Best Machines for Powder Sachet Packaging

- Why choose an automated sachet packaging machine?

- Speed, consistency and reduced labor costs

- Hygiene and contamination control

- Flexibility for different powder types

- Types of sachet packaging machines and how they compare

- Vertical form-fill-seal (VFFS) powder sachet machines

- Premade pouch sachet machines

- Auger vs. volumetric cup fillers for powders

- Feature checklist when selecting a sachet packaging machine

- Control system and automation

- Sealing, film compatibility and barrier performance

- Sanitation and maintenance

- Case study: Yuanyang Sachet Packaging Machine for Sale

- Where Yuanyang excels

- Recommended applications

- Comparison table: Popular sachet packaging machines for powder

- Regulatory and quality considerations

- Food and pharmaceutical compliance

- Traceability and serialization

- Validation and testing

- Practical tips for implementation and maintenance

- Pilot runs and production trials

- Operator training and spare parts

- Environmental control

- Buying guide & ROI considerations

- Calculate total cost of ownership (TCO)

- Scalability and future needs

- Supplier support and references

- FAQ

- Q1: What is the difference between VFFS and premade pouch sachet machines?

- Q2: How do I choose between auger and volumetric fillers?

- Q3: How important is microcomputer control on a sachet packaging machine?

- Q4: What certifications should packaging machines have for food and pharma?

- Q5: Can Yuanyang sachet packaging machines handle different sachet sizes?

Efficient powder sachet packaging relies on precise dosing, reliable sealing, and consistent bag formation. For manufacturers of single-serve powders — from instant coffee to powdered medicine and chemical samples — choosing the right sachet packaging machine ensures product protection, regulatory compliance, and minimal waste. This article examines leading technologies, practical selection criteria, and compliance considerations to help you select the best sachet packaging machine for sale and integrate it into modern production lines.

Why choose an automated sachet packaging machine?

Speed, consistency and reduced labor costs

Automated sachet packaging machines significantly increase output compared with manual packing. High-speed form-fill-seal and premade pouch machines can produce hundreds to thousands of sachets per minute depending on machine type and sachet format. Consistent operation reduces product giveaway (overfilling) and improves package uniformity — key for meeting customer expectations and regulatory tolerances.

Hygiene and contamination control

For food, nutraceuticals, and pharmaceuticals, sachet packaging machine designs prioritize clean contact surfaces, enclosed filling sections, and materials compatible with cleaning and sterilization protocols. Compliance with food safety management systems such as ISO 22000 (ISO 22000) and WHO Good Manufacturing Practice (WHO GMP) helps ensure safe production.

Flexibility for different powder types

Powder characteristics (flowability, particle size, hygroscopicity) affect machine choice: auger fillers and volumetric cup fillers suit free-flowing powders, while positive displacement or vacuum-assisted systems help meter cohesive or sticky powders. Choose a sachet packing machine that supports your powder’s handling needs and offers quick-change parts for cleaning and format shifts.

Types of sachet packaging machines and how they compare

Vertical form-fill-seal (VFFS) powder sachet machines

VFFS machines form sachets from rollstock film, fill, and seal vertically. They are compact and ideal for single-serve sachets such as sugar, instant beverage powder, or seasoning. Many modern VFFS units are microcomputer controlled, enabling precise control of bag length, cut timing, and multi-function integration.

Premade pouch sachet machines

Premade pouch machines handle already formed sachets and are suitable when you need printed or pre-laminated pouches with complex barrier properties. They typically provide pick-and-place filling, which is gentler for fragile products or when accurate net weight is critical.

Auger vs. volumetric cup fillers for powders

Auger fillers are preferred for fine, free-flowing powders where volume-to-weight repeatability is required. Volumetric cup fillers excel at larger dose sizes and simpler setups. For highly hygroscopic powders, consider nitrogen flushing and controlled-environment hoppers to preserve product quality during filling.

Feature checklist when selecting a sachet packaging machine

Control system and automation

Look for PLC or microcomputer-controlled systems with touchscreen HMI for recipe memory and fast changeover. Features such as servo-driven dosing, electronic weigh-checks, and ethernet connectivity allow integration into smart factories and Industry 4.0 data collection.

Sealing, film compatibility and barrier performance

Sealing type (heat-seal, ultrasonic) must match your film structure. Multi-layer laminates give excellent moisture and oxygen barriers for powder stability. Validate seal strength under expected storage and transportation conditions, and choose machines with adjustable sealing parameters for different films.

Sanitation and maintenance

Sanitary design reduces cross-contamination risk and simplifies cleaning. Quick-release parts, stainless steel 304/316 contact surfaces, and IP-rated electrical enclosures are important. Consider CIP-friendly components for food or pharmaceutical production where frequent cleaning or validation is necessary.

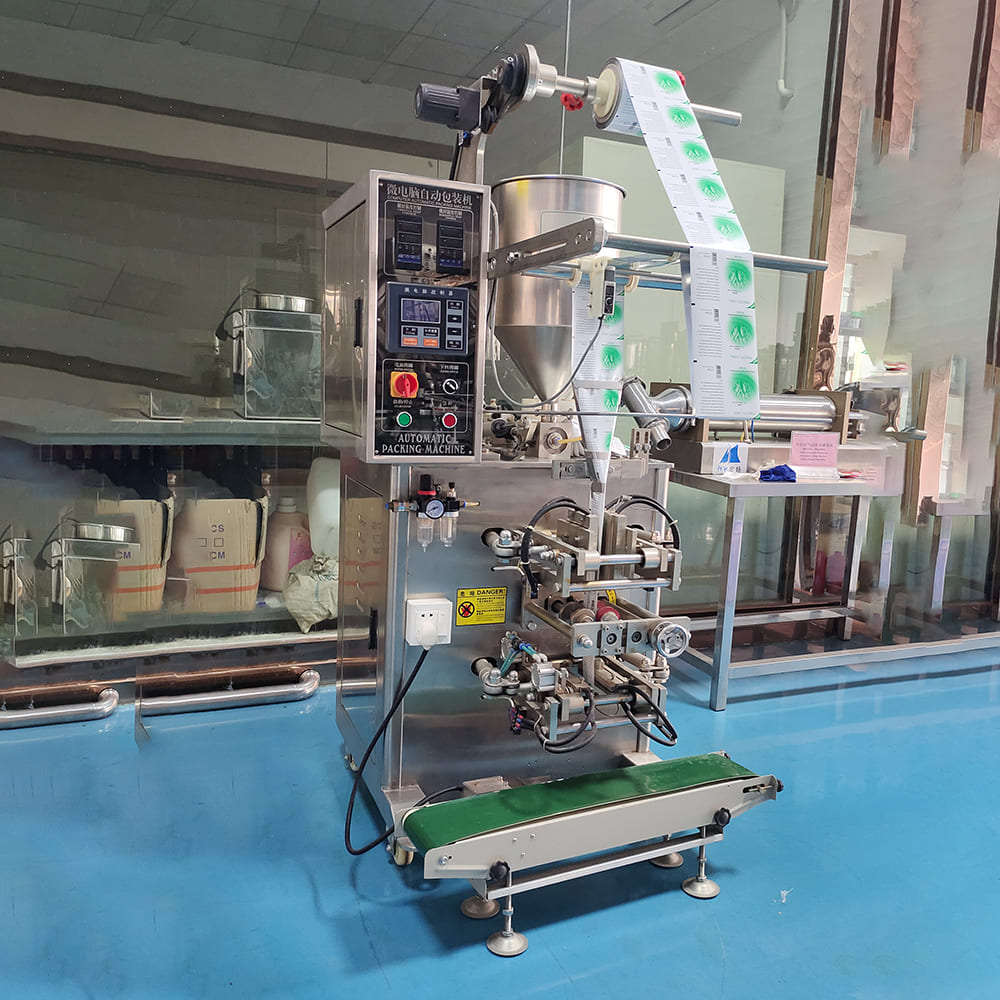

Case study: Yuanyang Sachet Packaging Machine for Sale

Yuanyang sachet packaging machine is a kind of automatic equipment, mainly used for measuring, filling, and sealing small bag packing materials. The sachet packing machine has become an indispensable piece of equipment in modern production for food, medicine, chemicals, and other fields.

Features:

⦁ Microcomputer controlled;

⦁ Automated fast speed;

⦁ Multi-function integration.

Where Yuanyang excels

Yuanyang's unit integrates microcomputer control with modular filling options (auger or cup), enabling both fast throughput and dosing accuracy. The machine's multi-function integration (forming, filling, cutting, and sealing) makes it suitable for compact production lines targeting single-serve sachets for food and chemical samples.

Recommended applications

Recommended uses include instant beverage powder sachets, single-dose pharmaceuticals, agricultural seed samples, and small chemical reagent packs. Because of the microcomputer control, recipe switching and speed adjustments are straightforward for mixed-product runs.

Comparison table: Popular sachet packaging machines for powder

| Model / Type | Best for | Speed (sachets/min) | Filling tech | Key features |

|---|---|---|---|---|

| Yuanyang Sachet Packaging Machine | Small to medium powder sachets | 40–120 (format dependent) | Auger / volumetric | Microcomputer control, modular, multi-function integration |

| High-speed VFFS (Industrial) | High-volume consumer powders | 150–300+ | Multi-head auger/rotary | Servo control, inline checkweigher, high throughput |

| Premade Pouch Filler | Pre-printed barrier pouches | 30–100 | Pick-and-place auger/inkjet traceability | Gentle fill, high print quality support |

Regulatory and quality considerations

Food and pharmaceutical compliance

Packaging equipment used for consumables should support compliance with relevant regulations. For food safety systems, ISO 22000 is an international reference (ISO 22000). For pharmaceuticals, follow GMP guidelines such as those from the WHO (WHO GMP) and regional regulatory bodies like the U.S. FDA (21 CFR).

Traceability and serialization

Modern sachet packaging machines can be equipped with vision systems and printers for batch codes, expiry dates, and QR codes to support traceability and anti-counterfeiting. Integration with factory MES enables end-to-end production records for audits and recalls.

Validation and testing

Validate filling accuracy and seal integrity during commissioning. Use statistical sampling and checkweighers to maintain process control. For technical references on packaging machinery and reliability, general industry resources like the Packaging Machinery Manufacturers Institute and knowledge bases such as Wikipedia’s packaging machine overview can help provide context (Packaging machine — Wikipedia, Form-fill-seal machine — Wikipedia).

Practical tips for implementation and maintenance

Pilot runs and production trials

Before committing to a high-volume system, perform pilot runs with actual powder and pouch materials to validate filling accuracy, seal quality, and film compatibility. Pilot testing also reveals material handling issues such as bridging in hoppers or powder aeration.

Operator training and spare parts

Provide operator training on changeover, cleaning, and troubleshooting. Maintain critical spare parts (sealing bars, auger segments, cutters) to reduce downtime. A service contract with response SLAs will protect uptime in production-critical environments.

Environmental control

Control humidity and dust by using enclosed hoppers, filtered air inlets, or laminar flow booths for hygroscopic powders. Consider nitrogen flushing for oxygen-sensitive powders to extend shelf life and maintain product quality.

Buying guide & ROI considerations

Calculate total cost of ownership (TCO)

Beyond purchase price, include installation, training, spare parts, maintenance, and utilities when calculating ROI. Faster machines can reduce per-unit labor and packaging material waste but may require greater capital investment.

Scalability and future needs

Choose machines that can scale with your product line — modular designs and upgrade paths (e.g., moving from a single auger to multi-head systems) reduce future capital expenditures.

Supplier support and references

Request case studies, site references, and service support details from suppliers. Verify their experience with powders in your industry segment and ask for performance guarantees under your operating conditions.

FAQ

Q1: What is the difference between VFFS and premade pouch sachet machines?

A1: VFFS forms sachets from rollstock film on the machine, while premade pouch machines fill and seal pre-manufactured sachets. VFFS is often more economical for high volumes and flexible formats; premade pouch machines are chosen for complex printed/laminated pouches or when delicate handling is needed.

Q2: How do I choose between auger and volumetric fillers?

A2: Auger fillers offer high accuracy for fine powders and small doses. Volumetric cup fillers work well for larger dose sizes and coarser powders. For sticky or hygroscopic powders, consider positive displacement systems or environmental controls.

Q3: How important is microcomputer control on a sachet packaging machine?

A3: Microcomputer or PLC control improves repeatability, allows recipe storage, reduces downtime during format changes, and facilitates data logging for quality control — especially important in regulated sectors.

Q4: What certifications should packaging machines have for food and pharma?

A4: Machines should support compliance with GMP and relevant hygienic design standards; for food, ISO 22000 guidance is key, and for pharmaceuticals follow WHO GMP and local regulatory requirements (e.g., FDA 21 CFR). Ensure materials (food-grade stainless steel) and sanitary design features are documented.

Q5: Can Yuanyang sachet packaging machines handle different sachet sizes?

A5: Yes. The Yuanyang sachet packaging machine supports adjustable bag length and modular tooling so it can be reconfigured for a range of single-serve sachet sizes, with microcomputer control to save recipes for fast changeovers.

If you want to evaluate the best sachet packaging machine for your powder product, contact our sales team to request technical specs, pilot testing, and a quote. View the Sachet Packaging Machine for Sale or get in touch for a customized recommendation: Contact Sales / View Product.

What are the application scenarios of emulsifying equipment?

Top 10 drink powder mixer Manufacturers and Supplier Brands in France

Tips for buy filling and capping machines

Why choose YUANYANG as your food plate sealing machine supplier

Sachet Packaging Machine for Granules

Is the sachet packing machine equipped with a feeder also?

The standard quote is not included with a feeder, but we can add a feeder especially for the bag packaging machine if client need.

Single Layer Agitator Tank

Does the tank with mixer also has heater?

The model is non-heating type, the heating mixer tanks is another type with 3 layers, a heating jacket and an insulation jacket.

Homogenizing Mixer

Do you have temperature control system for the shampoo making machine?

Yes, there is temperature probe into tank at bottom. It detects temperature and display on the control panel. What’s more, the target temperature can be set.

FAQs

How do you ensure consistent product quality during production?

Our equipment features precision control systems that ensure stability and consistency at every stage of production. Automation reduces human error, guaranteeing consistent quality across each batch.

Liquid Soap Mixer Machine

Do you use brand parts for the mixing tank?

Yes, our we cooperate with core parts brand, such as Siemens motor, Beide motor, ABB motor, Delixi electricity, Schneider Electric, Delta frequency converter, Siemens PLC ,Mitsubishi touch screen, Mitsubishi frequency converter, German mechanical sealing, NSK bearing...

Yuany’s philosophy is quality first, service first, thus we get a good reputation in the market.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery