Complete Personal Care Filling Line Solution for Liquid Products

Explore our automated filling line solutions for personal care products.

Boost your productivity and packaging precision with our fully customizable filling, capping, and labeling systems—designed for shampoos, lotions, creams, and more.

Complete Personal Care Filling Line Solution for Liquid Products

In the fast-evolving personal care industry, manufacturers face the dual challenge of product variety and operational efficiency. Whether it's shampoos, lotions, conditioners, or body washes, maintaining speed, hygiene, and consistency is essential. A modern personal care filling line equipped with automated systems offers the ideal filling line solution to meet these demands and drive growth.

Why the Personal Care Industry Needs Automatic Filling Line Solutions

🔹Meeting the Growing Demand for Custom and Premium Products

Consumers are increasingly seeking personalized, high-performance, and eco-conscious personal care products. As product portfolios expand, traditional manual or semi-automatic processes fall short. Manufacturers need a scalable and flexible filling line solution that can quickly adapt to diverse product types and packaging formats.

🔹The Role of Automation in Modern Personal Care Filling Lines

Automated systems not only increase production speed but also enhance accuracy and hygiene compliance. Integrating a complete personal care filling line with smart technologies helps reduce downtime, support fast changeovers, and maintain consistent product quality across batches.

Challenges in Personal Care Filling Line Operations

🔸Viscosity Variations and Foam Control

Personal care products range from watery toners to thick creams and gels. Each requires specific filling technology—such as gravity fillers, piston fillers, or gear pumps—plus anti-foam mechanisms to ensure spill-free and precise dosing.

🔸Diverse Packaging Requirements

Packaging varies greatly in shape, size, and material. A flexible filling capping labeling machine must seamlessly handle flip-top bottles, pump dispensers, sprayers, and more—without compromising throughput.

🔸Hygiene and Regulatory Compliance

Compliance with international standards such as GMP, FDA, and ISO is non-negotiable. A properly designed personal care filling line must support easy cleaning, sanitation, and validation processes.

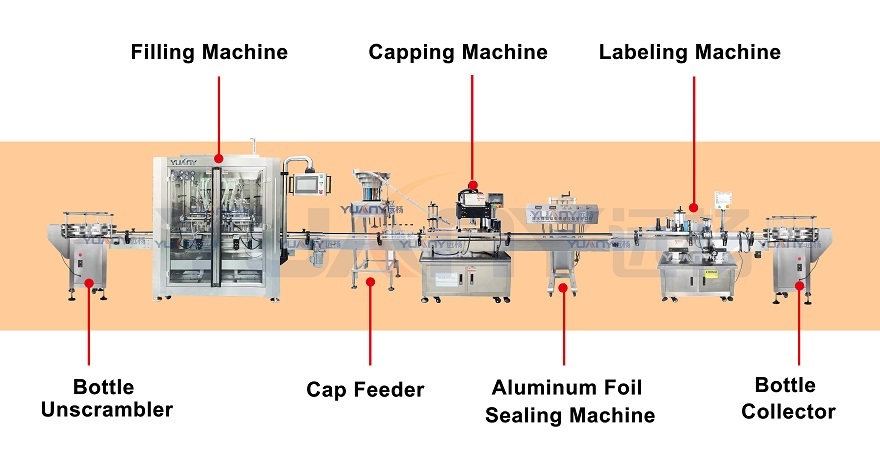

Key Components of a Complete Filling Capping Labeling Machine System

✅1. Bottle Feeding System

Automated bottle unscramblers or inline conveyors align and feed bottles efficiently into the production line, supporting various shapes and sizes without manual handling.

✅2. Liquid Filling Machine

Depending on the product viscosity, the filling machine may use piston, peristaltic, or gravity technologies.

Features include:

High-precision dosing with ±1% accuracy

Anti-drip nozzles and foam suppression

Multiple nozzles for higher throughput

✅3. Automatic Capping Machine (+optional cap feeder)

Handles a variety of cap types, including screw caps, pump tops, and sprayers.

Key features:

Torque-controlled tightening

Automated cap feeding and orientation

✅4. Aluminum Foil Sealing Machine

-

Compatible with plastic and glass containers

- Strong seal, leakproof and fresh

- Safe and professional look

- ✅5. Labeling and Coding System

The filling capping labeling machine integrates

Front/back, wrap-around, and tamper-evident labeling

High-speed print-and-apply systems

Inkjet or laser coders for batch and expiry information

✅6. Inspection and Quality Control

Vision systems and checkweighers ensure:

Proper cap placement and torque

Label accuracy and alignment

Detection and rejection of faulty units

✅7. Conveyor and Central Control System

Modular conveyors connect all line components, managed via PLC and HMI systems that offer

Centralized control and monitoring

Recipe memory for various SKUs

Remote access and maintenance alerts

Technical Innovations in Personal Care Filling Line Solutions

🚀Handling High-Viscosity Products with Precision

Servo-driven piston fillers and heated lines allow accurate filling of thick creams and gels without clogging or residue.

🚀CIP/SIP and Tool-Free Changeover for Efficiency

Clean-in-place and sterilize-in-place systems reduce downtime and ensure compliance, while tool-free changeover simplifies SKU switching in under 10 minutes.

🚀Smart Sensors and IoT for Intelligent Production

Real-time monitoring, predictive maintenance, and data analytics help optimize production and ensure full traceability across the filling line solution.

Customization and Scalability of Filling Capping Labeling Machines

🛠️Flexible Configurations for Different Production Needs

From semi-automatic stations to high-speed rotary lines, every filling capping labeling machine system can be tailored to fit your production scale and budget.

🛠️Scalable Filling Line Solutions for Growing Demand

Add more filling heads, inspection modules, or packaging components as your production volume increases—without replacing the entire line.

🛠️Global Compatibility and Compliance

Multi-language HMI interfaces and adherence to regional safety and sanitation standards make these systems ideal for global brands and contract manufacturers alike.

Real-World Applications of Personal Care Filling Line Systems

✨For Cosmetic Manufacturers

Perfect for creams, serums, and facial products that require clean dosing and precise packaging.

✨For OEM/ODM Production Lines

Streamlines operations for manufacturers producing multiple formulas and packaging styles for different clients.

✨For Daily Chemical and Hygiene Products

Efficiently fills hand soaps, sanitizers, and deodorants while ensuring hygiene and batch consistency.

Conclusion: Future-Proof Your Business with the Right Automatic Filling Line Solution

A well-integrated personal care filling line delivers far more than speed. It ensures product consistency, reduces manual labor, supports fast changeovers, and meets strict hygiene requirements. Whether you're scaling up or starting out, investing in the right filling line solution and filling capping labeling machine system is essential for long-term success in the personal care industry.

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Water Filling Machine

What liquid is it suitable for ?

No, this is water filling machine, only suitable for liquids like water, drinks, milk, perfume, eye drops...

Liquid Soap Mixer

Which do you recommend, steam heating or electric heating?

To save cost, electric heating is recommended, especially for small capacity soap mixing tank; Steam heating requires a steam generator, if client has steam generator, steam heating is recommended.

Automatic powder feeder machine

Do you also supply powder or granules packing machine?

Yes,Yuany supplies different type of packing machines for powder, granules and liquids. Please contact customers services with details.

Cosmetic

What maintenance and support do you provide for the equipment?

We provide detailed equipment maintenance guides and offer regular maintenance services to ensure long-term optimal performance. Additionally, we offer quick-response after-sales technical support to resolve any unexpected issues.

Vertical Filling Machine

Can it fill the paste like dough?

No, the dough is too viscous and can’t flow down. The materials must be easy to flow down for this vertical filling machine. And for too viscous paste, pressure filling machine or heating mixing filling machine will be recommended based on materials.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery