Discover YUANYANG Bead Homogenizers: Precision Solutions for Advanced Sample Preparation

Discover YUANYANG Bead Homogenizers: Precision Solutions for Advanced Sample Preparation

In the demanding world of scientific research, biotechnology, and material science, achieving precise and consistent sample homogenization is paramount. YUANYANG, a globally recognized leader in industrial mixers and agitators since 2008, extends its expertise to advanced laboratory and industrial applications with its state-of-the-art bead homogenizers. Designed for efficiency, reliability, and unparalleled performance, our bead homogenizers are critical tools for crucial processes.

What is a Bead Homogenizer?

A bead homogenizer is a specialized piece of equipment used to disrupt cells, tissues, or other biological samples, releasing their contents for further analysis or processing. This is achieved by vigorously agitating the sample with small beads, which mechanically shear and grind the material. Unlike traditional high shear mixers or emulsifying mixers that focus on liquid-liquid or liquid-powder blending, bead homogenizers are specifically engineered for effective cell lysis and homogenization of challenging solid or semi-solid samples, ensuring optimal sample preparation for downstream applications.

Why Choose YUANYANG Bead Homogenizers?

YUANYANG's bead homogenizers are engineered with our deep understanding of mixing technology and industrial mixer manufacturing excellence. Building on our reputation for vacuum homogenizers and high shear mixers, our bead homogenizers deliver:

- Superior Efficiency: Rapid and effective cell disruption, saving valuable time in your research or production workflow.

- Versatility: Capable of processing a wide range of sample types, from microorganisms to plant and animal tissues.

- Consistency & Reproducibility: Advanced control systems ensure consistent results batch after batch, crucial for sensitive applications.

- Durability & Reliability: Constructed from high-grade materials, reflecting the robust engineering found in all YUANYANG industrial mixers.

Applications of YUANYANG Bead Homogenizers

Our bead homogenizers are indispensable across numerous sectors:

- Biotechnology & Life Sciences: DNA/RNA extraction, protein isolation, enzyme analysis, and microbial cell lysis.

- Pharmaceuticals: Sample preparation for drug discovery, quality control, and formulation development.

- Food & Beverage: Pathogen detection and ingredient analysis.

- Environmental Analysis: Preparation of soil and water samples for contaminant detection.

- Cosmetics: Material preparation for research and development.

YUANYANG's Commitment to Your Success

At YUANYANG, our vision is to become the best industrial mixer and agitator manufacturer in the world. This commitment extends to every bead homogenizer we produce. We pride ourselves on providing complete production line equipment and comprehensive support. Since 2008, we've delivered not just machines, but complete solutions. Our offerings include:

- Free Technical Training: Empowering your team with the knowledge to operate our equipment effectively.

- One-Stop Installation Support: Seamless integration into your existing setup.

- Full Set of Turnkey Services: From consultation to post-installation support, ensuring a hassle-free experience.All our equipment, including bead homogenizers, adheres to stringent safety standards, evidenced by our multiple CE certifications.

For precise, efficient, and reliable sample homogenization, trust YUANYANG bead homogenizers. Partner with a manufacturer that has consistently delivered excellence in industrial mixing solutions since 2008. Explore how YUANYANG can elevate your processes at https://www.yuanymachinery.com/.

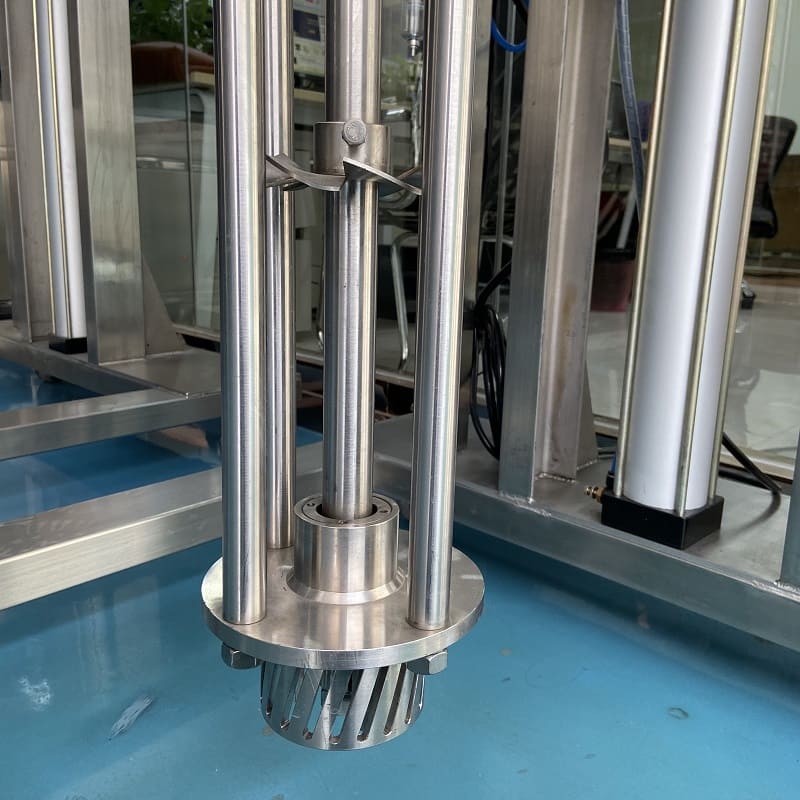

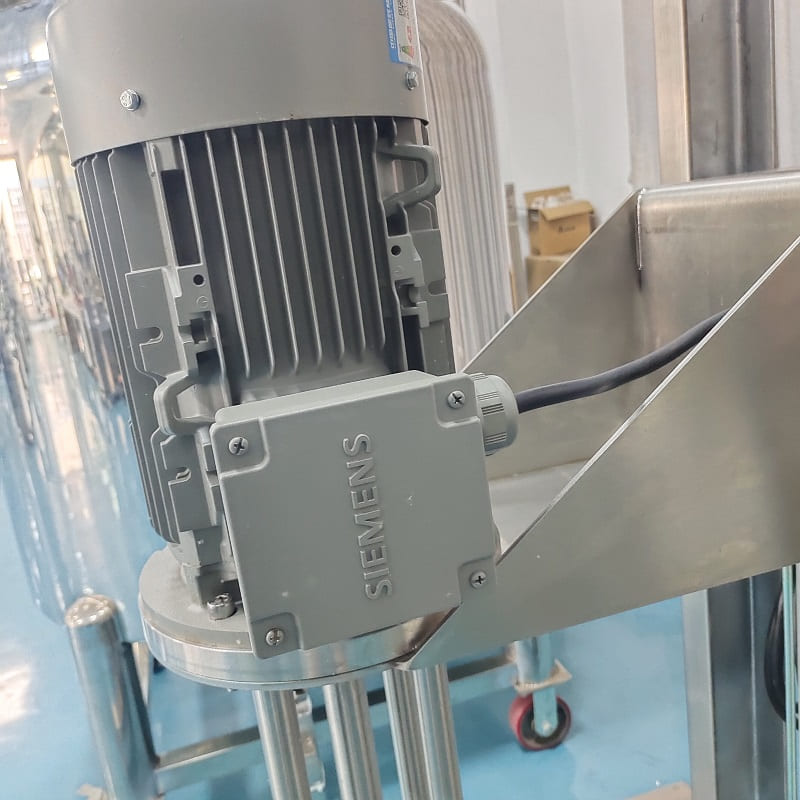

bead homogenizer Display

Do you have other types of labeling machine?

Yes, there are several types of labeling machine, including semi-automatic labeling machine, automatic labeling machine, round bottle labeling machine, flat labeling machine, double sides labeling machine, square bottle labeling machine.

Do your equipment meet GMP and other industry standards?

Yes. Our equipment fully complies with GMP, ISO, and other international industry standards and can be customized to meet specific regulatory requirements based on different markets and customers.

What’s the production time?

Normally, the production time of the high speed dispersing mixer is 10-15 days. It depends on manufacture’s order tightness.

Is the complete set with a conveyor for finished packages?

Yes, the standard auger packing machine is equipped with a conveyor to convey finished packages to other machines?

Automatic 4 Heads Detergent Filling Machine for Sale

Automatic 4 Heads Detergent Filling Machine for SaleUltimate Guide to Commercial Reverse Osmosis Systems 2026

This authoritative guide explores commercial reverse osmosis systems for 2026, covering working principles, cost analysis, maintenance protocols, and industrial applications. It addresses key questions on fluoride and microplastic removal, ensuring businesses make informed water treatment decisions.

Ultimate Storage Tank Guide for 2026: Selection & Innovations

A comprehensive guide for 2026 covering storage tank types, materials, API/EPA regulations, maintenance lifecycles, and future IoT trends. detailed insights for selecting the right tank, from small RO units to large industrial vessels.

Ultimate Guide to Filling Machine 2026 : Application & Selection

Select the perfect filling machine with YUANYANG. Get expert guidance, CE-certified quality, and full turnkey support.

Emulsion Mixer Mastery: Industrial High-Performance Use

Explore YUANYANG's CE-certified emulsion mixers for industrial use. Get turnkey support today!

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery