Throughput Optimization: Selecting High-Speed Tube Sealers

- Throughput Optimization: Selecting High-Speed Tube Sealers

- Why throughput matters for your sealing machine selection

- Key performance metrics to evaluate in a sealing machine

- Trade-offs: Speed versus quality in high-speed tube sealers

- Automatic Tube Sealing Machine for Sale — Product overview

- How the Yuanyang Automatic Tube Sealing Machine addresses throughput optimization

- Material compatibility and sealing machine selection

- Practical throughput comparison: sealing machines at-a-glance

- Integration and line balancing with your sealing machine

- Maintenance, uptime and operator training

- Regulatory and quality considerations when selecting a sealing machine

- ROI calculation: how to justify investment in a high-speed sealing machine

- Case scenarios: selecting the sealing machine by industry

- Selection checklist before buying an Automatic Tube Sealing Machine for Sale

- Why choose Yuanyang — brand advantages for throughput-focused buyers

- Frequently Asked Questions (FAQ)

- Q1: What is the realistic speed I can expect from a high-speed tube sealing machine?

- Q2: Can the same sealing machine handle both aluminum and plastic tubes?

- Q3: How do I validate seal integrity on a production line?

- Q4: What maintenance schedule keeps a high-speed sealer reliable?

- Q5: Is operator training included when purchasing an Automatic Tube Sealing Machine for Sale?

- Contact and next steps — view product or request a demo

- Authoritative references and further reading

Throughput Optimization: Selecting High-Speed Tube Sealers

Why throughput matters for your sealing machine selection

Throughput is a core driver of profitability and competitiveness in industries that use tubes for packaging — cosmetics, food, pharmaceuticals, and chemicals. A high-speed sealing machine can increase output, reduce per-unit labor cost, and improve consistency, but choosing the wrong equipment can introduce bottlenecks, quality failures, or regulatory risk. This guide explains how to evaluate sealing machine options, with a focus on selecting a high-speed tube sealer that balances speed, accuracy, and operational reliability. Finally, all these considerations connect back to the buying guide for automatic tube sealing machines for industrial use, ensuring a full-circle approach from selection, specification evaluation, procurement, cost optimization, integration, material compatibility, compliance, and throughput performance.

Key performance metrics to evaluate in a sealing machine

When optimizing throughput, focus on measurable machine characteristics. These metrics help you quantify performance and compare models meaningfully:

- Speed (tubes per minute): Maximum and practical sustained speed under your product conditions.

- Filling accuracy (% deviation): Determines waste and rework — critical for regulated products.

- Seal integrity (leak rate / pass rate): Measured by visual inspection, pressure or vacuum tests.

- Changeover time (min): How long to switch sizes/formulations — impacts effective throughput.

- Downtime and maintenance intervals (MTTR/MTBF): Affects overall equipment effectiveness (OEE).

- Footprint and integration capability: Physical compatibility with existing lines and conveyors.

Trade-offs: Speed versus quality in high-speed tube sealers

Higher speed on a sealing machine often increases stress on filling and sealing subsystems. Rapid cycles can amplify small variances in tube positioning, filler timing or adhesive behavior, producing poor seals or cosmetic defects. To select the right sealing machine, you must evaluate whether the claimed top speed is sustainable for your tube material, product viscosity, and regulatory verification methods.

Decisions should be based on practical throughput (sustained running speed) rather than marketing peak speed. Practical throughput equals theoretical speed adjusted for changeovers, rejects, maintenance and quality checks. For many plants, reducing peak speed by 10–20% yields better overall throughput due to fewer interruptions and lower scrap.

Automatic Tube Sealing Machine for Sale — Product overview

Below is a concise introduction to a practical option when seeking a high-performance sealing machine for medium- to high-volume production.

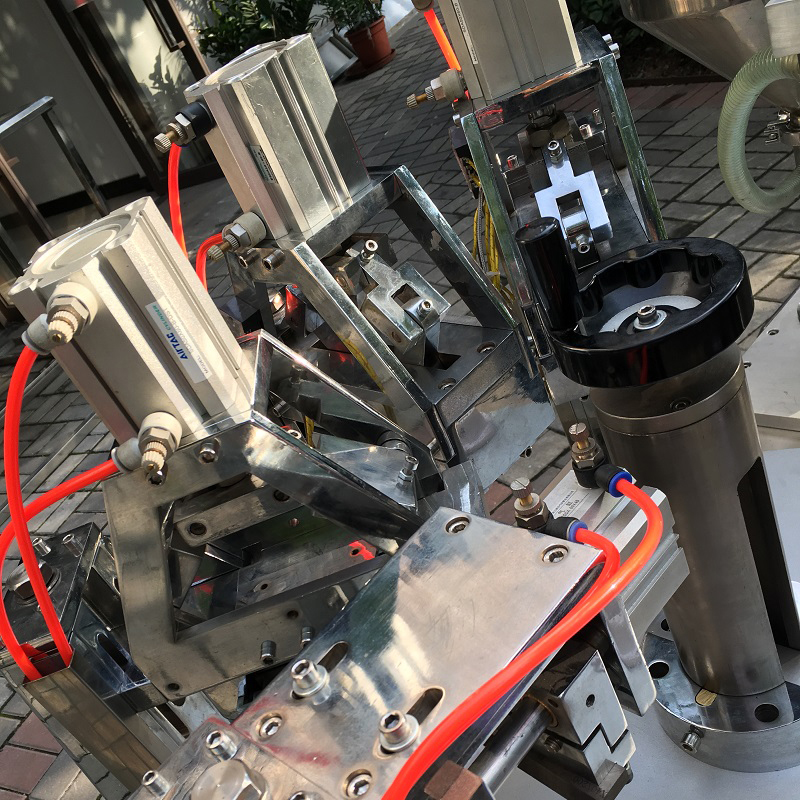

Yuanyang automatic tube sealing machine is an integrated automatic packaging machine with filling and sealing for aluminum or plastic tubes. The tube packing machine has become an indispensable piece of equipment in modern production for cosmetic, food, medicine, chemical, and other fields.

Features:

⦁ Touchscreen operation, humanized design, simple and intuitive.

⦁ Pneumatic filling control to ensure the accuracy of filling.

⦁ Photoelectric sensing and pneumatic linkage control.

⦁ Pneumatic control valve, efficient and safe. The runner can be adjusted and cleaned separately.

How the Yuanyang Automatic Tube Sealing Machine addresses throughput optimization

This integrated filling-and-sealing design reduces internal line transfers, which are common sources of bottlenecks. Key throughput benefits include:

- Integrated filling and sealing: eliminates timing mismatches between separate fillers and sealers.

- Touchscreen controls: faster parameter recall for quick changeovers and recipe management.

- Pneumatic filling control and photoelectric sensing: improve repeatability at higher speeds.

- Modular runner and cleaning features: reduce downtime for sanitation in regulated industries.

Material compatibility and sealing machine selection

Sealing behavior depends heavily on tube materials and coatings. Typical tube materials include laminated aluminum, pure aluminum, polyethylene (PE), polypropylene (PP), and co-extruded laminates. Each behaves differently under heat, pressure, or induction sealing. Selecting a sealing machine means matching the sealing method (crimp + heat, induction, ultrasonic, or adhesive-seal) to the tube material and the product’s shelf-life and sterility needs.

Work with material suppliers to run sample trials. A machine’s top speed is only useful if the tube and product can sustain that processing stress without deformation, leakage, or seal delamination.

Practical throughput comparison: sealing machines at-a-glance

The following comparison gives a realistic view of typical machine capabilities. Use it as a starting point for vendor conversations and trial planning.

| Model / Type | Speed (tubes/min) | Filling Accuracy | Changeover Time | Typical Footprint | Price Range (typical) |

|---|---|---|---|---|---|

| Integrated high-speed (e.g., Yuanyang-style) | 50–180 | ±0.5%–1.5% | 10–30 min | Compact – 1.5–3 m² | $30k–$120k |

| Dedicated high-speed sealer (inline) | 100–300 | ±1%–3% | 20–45 min | 2–4 m² | $50k–$200k |

| Laboratory/low-speed sealer | 5–40 | ±0.2%–1% | 5–15 min | <1–2 m² | $8k–$35k |

Notes: Numbers are indicative ranges. Actual results depend on tube design, product viscosity, and operator practices.

Integration and line balancing with your sealing machine

To achieve optimized throughput you must balance the tube sealer with upstream and downstream equipment: tube collators, printers/inkjet coders, conveyors, inspection stations, and case packers. Mistakes in integration cause starvation or accumulation of WIP (work-in-progress), lowering OEE.

Key integration steps:

- Assess conveyor speed compatibility and buffer capacity.

- Synchronize machine controls via standard industrial interfaces (PLC, fieldbus, I/O).

- Implement inspection inline (vision or leak detection) with rejection downstream to prevent blockages.

- Plan for cleaning-in-place (CIP) or quick disassembly to minimize cleaning downtime for food, cosmetics, and pharmaceuticals.

Maintenance, uptime and operator training

High-speed machines demand proactive maintenance. Preventive schedules and operator training reduce mean time to repair (MTTR) and keep the line running near design throughput. A typical maintenance program includes daily checks (sensors, nozzles), weekly lubrication and pneumatic checks, and monthly seal head inspection.

Invest in training programs and standard operating procedures (SOPs). Skilled operators can reduce changeover time and quickly diagnose issues that would otherwise cause long stops.

Regulatory and quality considerations when selecting a sealing machine

For pharmaceutical, medical, and food products, regulatory compliance affects machine selection. Consider:

- Materials of construction and cleanability for GMP compliance.

- Traceability features (electronic batch logs, serial numbers, printer/inkjet integration).

- Validation and qualification protocols (IQ/OQ/PQ) for equipment used in regulated production.

Machines that simplify validation (e.g., with built-in data logging and recipe management) reduce time-to-market and compliance overhead.

ROI calculation: how to justify investment in a high-speed sealing machine

Calculate ROI using a realistic throughput estimate (practical throughput), factoring in labor savings, reduction in rejects, and increased capacity. Example elements for ROI model:

- Incremental output (additional tubes per shift) × gross margin per unit = incremental gross profit.

- Operational savings: labor hours reduced, decreased rework and scrap rates.

- Capital cost, installation, training, and validation cost.

- Payback period and internal rate of return (IRR) over expected machine lifetime.

Typical payback periods for integrated high-speed tube sealers range from 12 to 36 months depending on volumes and yield improvements.

Case scenarios: selecting the sealing machine by industry

Different industries emphasize different attributes:

- Cosmetics: appearance and accurate fill volumes; look for sanitary design and high cosmetic finish.

- Food: hygiene, CIP capability, and materials compatibility for edible products.

- Pharmaceuticals: traceability, validation support, and minimal dead volume in fillers.

- Chemicals: robust sealing for viscous or aggressive formulations and durable materials.

Selection checklist before buying an Automatic Tube Sealing Machine for Sale

Use this checklist during vendor evaluation and trials:

- Request sample runs with your exact tubes and product.

- Verify sustained practical throughput under production conditions.

- Check filling accuracy and seal integrity test results.

- Assess changeover steps and time with actual operators.

- Confirm spare parts availability and recommended maintenance schedule.

- Review compliance support for your industry (IQ/OQ/PQ documentation).

- Confirm warranty, training, and after-sales service terms.

Why choose Yuanyang — brand advantages for throughput-focused buyers

Yuanyang’s Automatic Tube Sealing Machine for Sale offers a compact integrated design that targets throughput and consistency for medium- and high-volume lines. Brand advantages include touchscreen recipe management, pneumatic filling control for accuracy, and photoelectric sensing to maintain positioning at speed. The machine’s modular runner and separate-clean features are practical for industries that need frequent cleaning or rapid material changeovers.

Frequently Asked Questions (FAQ)

Q1: What is the realistic speed I can expect from a high-speed tube sealing machine?

A: Realistic or practical speed usually falls 10–30% below the machine’s peak-rated speed due to changeovers, quality checks and unavoidable downtime. For integrated machines like Yuanyang, practical speeds between 50–150 tubes/min are common depending on tube size and product viscosity.

Q2: Can the same sealing machine handle both aluminum and plastic tubes?

A: Many integrated machines can handle both, but you must confirm sealing method compatibility (e.g., crimping, heat seal, induction, ultrasonic). Material-specific adjustments, tooling changes or auxiliary systems may be required.

Q3: How do I validate seal integrity on a production line?

A: Use a combination of visual inspection, random destructive testing (burst/leak tests), and non-destructive methods (vacuum/pressure decay or helium leak testing for high-integrity requirements). Inline vision inspection and automated leak detection reduce manual QC burden.

Q4: What maintenance schedule keeps a high-speed sealer reliable?

A: Daily checks of sensors and nozzles, weekly pneumatic and lubrication checks, and monthly seal head inspections are common. Follow vendor recommendations for intervals and part replacements.

Q5: Is operator training included when purchasing an Automatic Tube Sealing Machine for Sale?

A: Many reputable suppliers include basic operator training and startup support. Verify training scope (operators, maintenance staff, and validation engineers) and whether additional training packages are available.

Contact and next steps — view product or request a demo

If you’re ready to evaluate an Automatic Tube Sealing Machine for Sale or want a live demonstration of throughput with your tubes and product, contact our sales team. We provide factory trials, performance data capture, and support with ROI calculations and regulatory documentation. Reach out for a quote, sample run, or to schedule an on-site or virtual demonstration.

Authoritative references and further reading

For additional technical background and regulatory information, consult the following authoritative resources:

- Packaging machine — Wikipedia: https://en.wikipedia.org/wiki/Packaging_machine

- Tube (container) — Wikipedia: https://en.wikipedia.org/wiki/Tube_(container)

- PMMI (Packaging Machinery Manufacturers Institute): https://www.pmmi.org/

- U.S. Food and Drug Administration (FDA) — Cosmetics: https://www.fda.gov/cosmetics

- World Health Organization (WHO) — Good Manufacturing Practices: https://www.who.int/teams/regulation-prequalification/regulation-and-safety/quality-assurance/gmp

We recommend running a production trial with sample materials to validate throughput claims before committing to purchase. For hands-on support, contact our team to discuss requirements and arrange live trials or data-based comparisons.

Hygienic Design Features of Stainless Steel Mixing Tanks

Wholesale automatic spindle capping machine manufacturer and supplier in Asia

Custom cosmetic emulsion mixing equipment Manufacturers and Suppliers in Asia

How to Choose Right continuous powder mixer manufacturer and supplier in America?

Industries

Do you provide operational training?

Yes, we provide detailed operational manuals and comprehensive training to ensure safe and efficient operation of the equipment.

Powder Sachet Packaging Machine

Is the complete set with a conveyor for finished packages?

Yes, the standard auger packing machine is equipped with a conveyor to convey finished packages to other machines?

Portable Storage Tank

Can you add a lid for the storage tank?

Yes, the lid can be added and customized. For example, with a central hole for overhead mixer, with a material hopper for adding powder or liquids.

FAQs

Can your equipment produce multiple types of products?

Our equipment is flexible and suitable for producing a wide range of products. You can use the same equipment to produce various products such as creams, lotions, liquid soaps, shampoos, etc., while maintaining high efficiency during product switching.

Detergent powder mixer

Can you add load cell for material weighing for the ribbon mixer machine?

Yes, load cell is an optional choice. It is usually installed on feet. And there will be indicator on the control panel.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for Sale

Yuanyang automatic screw capping machine is a kind of four-wheel bottle capping machine. The automatic screw capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Full pneumatic drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Automatic Metal Caps Capping Machine for Sale

Yuanyang automatic metal cap capping machine is a bottle capper for bottles with metal caps, which is often used to close lids of containers such as bottles and jars. The glass bottle metal capping machine is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for glass bottles with metal caps.

Automatic Pump Head Feeding and Capping Machine for Sale

Yuanyang automatic pump head feeding and capping machine is a bottle cap sorter and capper for bottles with pump heads, which is often used to close lids of containers such as nail polish, sprayers, and shampoo. The capping machine with a pump head feeder is widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production line .

Features:

⦁ Pneumatic and electric drive;

⦁ Automated fast speed;

⦁ Suitable for various types of caps.

Automatic High Speed Capping Machine for Sale

The Yuanyang automatic high-speed capping machine is a kind of 8-wheel bottle-capping machine with fast working efficiency. The automatic capper is often used to close lids of containers such as bottles and jars, especially for plastic bottles, which are widely used in food, medicine, chemical, cosmetic, and other industries for mass production and continuous production lines.

Features:

⦁ Electric drive;

⦁ Automated fast speed;

⦁ Suitable for various screw caps, pumps, and spray bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery