3 Tips to Get A Quick Quote from Supplier

Have a general understanding about the reasons why the suppliers tend to ask a list of questions about liquid detergent mixers, you will know how to get a quick quote from the supplier.

- Why can't you get a quick quote for a liquid detergent mixer?

- ❗ 1. Wide Range of Customization for liquid detergent mixing tank

- ❗ 2. Your Product Characteristics Matter

- ❗ 3. Accurate Quote = No Hidden Costs Later

- ✅ Our Goal: The Right Machine at the Right Price

- ✅ 3 Tips to Get a Quick Quotation from a Supplier:

-

Why can't you get a quick quote for a liquid detergent mixer?

- As a buyer, you may often wonder, I just want to know the price, but why does the supplier tend to ask me so many questions, which takes plenty of time before I know the price?

- Are you bored of the following questions?

They often ask:

1. What capacity do you need?

- 2. Do you need heating: steam heating or electric heating?

- 3. Do you need homogenizing?

- 4. What types of mixing do you want?

- 5. What products do you produce?

As the suppliers, they also want to send you a quote immediately; they understand that you may wish to receive a quick price estimate.

However, to ensure the buyer gets a realistic and accurate quotation, it is necessary for the supplier to first confirm a few technical details about your requirements.

Here’s why an immediate price is not provided without full specifications:

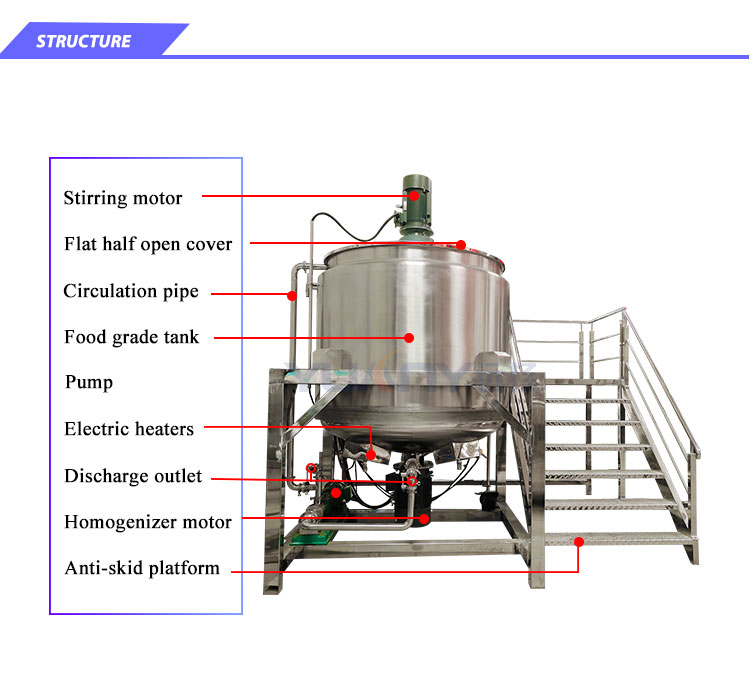

❗ 1. Wide Range of Customization for liquid detergent mixing tank

Mixing tanks are not one-size-fits-all equipment. The final cost can vary significantly based on:

-

Tank capacity (e.g. 100L vs 2000L)

-

Material construction (304 vs 316L stainless steel)

-

Mixing type (simple paddle vs high-shear emulsifier)

-

Additional features (heating, cooling, vacuum, control systems, metering, weighing, pump)

A 500L simple tank without heating costs far less than a 200L vacuum emulsifying tank with PLC and steam heating.

❗ 2. Your Product Characteristics Matter

To design the proper structure and choose the right motor, mixer, and sealing method, the suppliers need to understand:

-

The viscosity and nature of your material (water-like, creamy, sticky, etc.)

-

Whether vacuum deaeration or temperature control is required

-

Any chemical compatibility concerns (acid/alkaline/corrosive materials)

❗ 3. Accurate Quote = No Hidden Costs Later

Providing a quote without clear requirements may result in

-

An underestimated price that later increases due to missing functions

-

Or an over-engineered system that exceeds your actual needs and budget

✅ Our Goal: The Right Machine at the Right Price

The supplier tend to ask you a few questions; the purpose is to get a machine that fits your product and production line

-

Help you to avoid costly design changes or delays after order confirmation or purchase the wrong machines.

-

✅ 3 Tips to Get a Quick Quotation from a Supplier:

- 1. Have a clear requirement about capacity.

2. Directly tell the supplier of the function or configuration that you need.

Have the basic knowledge of your product formula and the function you need, and tell the suppliers.

If you have no idea about this equipment, please tell the supplier a general plan; the supplier will recommend a suitable solution for you.

3. Tell the supplier what products you produce and your budget if you have one.

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Open Lid Storage Tank

Is the material of the cosmetic tank anti-corrosive?

Yes, the tank is made of stainless steel 304 or 316L, it can store corrosive chemicals. But it is recommend to use PP storage tank if the liquid is strong acid, alkali and corrosive chemical liquid

Semi Automatic Double Sides Labeling Machine

What types bottles are suitable for this label dispenser?

It is suitable for single side and double side labeling of flat bottles, round bottles and square bottles, such as shampoo, laundry detergent flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other double side labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

Cosmetic

Can your equipment integrate with existing production lines?

Yes. Our equipment can seamlessly integrate with your existing production lines, ensuring smooth operation without disruptions.

Cosmetic Making Machine

How does water phase and oil phase materials get into the main homogenizer mixer tank?

The cosmetic mixing machine is designed vacuum feeding system. The water and oil pots can be automatically sucked into main emulsifying mixer pot under vacuum condition by conveying pipes to ensure materials are protected from external contamination.

Sachet Packaging Machine

What’s the weight range can the automatic liquid packing machine pack?

Filling weight of this auto plastic packing machine should be less than 100g for this model. There will be different model for 100-500g or 500-1000g.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery