High Quality Bottle Capping Machines

# High-Quality Bottle Capping Machines for Seamless Production

Why Choose YUANYANG Capping Machines?

YUANYANG offers precision-engineered capping machines for bottles, designed to enhance efficiency and reliability in your production line. Our machines ensure airtight seals, reducing product waste and improving shelf life. With CE certification, we guarantee compliance with European safety standards, making us a trusted partner for global manufacturers.

Key Features of Our Bottle Capping Machines

1. Versatile Capping Solutions

Our capping machines accommodate various bottle types—glass, plastic, or PET—with adjustable torque settings for screw caps, snap caps, and press-on lids.

2. High-Speed Automation

Boost productivity with semi-automatic or fully automatic capping machines, achieving speeds of up to 200 bottles per minute. Ideal for food, pharmaceutical, and cosmetic industries.

3. Durable & Low-Maintenance Design

Constructed from stainless steel, our machines resist corrosion and wear, ensuring long-term performance with minimal downtime.

Industries We Serve

Pharmaceutical & Cosmetic Packaging

Ensure tamper-proof seals for medicines, creams, and lotions with GMP-compliant capping solutions.

Food & Beverage Production

From sauces to beverages, our machines deliver consistent, leak-proof seals to maintain product freshness.

YUANYANG’s Turnkey Support

Beyond capping machines, we provide complete production line integration, including filling, labeling, and coding equipment. Enjoy free technical training and lifetime customer support for hassle-free operations.

Upgrade your packaging line with YUANYANG’s reliable capping machines—contact us for a customized solution today!

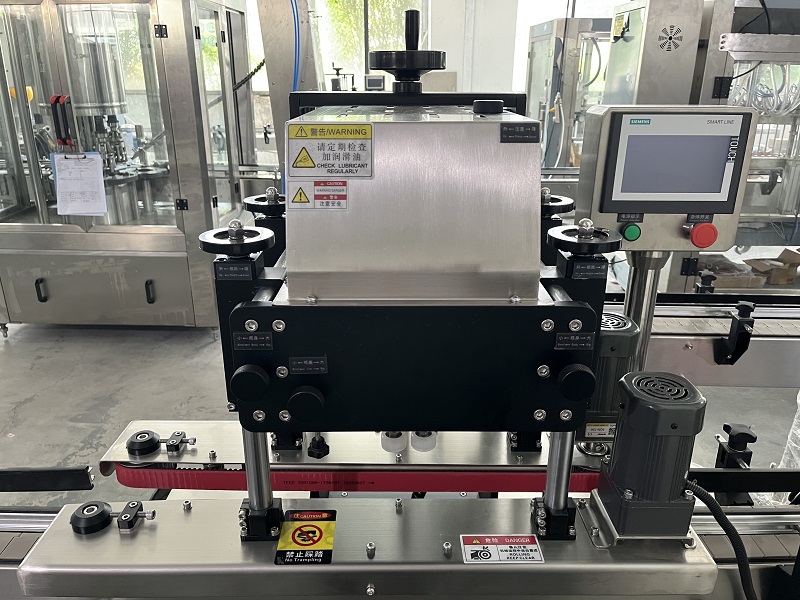

capping machine for bottles Display

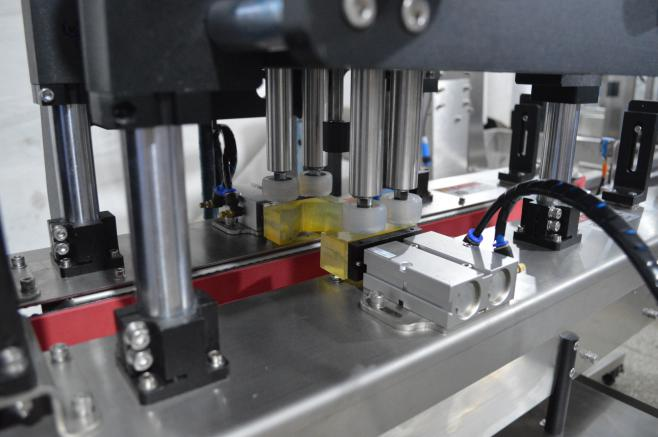

Is the servo capper be compatible for different bottle size and shapes?

Yes, the capping wheels can be adjusted higher or lower for different bottle height. The distance between wheels can be wider or closer for different cap diameter.

Do you have manual instructions for powder mixers?

Yes, we provide manual instruction of English version for clients as well as video test and operations for better understanding.

What’s the designed capacity and working capacity for the 500L hydraulic vacuum mixer?

The designed capacity is 540 liters, the working capacity is 500 liters.

Is the sachet packing machine equipped with a feeder also?

The standard quote is not included with a feeder, but we can add a feeder especially for the bag packaging machine if client need.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery