Automatic Labeling Machines

Discover High-Performance Automatic Labeling Machines from YUANYANG

Streamline Your Production Line with Automatic Labeling Machines

Take your packaging process to the next level with YUANYANG’s state-of-the-art automatic labeling machines. Designed for speed, accuracy, and reliability, our labeling solutions ensure every product receives a perfectly placed label—no matter the shape or size. Enhance your production efficiency and product presentation with YUANYANG’s expertly engineered automatic labeling machines.

Versatile Solutions for Various Industries

Our automatic labeling machines are compatible with bottles, jars, boxes, and more—across food, cosmetics, pharmaceuticals, chemicals, and other industries. Whether your production line requires front and back labeling, wrap-around labeling, or customized applications, YUANYANG offers the versatility to meet your specific needs.

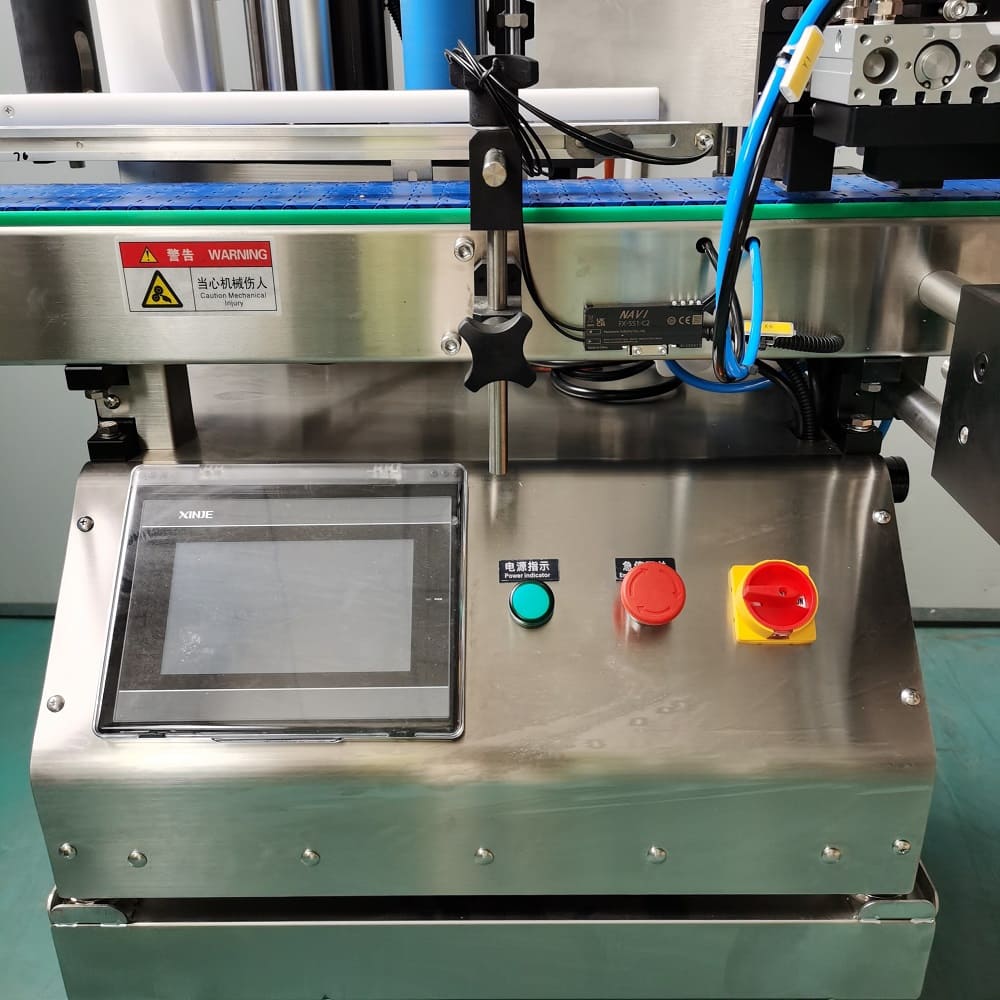

Advanced Technology for Precision and Efficiency

Equipped with advanced sensors and programmable controls, YUANYANG’s automatic labeling machines minimize human error and maximize consistency. Enjoy seamless integration with existing production equipment and quick changeovers for different product types, saving valuable time during your labeling process.

Robust Build and Easy Maintenance

Crafted with durable, high-quality materials and precision engineering, our automatic labeling machines ensure long-term performance with minimal downtime. YUANYANG provides comprehensive technical support, free training, and turnkey installation services to keep your operation running smoothly.

Why Choose YUANYANG for Your Automatic Labeling Needs?

- Expert factory with a proven record since 2008

- European CE certificates for health and safety

- Complete production line solutions, including filling, capping, and more

- Customized and one-stop services from consultation to installation

Upgrade your manufacturing line today with efficient automatic labeling machines from YUANYANG, your trusted partner in industrial automation.

automatic labeling machine Display

How many bottles can the cream filler fill per hour?

The filling speed is affected by many factors, such as the materials thickness, viscosity, operation speed by staffs, pneumatic speed adjustment, filling volume, pressure. The filling speed varies from 500-2400 bottles per hour.

Can this tank be used for your lift mixer also?

Yes, the tank can be used for our lift mixer. We normally recommend clients to buy tank together if clients purchased the lift mixer machine, which can ensure the tank is 100% suitable for our mixer. Client can also prepare tank by himself. We will tell the suitable tank size and height.

How do you ensure the long-term stable operation of the equipment?

We provide comprehensive after-sales services, including installation, debugging, training, and regular maintenance, ensuring stable equipment operation.

What’s the purpose of sealing the packages?

Automated sealing machine has high sealing effect, which can ensure the hygiene and safety of the food, extend the shelf life of the food, to prevent chemical reactions or deterioration, to avoid the leakage and pollution of drugs.

How many bottles can this automatic labeling machine for bottles per minute?

Yes, this round bottle sticker labeling machine is suitable for sticking labels on glass bottles.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery