Top Inline Homogenizer Manufacturers

# High Quality Inline Homogenizer Manufacturers – YUANYANG

Why Choose YUANYANG Homogenizers?

YUANYANG is a trusted inline homogenizer manufacturer with over 15 years of expertise in industrial mixing technology. Our homogenizers ensure ultra-fine particle reduction, uniform dispersion, and high efficiency—ideal for pharmaceuticals, cosmetics, and food processing. With CE-certified equipment, we guarantee compliance with EU safety standards.

Advanced Homogenizing Solutions

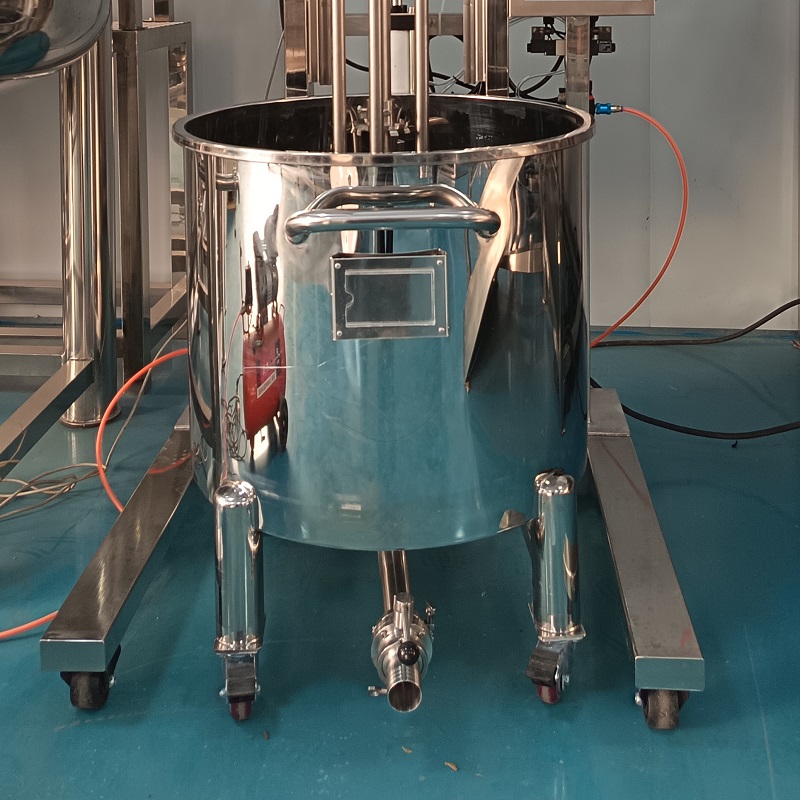

Our vacuum homogenizer mixers and high-shear mixers deliver superior emulsification, blending, and particle size reduction. Engineered for precision, YUANYANG’s machines feature robust stainless-steel construction, customizable configurations, and energy-efficient performance—perfect for demanding production environments.

Turnkey Production Line Support

Beyond homogenizers, YUANYANG provides complete production lines, including mixing tanks, filling machines, and labeling systems. Our one-stop solutions minimize downtime with seamless integration, free technical training, and installation support.

Global Compliance & Reliability

As a leading China-based industrial mixer factory, we hold multiple CE certificates, ensuring our homogenizers meet stringent EU regulations. Whether for small-scale labs or large-scale manufacturing, YUANYANG delivers reliability, innovation, and unmatched after-sales service.

Partner with YUANYANG Today

Upgrade your production with YUANYANG’s inline homogenizers—where cutting-edge technology meets cost-effective efficiency. Contact us for tailored solutions and global export support!

Keywords Integration: inline homogenizer manufacturers, vacuum homogenizer mixers, high-shear mixers, industrial mixer factory, CE-certified homogenizers.

Optimized for: SEO readability, Google ranking, and user engagement.

inline homogenizer manufacturers Display

Do you supply a complete set of liquid soap production line?

Yes, we supply the complete set of liquid soap production line, such as water treatment, liquid soap making machine, transfer pumps, storage tanks, filling machine, capping machine, sealing machine and labeling machine, and coding machine.

What minimum and maximum caps size can the bottle capper machine be suit for?

The cap diameter of standard 4 wheels capping machine is 20-75mm, but can be slightly customized according real cases.

Do you have a water pump with flow meter installed for the shampoo mixer machine?

Yes, water pump with flow meter can be added upon requirements.

Is the plastic bottle sealing machine also suitable for metal cap?

No, It is not suitable for metal cap, because the heat can’t go through the metal, the sealing won’t be achieved.

Can each nozzle be controlled separately?

Yes, each nozzle can be controlled separately.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery