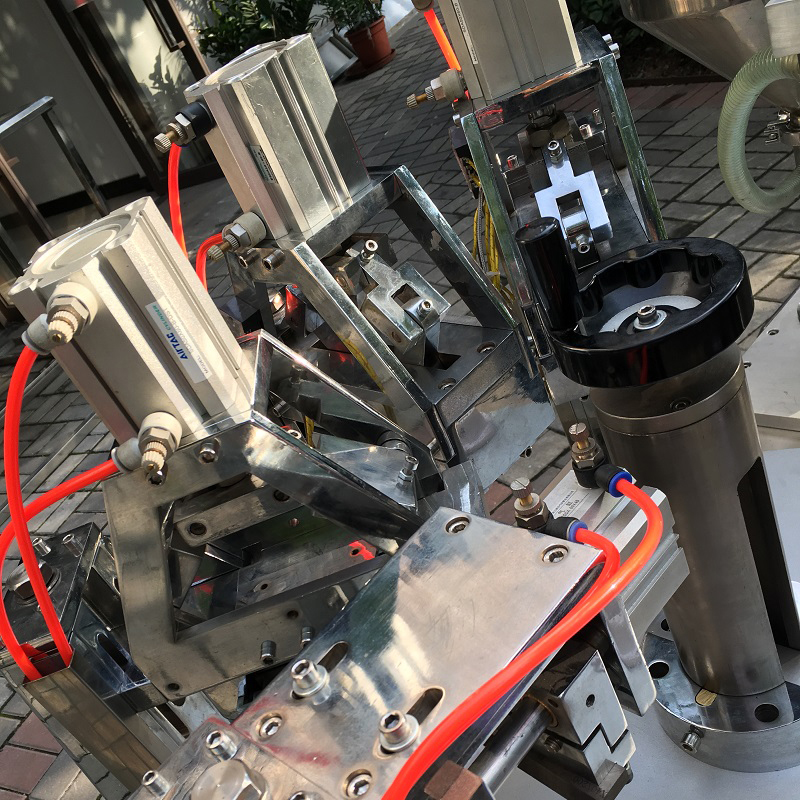

Yuanyang's Automatic Tube Sealing Machine for Sale is an integrated automatic packaging machine with filling and sealing capability for aluminum or plastic tubes. The machine combines precise pneumatic filling control with reliable sealing, making it suitable for a wide range of viscous and semi-viscous formulations used in cosmetics, food, medicine, and chemical industries.

Core product highlights:

- Touchscreen operation with humanized design for intuitive setup and changeover.

- Pneumatic filling control to ensure accurate, repeatable fill volumes across tube sizes.

- Photoelectric sensing and pneumatic linkage control for reliable part tracking.

- Pneumatic control valve system: efficient, safe, and allowing the runner to be adjusted and cleaned separately.

Key technical considerations when integrating a sealing machine (sealing machine)

Before integration, evaluate these technical points to ensure smooth operation and avoid costly downtime:

- Throughput matching: Confirm the sealing machine's cycle/sec aligns with upstream filling and downstream secondary packaging to prevent bottlenecks.

- Tube geometry and materials: Verify the machine supports your tube diameters, lengths, and whether tubes are plastic laminate or aluminium — these affect sealing parameters.

- Sealing method compatibility: Heat crimp, induction, ultrasonic or rotary crimping behave differently. Ensure the selected machine supports the required method for product integrity.

- Environmental control: Some products require humidity or temperature control during sealing to prevent defects.

- Sanitation and cleanability: For food and pharma, materials and design must allow CIP (clean-in-place) or easy disassembly for cleaning.

Layout and mechanical integration: conveyors, pick-and-place, and indexing

Mechanical layout determines the reliability of product flow. Plan the infeed (single-track vs multi-track), orientation stations (for cap or nozzle-first), and outfeed conveyors that feed to secondary operations (cartoning, labeling). Typical integration elements include:

- Infeed accumulation conveyor with gentle transitions to prevent tube deformation.

- Orientation module (rotary or linear) to align the crimp end for consistent sealing.

- Timing/indexing belt connecting filler to sealing station to tightly control position.

- Reject station after quality inspection to remove defective units automatically.

Controls, communication, and automation protocols (PLC, OPC-UA)

Modern sealing machines must communicate with the line control system. Confirm the machine supports common industrial protocols (e.g., Modbus, EtherNet/IP, PROFINET, OPC-UA) and has a robust PLC architecture. Benefits include:

- Centralized HMI monitoring and recipe management for quick product changeovers.

- Real-time OEE and performance metrics exportable to MES/SCADA systems.

- Alarm logging and remote diagnostics to speed up troubleshooting and reduce downtime.

Quality assurance and process control: sensors, vision, and traceability

Consistent sealing is non-negotiable. Integrate process controls such as photoelectric sensors (as featured in Yuanyang machines), torque monitors, and optional vision systems for surface inspection and crimp shape analysis. Typical QA elements:

- Photoelectric sensors to confirm tube presence and correct position prior to sealing.

- Force/pressure monitoring on crimp or sealing head to detect under/over seals.

- Vision inspection to detect surface defects, missing caps, or misaligned crimps.

- Batch traceability via barcode or inkjet printers integrated inline for regulatory compliance.

Materials compatibility and sealing methods: aluminum vs plastic tubes

Sealing parameters differ by material:

- Aluminum tubes: Typically use mechanical crimping and sometimes heat to form a permanent end. Control of crimp profile is essential for consumer safety.

- Plastic tubes (laminate or mono-layer): Often sealed using heat welding or ultrasonic methods. Temperature control and dwell time are critical to avoid seal lapses or material damage.

Yuanyang's machine supports both aluminum and plastic tubes, with adjustable runners and pneumatic control valves that make switching between formats faster and cleaner.

Safety, maintenance, and cleaning practices for sealing machines

Safety interlocks, emergency stops, and guarding are required. Maintenance best practices include scheduled checks for pneumatic valves, wear parts on sealing jaws, and regular calibration of filling pistons. Because the Yuanyang design allows the runner to be adjusted and cleaned separately, cleaning cycles are faster and more thorough — reducing cross-contamination risk.

ROI and productivity: quantifying the impact of adding an automatic tube sealer

To justify investment, compare manual or semi-automatic setups with an integrated automatic sealing machine. Typical measurable improvements include labor reduction, yield increase, and throughput improvement.

| Metric | Manual/Semi-automatic | Automatic Integrated Sealing Machine |

|---|---|---|

| Throughput (tubes/min) | 10–30 | 60–200+ |

| Labor per shift | 2–5 operators | 0–1 operators (monitoring) |

| Seal defect rate | 1–5% | <0.5% |

| Changeover time | 30–90 minutes | 5–30 minutes |

| Typical payback | — | 6–24 months (depending on production scale) |

Note: Actual numbers depend on product viscosity, tube size mix, and line design. Use pilot runs to confirm throughput estimates.

Case studies and typical applications across industries

Industries where integrated tube sealing machines deliver immediate value:

- Cosmetics: Lotions, creams, and serums that require precise fills and attractive crimps for High Quality appearance.

- Food: Condiments, pastes, and sauces where seal integrity affects shelf life.

- Pharmaceuticals: Ointments and topical formulations where contamination prevention and traceability are vital.

- Chemicals: Adhesives and gels requiring robust seals to prevent leakage during transport.

Why choose Yuanyang's Automatic Tube Sealing Machine for Sale — brand advantages

Yuanyang offers a reliable combination of automation, intuitive controls, and sanitary design tailored to modern production environments:

- Integrated design: Filling and sealing in one machine eliminates transfer points where errors or contamination can occur.

- User-friendly HMI: Touchscreen operation shortens training time and reduces operator errors.

- Precise pneumatic filling: Delivers consistent fills with easy adjustments for multiple tube sizes.

- Photoelectric sensing & pneumatic linkage: Ensures accurate part detection and synchronized sealing actions.

- Maintainability: Pneumatic control valves and separable runners mean quicker cleaning and lower downtime.

Implementation checklist: step-by-step for successful integration of a sealing machine

Follow this checklist to minimize risks during integration:

- Define throughput targets and product formats (tube dimensions, materials, contents).

- Map the mechanical layout: infeed, orientation, sealing, outfeed, and reject stations.

- Confirm electrical and pneumatic utilities match machine requirements (pressure, flow, voltage).

- Specify control integration protocol (PLC/MES interfaces) and data points required.

- Plan acceptance criteria: seal integrity tests, visual standards, and production run trials.

- Train operators on HMI, changeovers, cleaning, and basic troubleshooting.

- Schedule preventive maintenance and parts inventory for wear items (sealing jaws, valves).

FAQ — Frequently Asked Questions about sealing machine and Automatic Tube Sealing Machine for Sale

Q: What tube types can an Automatic Tube Sealing Machine handle?

A: Modern machines, including Yuanyang's, typically handle both aluminum and plastic tubes in a defined size range. Confirm with the manufacturer the exact diameter and length limits for your SKU mix.

Q: How fast can an integrated tube sealing machine run?

A: Throughput varies by model and product. Integrated sealing lines commonly operate between 60 and 200+ tubes per minute. For precise figures, run a pilot with your product and tube format.

Q: Can the sealing machine be integrated into an existing line?

A: Yes. Integration requires matching infeed/outfeed geometry, aligning control communication (PLC protocols), and ensuring utilities (air, power) meet specifications. A site survey is recommended.

Q: What sanitation standards does Yuanyang support for food and pharma?

A: Yuanyang machines use materials and designs that facilitate cleaning: separable runners, hygienic surfaces, and pneumatic components that reduce contamination risk. For regulated pharma lines, additional validation and compliance features can be specified.

Q: What maintenance is required?

A: Routine checks include inspecting sealing jaws, replacing wear parts, verifying pneumatic valve seals, and calibrating fill volumes. Regular cleaning cycles should be scheduled based on product and regulatory needs.

Q: How do I evaluate ROI?

A: Compare current labor and defect costs to projected outputs after automation. Consider reduced waste, increased throughput, and lower labor as part of the payback calculation. Typical payback periods range from 6–24 months depending on scale.

Next steps — Contact sales or view the product

If you are ready to evaluate an Automatic Tube Sealing Machine for Sale or wish to request a site survey, contact our sales team for a tailored quote, pilot run, and a line-integration plan. For product details, specifications, and to arrange demonstrations, reach out today.

Authoritative references and further reading

- Wikipedia — Tube (container): https://en.wikipedia.org/wiki/Tube_(container)

- Wikipedia — Packaging: https://en.wikipedia.org/wiki/Packaging

- International Organization for Standardization (ISO): https://www.iso.org

- U.S. Food & Drug Administration (FDA): https://www.fda.gov

- Packaging Machinery Manufacturers Institute (PMMI): https://www.pmmi.org

Contact & product CTA

To learn how Yuanyang's Automatic Tube Sealing Machine for Sale can improve your line's performance, email [email protected] or call +86-123-456-7890 to request specifications, a quotation, or a factory demonstration.

Comparing Homogenizer Mixer Designs for Consistent Soap Viscosity

What are the different types of inkjet printers?

What are the application scenarios of water filling machines?

Top reverse osmosis water treatment systems Manufacturers and Suppliers

Aluminum Foil Sealing Machine

What’s the maximum and minimum height can the automatic sealing machine lift up and go down?

The maximum height for the sealing head to the floor is 75-120cm.

Automatic powder feeder machine

What’s the hopper capacity of the feeding machine for powder?

The standard feeder hopper capacity is 150L, can be customized.

One Stage Water Treatment

What type of water can we use for this pure water filter ?

The raw quality (conductivity) should be ≤300μs/cm), such as city tap water, lake water, underground water, river water...

Horizontal Filling Machine

How long is the suction hose?

This hose is about 1.3 meters long. Can be longer upon requirements.

Liquid Mixing Tank

My products need specified paddle type to mixer,can you customize?

Yes,we can customized different mixing paddle type upon requirement. Just send your design to us to check.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery