Mastering Corrosive Liquid Handling with YUANYANG Anti-Corrosion Liquid Filling Machines

Mastering Corrosive Liquid Handling with YUANYANG Anti-Corrosion Liquid Filling Machines

In industries where chemicals, acids, and other aggressive substances are processed, the safe and precise handling of liquids is paramount. Corrosive liquids pose significant challenges to conventional filling equipment, demanding specialized solutions that ensure both operational efficiency and long-term durability. YUANYANG, a leading manufacturer of industrial mixers and complete production line equipment since 2008, brings its extensive expertise to the forefront with its state-of-the-art Anti-Corrosion Liquid Filling Machines. Designed to withstand the harshest environments, our filling solutions are engineered for unparalleled reliability and precision.Why Specialized Anti-Corrosion Filling is Non-Negotiable

Handling corrosive liquids like strong acids, alkalis, or solvents requires more than just standard filling equipment. Without specialized design and materials, conventional machines can suffer rapid degradation, leading to costly breakdowns, product contamination, and severe safety risks. YUANYANG's Anti-Corrosion Liquid Filling Machines are built from the ground up with resistant materials such as high-grade plastics, PTFE, ceramics, or specific alloys, ensuring chemical compatibility and preventing corrosion. This specialized construction guarantees a longer lifespan for your equipment, reduces maintenance overheads, and safeguards your personnel and products.YUANYANG's Advanced Anti-Corrosion Filling Technology

Our Anti-Corrosion Liquid Filling Machines are at the cutting edge of industrial filling technology. Leveraging YUANYANG’s deep understanding of fluid dynamics and material science, these machines deliver exceptional accuracy and consistency, even with highly volatile or viscous corrosive substances. Key features include: precise dosing systems, robust anti-drip nozzles, and easy-to-clean designs that minimize cross-contamination risks. From small-batch pharmaceutical chemicals to large-volume industrial reagents, YUANYANG provides tailored solutions that optimize your production line's throughput while maintaining the highest safety standards.Complete Turnkey Solutions for Your Production Needs

Beyond standalone Anti-Corrosion Liquid Filling Machines, YUANYANG offers comprehensive support for your entire production ecosystem. As a provider of complete production line equipment, we seamlessly integrate our filling machines with other essential components like mixing equipment, storage tanks, capping machines, labeling machines, and inkjet printers. This holistic approach ensures compatibility and efficiency across your operation. Our commitment extends to providing free technical training and one-stop installation support, delivering a full set of turnkey services that minimize downtime and accelerate your path to productivity.Global Standards and Unwavering Quality Assurance

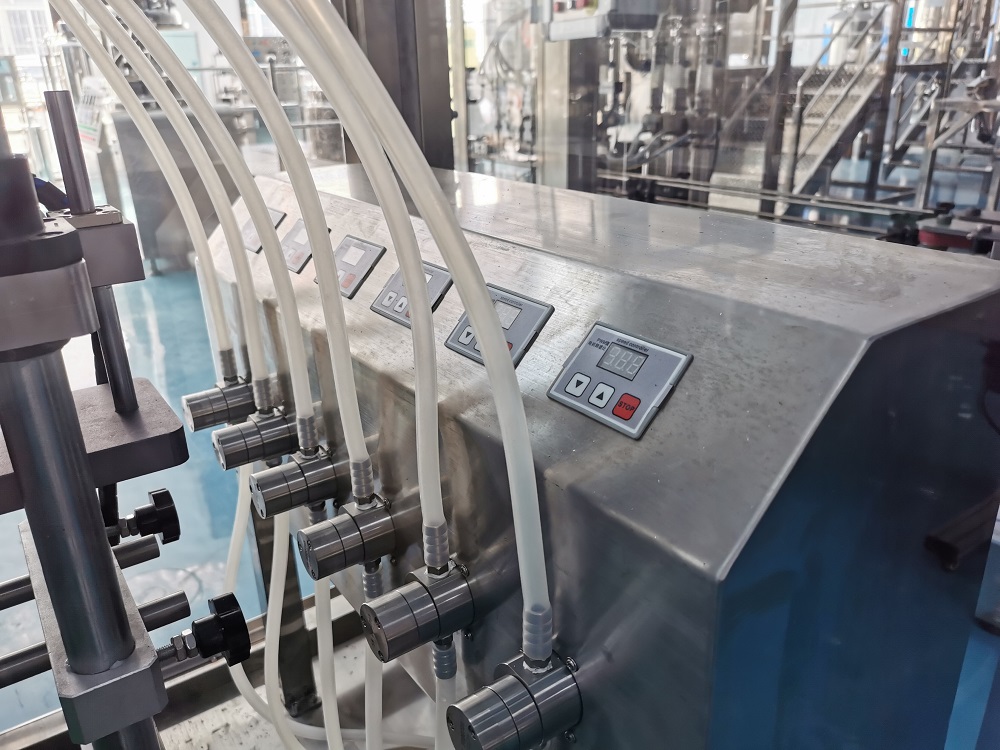

At YUANYANG, quality and safety are non-negotiable. Our dedication to excellence is underscored by multiple CE certifications, affirming our machines meet stringent European safety and health requirements. While CE marking signifies compliance, it also reflects our commitment to manufacturing equipment that adheres to global best practices. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and every Anti-Corrosion Liquid Filling Machine we produce is a testament to this unwavering pursuit of superior quality and performance. Partner with YUANYANG for durable, precise, and safe solutions for all your corrosive liquid filling challenges.Anti-Corrosion Liquid Filling Machine Display

When shall we choose electric heating or steam heating?

The electric heating is with bottom electric tubes, the cost is lower compared with steam heating, which requires a steam generator and needs steam pipes. So we recommend small business choose electric heating for small capacity.

What’s the guarantee if we purchase from you?

All the equipment ordered from us will be provided with 2 years guarantee from the delivery date. If there is any wearing part broken within the warranty and isn’t caused by improper operation, we would offer the new parts for free.

Is there any handle for easy movement?

Yes, there is handle for each steel tank.

What capacity do you provide for vacuum emulsifying mixer machine?

We can supply from 50 Liters to 5000 Liters for mixing tanks,but we recommend maximum 1000L for vacuum emulsifier homogenizer,whose the package sizes is just ok for regular 40” HQ container.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery