Best Industrial Mixer Manufacturers: Top 10 Reliable Suppliers

Discover the Best Industrial Mixer Manufacturers with YUANYANG. Explore our list of the top 10 reliable suppliers for high-quality industrial mixers, ensuring efficiency and durability for your business needs. Choose proven industry leaders today!

- What Makes a Reliable Industrial Mixer Manufacturer?

- Key Factors to Consider When Choosing an Industrial Mixer Manufacturer

- Top 10 Best Industrial Mixer Manufacturers in 2025

- Industrial Mixer Applications: Which Manufacturer Fits Your Needs?

- Where to Buy from the Best Industrial Mixer Manufacturers

- Conclusion

What Makes a Reliable Industrial Mixer Manufacturer?

Choosing the right industrial mixer manufacturer is an important decision that has a major effect on performance, product quality, and operation efficiency in industries such as cosmetics, chemicals, food, and pharmaceuticals. A reliable manufacturer provides solutions other than just supplying machinery. Manufacturers are concerned with providing solutions that are carefully engineered with the complexities of your process, materials used, and the stringent requirements for safety and hygiene. A history of years in industry, proven by many successful project results, along with access to state of the art mixing technologies, strengthens a manufacturer’s reputation for reliability. Moreover, these manufacturers do not only provide equipment but also provide process review, equipment recommendation, turnkey commissioning, staff training, and after-sales service which ensures long term system performance.

Quality and innovation are the pillars of differentiating a reliable manufacturer from others. Manufacturers of this kind of reliability will make sure their in-house quality assurance processes are strict, certified to meet global standards like GMP, FDA or CE and can adopt sophisticated automation and CIP technologies. Customisation is pivotal: You can count on such a manufacturer to take their time to carefully evaluate your process, whether it is high-viscosity products or fragile emulsions, and offer the best mixing technology for your application. Reliability requires a customised approach to every application; Trust is built upon proven knowledge, quick communication, and the presentation of reliable product results over time.

Key Factors to Consider When Choosing an Industrial Mixer Manufacturer

In order to make informed decisions about industrial mixers, stakeholders should review several basic aspects that measure overall effectiveness, efficiency, and return on investment. First, evaluate the manufacturer's specialization. Secondly, evaluate their engineering and customisation capabilities. Are the manufacturer’s able to customise mixer configuration, tank design and control systems to suit your batch size, viscosity range or application requirements? Pharmaceutical mixing usually requires careful, sterile systems which are rigorously validated, whereas food processing often requires automatic cleaning in place (CIP) and gentle mixer designs to protect ingredient consistency. A growing array of solutions like high-shear emulsifying devices, inline mixers, vacuum homogenizers, and powder mixers should meet your operational needs.

Secondly, think of how easy it is for the manufacturer to engineer and tailor their equipment. choice It is also important to assess the company’s after sales service and spare parts stock – an important aspect which can help eliminate unplanned downtime. Choose manufacturers who take care of everything in your process, from YUANYANG’s holistic approach that includes global technical support and smooth integration of a production line. One of the important steps would be to check their client roster and collected testimonials to determine their position in the industry. Firsthand accounts of clients, industry accreditations, and on-site experience are critical assurances of the expertise of a manufacturer and scalability and dependability of their mixing products.

Top 10 Best Industrial Mixer Manufacturers in 2025

With the demand for accurate industrial mixing technologies increasing across the world, the choice of key players in the market becomes more important. The following is a list of the top 10 companies in 2025, selected because their product quality is excellent, their designs are innovative, and their engineering approaches are client-oriented.

- 1. YUANYANG (China)

- Main Products: Vacuum homogenizing emulsifying mixers; homogenizing mixers; liquid mixing tanks; lifting mixers; storage tanks; automatic filling, capping, labeling & sealing machines; powder production lines; RO water treatment.

- Advantages: YUANYANG is the expert in complete mixing and production-line solutions for different needs. Its expertise focuses on bespoke designs that are specific to the exact specifications of cosmetic, chemical, food and pharmaceutical processes ensuring maximum efficiency and smooth cleaning. Closely monitored internal quality controls and robust engineering design guarantee high performance in every batch. Our wide range of services, such as process advice, operator training, and ongoing maintenance support ensure that every installation operates optimally. YUANYANG’s open pricing model and simplified supply chain processes are both fast delivery and substantial savings on long-term expenditures. Due to its long-standing record of reliability and honesty, confirmed by international client testimonials, YUANYANG is considered a worthy supplier of high-quality, thorough mixing solutions.

-

- 2. GEA Group (Germany)

Main Products: High-shear mixers; paddle & ribbon blenders; vacuum dryers; spray granulators.

Advantages: GEA is known globally for its customized, sanitary mixing technology that is appropriate for food, dairy, and pharmaceutical manufacturers. GEA’s mixers offer secure, contamination-free production with hygienic designs and compatibility for CIP/SIP. GEA is a specialist in the unification of state-of-the-art automation technologies, energy savings, and complete global service after the sale. GEA’s dedication to engineering excellence and customized system development helps manufacturers to consistently meet high quality requirements and achieve the best production results.

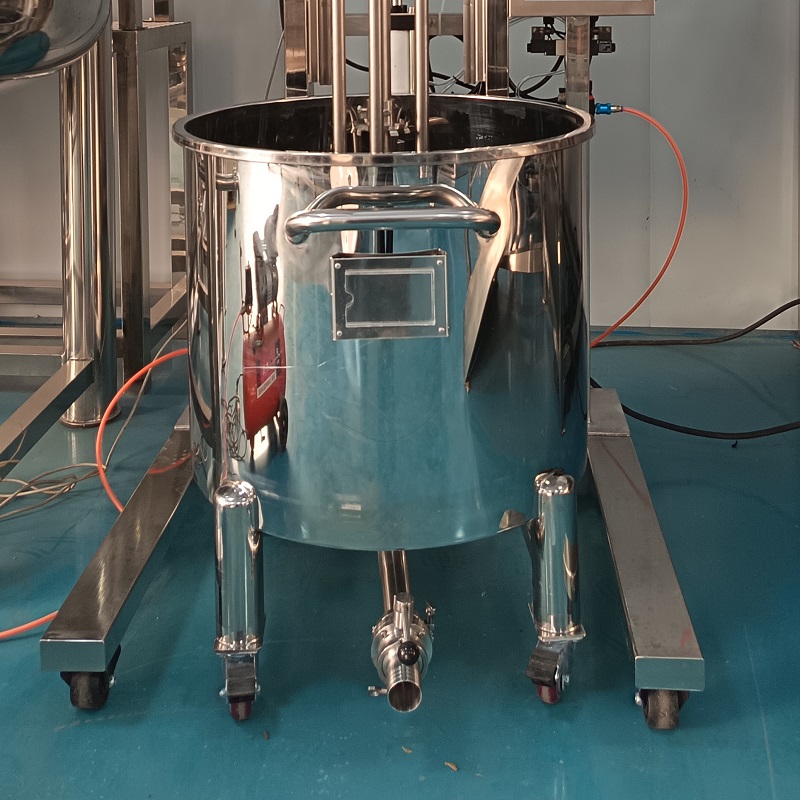

- 3. SPX FLOW (USA)

Main Products: High-viscosity mixers; rotor-stator mixers; scrape-surface heat exchangers.

Advantages: SPX FLOW is a specialist in advanced mixing solutions for challenging food, beverage, pharmaceutical, and chemical processes. SPX FLOW’s mixers provide precision with rotor-stators, integrated advanced control systems, and CIP (Clean-in-Place) support. By its strong R&D, SPX offers innovative technologies aimed at speeding up production, reducing waste and guaranteeing superior hygiene. Due to their wide global reach, they provide reliable support and flexible solutions to meet the customers’ needs.

- 4. Charles Ross & Son Company (USA)

Main Products: Planetary mixers; dual-shaft mixers; vacuum tumble blenders.

Advantages: For more than 170 years, Ross has been leading the way in the supply of mixing solutions, with products such as planetary and dual-shaft mixers. Ross’s machines are designed to handle viscous pastes and advanced chemicals effectively with the support of both vacuum and pressure processes. Known for its efficient customisation, prototyping, and delivery of full-scale production equipment, Ross facilitates a smooth transition from lab to plant mixing with little factory downtime.

- 5. IKA Werke (Germany)

Main Products: Laboratory overhead stirrers; dispersing machines; inline mixers.

Advantages: IKA offers labs and production facilities modular, digitally controlled mixers, which can be easily integrated to move from development to full-scale production. Some of the areas in which IKA specializes include high-shear dispersing and precision mixing, with customers in the cosmetics, pharmaceutical and chemical industries. IKA’s reputation is based on products that provide user-friendly functionality, exact handling procedures, and outstanding reliability with a history of pushing technological innovation and maintaining high quality standards.

- 6. Silverson Machines (UK)

Main Products: High-shear batch & inline mixers; homogenizers.

Advantages: The worldwide reputation of Silverson is due to the outstanding performance of its high-shear mixers and homogenizers in obtaining stable emulsions, accurate dispersions, and uniform blends. The fast and uniform particle size reduction is enabled by Silverson’s unique rotor-stator technology. The sturdy build and the simple to clean nature of Silverson mixers make them suitable for use in cosmetics, food, and pharmaceutical industries. Silverson has always delivered customised solutions and expert technical support for varied processing needs.

- 7. NETZSCH Group (Germany)

Main Products: Kneaders; conical mixers; vacuum drying.

Advantages: NETZSCH is an expert in producing robust mixing systems, with a keen interest in heavy-duty and high-viscosity materials. NETZSCH’s kneaders and vacuum mixers are renowned for their careful control, economy of energy, and long service life. NETZSCH’s flexible designs and sophisticated thermal control capabilities make their equipment particularly useful to industries such as battery production, plastics and specialty chemicals. These systems are excellent in handling demanding materials that require uniform consistency and total homogeneity.

- 8. Alfa Laval (Sweden)

Main Products: Rotary jet mixers; static mixers; high-pressure homogenizers.

Advantages: Hygienic engineering is one of the main characteristics of Alfa Laval’s mixers, which makes them particularly appropriate for biotechnology, food, and beverage industry. Their mixers are flexible in that they allow one to switch between low-shear and high-shear modes to accommodate both delicate and viscous materials. Alfa Laval offers reliable and sustainable production by combining energy-efficient solutions and accessible service globally. Alfa Laval’s mixers are intended to reduce downtime and increase output.

- 9. Euro-Mixer (Netherlands)

- Main Products: Ribbon blenders; paddle mixers; trough mixers.

- Advantages: Euro-Mixer specializes in the manufacture of high-efficiency ribbon and paddle mixers, specially designed to meet the needs of the food, feed, and chemical industries. Their equipment is designed to mix constantly while consuming low energy and releasing quickly. At the core of the capabilities of the Euro-Mixer is the ability to adjust agitators to protect delicate ingredients while achieving effective and even mixing. Their high sanitary standards and commitment to simple, intuitive operation help Euro-Mixer to be known as a reputable European manufacturer.

-

- 10. KINEMATICA AG (Switzerland)

- Main Products: Ultra-turrax; high-shear lab & production dispersers.

- Advantages: KINEMATICA is known for its high-shear dispersion solutions expertise, which is committed to assisting customers to quickly move their processes from lab to full production. The Ultra-Turrax technology is designed to provide superior homogenisation, emulsification and particle reduction. The application of high-speed capabilities, up to 28,000 rpm, along with modular tools, enables KINEMATICA mixers to reproduce processes with precision. Pharmaceutical, biotechnological, and fine chemical industries highly value the precision, reliability, and long-term quality of Swiss engineering.

Industrial Mixer Applications: Which Manufacturer Fits Your Needs?

Since industrial mixers are used in different industries, it is important to match your application with the best machine and manufacturer. Vacuum emulsifying mixers in particular are irreplaceable in the cosmetics and personal care industry, with the emphasis on creams and serums that require 100% air bubble-free processing. Ribbon or paddle blenders are especially suitable for mixing dry powders or granular materials in such industries as food and chemical manufacturing. In pharmaceutical emulsions and fine suspensions, high-shear mixers are considered to be the best solution due to their special ability to obtain uniform particle size reduction.

It is important to determine the manufacturer’s unique expertise when making the choice. In the pharmaceutical industry, manufacturers such as IKA and SPX FLOW are leaders in sterile processing and their ability to take laboratory results to production environments. YUANYANG provides customized emulsifying systems for cosmetics with integrated filling functions. Our high-performance kneaders are suitable for challenging tasks such as plastics and battery paste production, thanks to their excellent performance. A well-informed evaluation of a machine should include an evaluation of the specifications of the machine and the degree to which the manufacturer shows expertise applicable to your industry’s unique regulatory context, challenges, and continuous research and development. Going forward, we’ll explore options for acquiring such equipment and walk you through the process of making your purchase.

Where to Buy from the Best Industrial Mixer Manufacturers

Selecting high-quality manufacturers is more than just buying equipment, it involves cooperation for consultation, personalization, and specific service arrangements. Many reputable brands start their partnership by attempting to understand the technical specifications of your operations. mixing time, fluid thickness, capacity needs, temperature control necessity, and cleaning efficiency. Once your input is defined, you will get custom design options, exact documentation, and assurances of your system’s functionality and reliability.

Take into account the time frame for orders, logistics in transit, and type of support you will get after the sale when engaging in international business. Both YUANYANG and Alfa Laval have strong networks of delivering products abroad and providing continuous services overseas. Wherever possible, it is advantageous to watch factory test demonstrations or examine the production facilities. Ensure that your contract specifies the warranty, availability of spare parts, and the service obligations of the provider. These aspects are very important in ascertaining how much your mixer will cost you and how effective it will be over time.

Conclusion

Choosing a suitable industrial mixer manufacturer has consequences for the efficiency of your production and the level of quality and compliance you maintain. By 2025, YUANYANG, GEA, SPX FLOW, and other companies will dominate the market due to their integration of advanced technology, a customized experience, and comprehensive customer care. Whether you are dealing with blending creams, emulsifying pharmaceutical syrups, or creating dry powders, it is important to select a manufacturer who will meet your equipment’s performance requirements for years.

Read about the particular competencies, quality control procedures, and support systems offered by various manufacturers. Once you choose the right manufacturer, your mixing system is an integral part of your business’s long-term success.

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Ultimate Guide to Filling Machine 2026 : Application & Selection

Homogenizing Mixer

Do you supply steam generator and provide steam and cooling pipes together for the mixing tank with homogenizer machine?

If the mixing tank is with steam heating, we will help to supply steam generator and provide steam and cooling pipes. But this is an optional choice. Client can prepare by steam generator by himself. The steam pipe is usually quoted separately.

Sachet Packaging Machine

Can I use this liquid packing machine to pack if my product is like paste which is quite thick and viscous?

Yes, heating function and mixing function can be added based on materials.

Cosmetic

Can the equipment handle organic or sensitive formulations?

Yes. Our equipment is designed to handle various special formulations, including organic, additive-free, and sensitive formulations, ensuring no contamination or degradation during processing.

Water Filling Machine

Does it have counting function?

On the desktop filling machine, there is counter displaying how many bottles have been filled.

Aluminum Foil Sealing Machine

What’s the cooling method of the bottle lid sealing machine?

This bottle lid sealer adopts air cooling method.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery