YUANYANG Homogenizer Mixers for Cosmetics | Achieve Flawless Formulations

Elevate Your Cosmetic Formulations with YUANYANG Homogenizer Mixers

In the competitive world of cosmetics, achieving impeccable product quality, consistent texture, and long-lasting stability is paramount. YUANYANG, a leading manufacturer of industrial mixers and agitators in China since 2008, understands these critical demands. We specialize in providing state-of-the-art homogenizer mixer for cosmetics, engineered to transform your raw ingredients into perfect, market-ready products. With YUANYANG, you’re not just buying equipment; you’re investing in precision, efficiency, and a partner dedicated to your success.

The Critical Role of Homogenization in Cosmetics

The secret to many successful cosmetic products lies in their formulation's homogeneity. Whether it’s a luxurious cream, a silky lotion, a stable serum, or a vibrant foundation, effective mixing and homogenization are essential. A high-quality cosmetic homogenizer ensures that all ingredients, including oils, water, active compounds, and pigments, are uniformly dispersed and emulsified. This process prevents separation, enhances absorption, improves sensory feel, extends shelf life, and ly delivers the consistent, high-performance product consumers expect. Without proper homogenization, your cosmetic products risk instability, poor aesthetics, and reduced efficacy, directly impacting brand reputation and consumer satisfaction.

YUANYANG's Advanced Homogenizer Mixers for Cosmetics

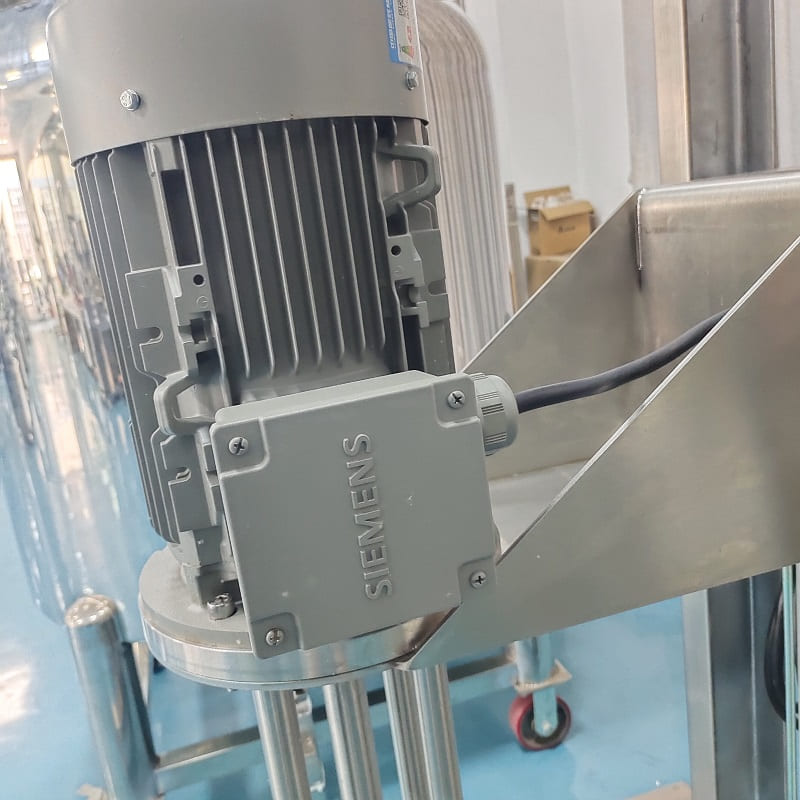

YUANYANG offers a comprehensive range of sophisticated mixing solutions tailored for the cosmetic industry. Our flagship products include advanced vacuum homogenizers, powerful vacuum emulsifying mixers, and efficient high shear mixers. Each machine is designed for unparalleled performance, ensuring ultra-fine particle size reduction and superior emulsification. Our vacuum systems protect sensitive ingredients from oxidation and contamination, while precise temperature control and robust construction guarantee optimal processing conditions. From pilot scale to industrial production, YUANYANG’s cosmetic mixers handle a diverse array of viscosities and batch sizes, consistently delivering homogeneous, stable, and visually appealing cosmetic formulations.

Tailored Solutions for Complete Cosmetic Production Lines

At YUANYANG, we go beyond individual machines. Since 2008, we have focused on providing complete production line equipment, offering a seamless integration of all necessary machinery. Beyond our core mixing equipment, our portfolio includes essential components such as storage tanks, filling machines, capping machines, labeling machines, sealing machines, inkjet printers, and water treatment equipment. We pride ourselves on offering comprehensive support, including free technical training and one-stop installation support, delivering a full set of turnkey services. This holistic approach ensures efficiency, reduces operational complexities, and accelerates your time to market.

Why Choose YUANYANG for Your Cosmetic Mixing Needs?

Choosing YUANYANG means partnering with a recognized leader in industrial mixing technology. We are committed to engineering excellence, backed by multiple CE certifications, which signify our adherence to stringent EU safety and health standards. Our vision is clear: to become the best industrial mixer and agitator manufacturer in the world. With YUANYANG, you gain access to cutting-edge technology, expert consultation, reliable equipment, and unparalleled after-sales support. Let us help you achieve superior product quality and operational efficiency. Visit yuanymachinery.com to explore our solutions and elevate your cosmetic production.

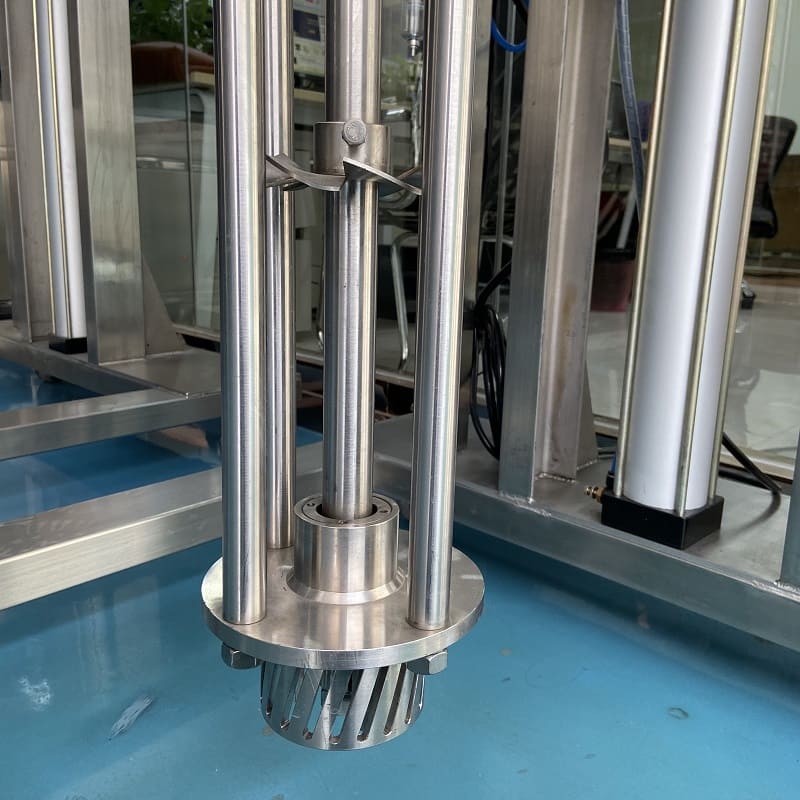

homogenizer mixer for cosmetics Display

Does Yuanyang's equipment meet food hygiene standards?

Yes, all our equipment is made with materials that comply with food hygiene standards, ensuring the parts in contact with food are hygienic and prevent contamination.

Does Yuanyang’s pharmaceutical equipment comply with GMP standards?

Yes, all of Yuanyang’s pharmaceutical equipment complies with Good Manufacturing Practice (GMP) standards, ensuring quality and hygiene at every production stage, meeting the requirements of global pharmaceutical regulatory agencies.

Can it fill the paste like dough?

No, the dough is too viscous and can’t flow down. The materials must be easy to flow down for this vertical filling machine. And for too viscous paste, pressure filling machine or heating mixing filling machine will be recommended based on materials.

How does the automatic bottle sealing machine work?

Electromagnetic induction sealing machine uses high-frequency electromagnetic field to act on the packaging film, resulting in an induced current inside, which will generate heat, melt the packaging film, and then form a sealing after cooling.

Is the height of the bottle cap sealing machine adjustable?

Yes, there is a handle wheel to adjust the height of sealing head according to different bottle height.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery