How Lotion Is Made: Step-by-Step Guide for Home and Factory Production

Discover how YUANYANG’s Cosmetic Mixer and Lifting Homogenizer Mixer streamline lotion production in our step-by-step guide, detailing both home and factory methods. Learn efficient, quality techniques to make smooth, effective lotions with our expert equipment insights.

- Simple Lotion Making Formula

- Lotion Labels Real Ingredients

- Comparing the Ingredients of Lotion in Various Products

- Comparison of Two Lotions of the same scent

- Lotion One: Components and Their Role

- Lotion Two: Ingredients and Their Function

- A comparison of Lotions Sold as Skin Protection

- Lotion Three: Components and Their Role

- Lotion Four: Components and Their Role

- Alternatives to Water

- Emulsifying Wax Choices

- Other Customization Ingredients

- Significance of Preservatives

- Additive customization

- Lotion Manufacturing in a Factory: Industrial Perspective

- Mixers: Increasing the level of Lotion Production

- Selecting the Right Mixer

- For Batch Production: 200L Cosmetic Mixer

- For Flexible and Scalable Mixing: Lifting Homogenizer Mixer

- Why YUANYANG Mixers?

Simple Lotion Making Formula

The basic formula of making lotion at home or in a factory is:

70-80 percent Distilled Water

3-6% Emulsifier

3-5% Co-Emulsifier

Oils and Butters 8-23%

1% Preservative

Lotion Labels Real Ingredients

In the case of skincare, the path to learning the process of lotion production reveals an interesting world of ingredients that interact in harmony. There are eight main types of ingredients that are usually used in lotions and each has a purpose.

1. Emollients

Emollients like water, cetyl esters, glyceryl dilaurate, lanolin oil are important to keep the skin soft and smooth.

2. Emulsifiers

Emulsifiers are cetearyl alcohol, cetyl alcohol, ceteareth-20, lanolin oil, and acrylates/C10-30 alkyl acrylate crosspolymer, which keep the ingredients that have dissimilar properties mixed.

3. Fragrances

Fragrance is a mandatory ingredient, which gives that nice smell that lotions are usually known to have.

4. Humectants

Glycerin is a popular humectant that aids in drawing and locking moisture on the skin.

5. Occlusives

Lotions contain occlusive agents such as lanolin oil and dimethicone, which are oil-based products, to reduce evaporation of moisture.

6. PH Adjusters

Sodium hydroxide is used to control the PH of the product to make it safe to apply on the skin.

7. Preservatives

Alcohol denat., chlorphenesin, and benzyl alcohol are preservatives that prevent the growth of unwanted bacteria and fungi.

8. Solvents

The ingredients are dissolved and combined with the help of solvents such as water, alcohol denat., and benzyl alcohol.

Comparing the Ingredients of Lotion in Various Products

Comparison of Two Lotions of the same scent

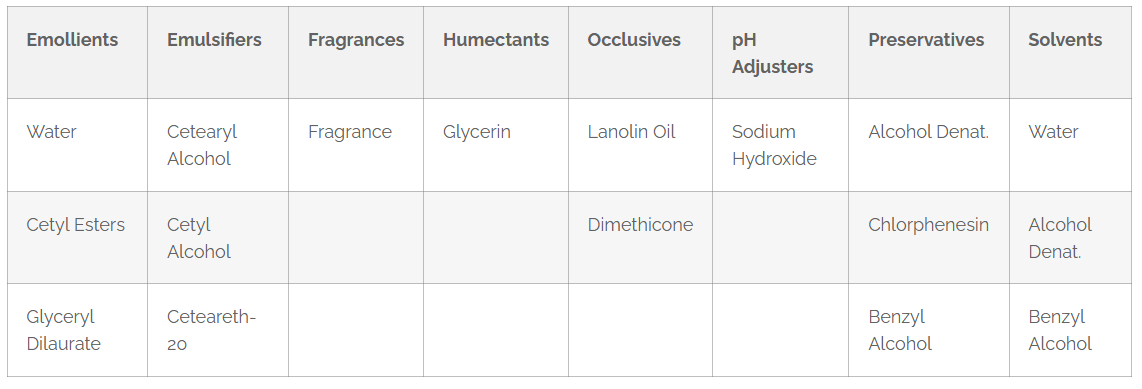

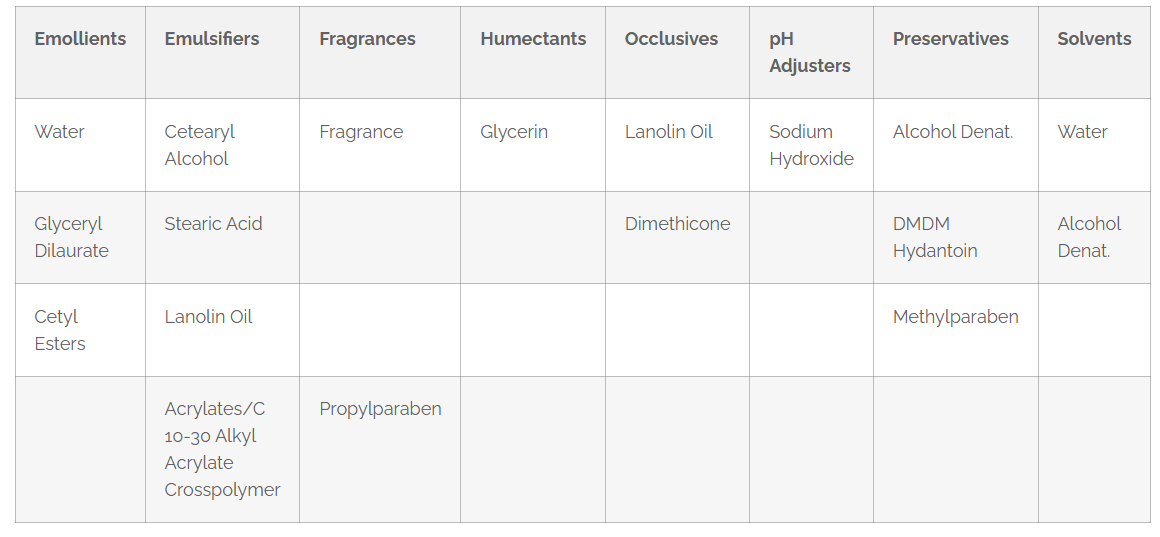

So, let us take a closer look at the ingredient list of two lotions that are sold under the same fragrance and know what they are used for:

Lotion One: Components and Their Role

Lotion Two: Ingredients and Their Function

A comparison of Lotions Sold as Skin Protection

Now, passing to the lotions, which are sold as skin protectants, these products, which are over-the-counter drugs, contain certain active and inactive ingredients:

Lotion Three: Components and Their Role

Active Ingredient: dimethicone 1.2% (skin protectant ingredient)

Inactive Ingredients: water, glycerin, distearyldimonium chloride, petrolatum, isopropyl palmitate, cetyl alcohol, avena sativa (oat) kernel flour, benzyl alcohol, sodium chloride

Lotion Four: Components and Their Role

Active Ingredient: Dimethicone 1.3% (skin protectant ingredient)

Inactive Ingredients: water, glycerin, distearyldimonium chloride, petrolatum, isopropyl palmitate, cetyl alcohol, avena sativa (oat) kernel flour, benzyl alcohol, sodium chloride

Alternatives to Water

While distilled water is the most popular base, looking into botanical liquids such as aloe, jasmine essential water or cucumber essential water can give your homemade lotion a special something.

Emulsifying Wax Choices

It is important to select the appropriate emulsifying wax. They can be generic emulsifying wax, heavy-duty Polawax, plant-based Bio-Mulsion Wax and conditioning BTMS-50.

Other Customization Ingredients

Stearic acid, cetearyl alcohol and cetyl alcohol are used to thicken and stabilize emulsions.

The lotion is enriched with different oils such as sweet almond, olive, and shea butter that add different properties to the lotion.

Significance of Preservatives

Optiphen or Phenonip is a preservative that is crucial in inhibiting the growth of molds and bacteria in homemade lotions.

Additive customization

You can customize your lotion by adding extracts, glycerin, honeyquat and others.

Lotion Manufacturing in a Factory: Industrial Perspective

The process of making lotions is a highly technical process. Everything, including the acquisition of ingredients and filling the tubes, is a part of the quality of the final product.

Cosmetic creams and lotions may be oil-in-water or water-in-oil emulsions, and contain emollients, lubricants, emulsifying agents, thickeners, perfume, color, and preservatives.

On the industrial front, the process of manufacturing cosmetic creams and lotions is a very painstaking one. So what are the main points?

1. Formulation and Recipe Development:

Ingredients Selection: The formulators choose a blend of emollients, emulsifiers, humectants, occlusives, fragrances, pH adjusters, preservatives, and solvents depending on the attributes of the product required.

Customization: The formulation can be customized according to the type of product (e.g. moisturizing, anti-aging or sunblock lotions) and provide specific skin benefits.

2. Mixing and Weighing:

Precision Weighing: Weighing of the ingredients precisely is essential in consistency. Sophisticated weighing machines guarantee the correct amounts.

High-Speed Mixing: High shear mixers or homogenizers mix ingredients to create a stable and homogenous emulsion.

3. Heating and Cooling:

Emulsification: Heating will help in melting solid ingredients, and enhance emulsification. Cooling is then done to stabilize the emulsion and get the desired texture.

Temperature Control: Temperature control is crucial to avoid degradation of ingredients and to guarantee the quality of the products.

4. Introduction of Active Ingredients:

Specialized Additions: In case the lotion has active components such as vitamins or botanical extracts, they are added at certain points to maintain their effectiveness.

Homogeneous Distribution: Methods like microfluidization or extra mixing steps guarantee the homogeneous distribution of active components.

5. pH Adjustment:

pH control: Sodium hydroxide or citric acid is added to control and maintain the pH of the lotion within the range of pH that is compatible with the skin.

6. Quality Control and Testing:

Viscosity Testing: Rheometers are used to check the viscosity of the lotion to make sure that it has the required consistency.

pH Testing: Periodic pH tests ensure that the lotion is within the given pH range.

Microbial Testing: Testing of microbial contamination is done rigorously to make sure that the products are safe.

Stability Testing: Stability testing is done on products to determine the shelf life of the product under different conditions.

7. Filling and Packing:

Automated Filling: The lotion is filled accurately in containers with the help of automated filling machines and the wastage is minimal.

Aseptic Packaging: The packaging materials and processes ensure the sterility of the product and avoid contamination.

8. Labeling and Batch Coding:

Regulatory Compliance: Labels contain ingredients, usage directions and any necessary regulatory information.

Batch Coding: A unique code is assigned to each batch of products to trace and to control their quality.

9. Final Inspection:

Visual Inspection: A visual check is done on the finished products to ascertain that the products are of good quality.

Packaging Integrity: Seals, caps, and packaging materials are checked in terms of integrity.

Mixers: Increasing the level of Lotion Production

YANGYANG's Mixers are critical in solving issues in the production of lotions. Their accuracy in mixing helps in the distribution of ingredients uniformly thus producing lotions of high quality.

Stage 1: Precision Mixing with Yuanyang Mixers

YANGYANG's Mixers have a high-speed rotation and strong suction, which makes them evenly distributed and well-blended. The result? The characteristic feature of high-quality lotions is a homogeneous mixture.

Stage 2: Disintegration of Agglomerates

YANGYANG's Mixers are designed to effectively break up agglomerates, which ensures fast and total hydration of thickening agents.

Step 3: Spreading Important Ingredients

The last stage is the dispersion of important ingredients, the homogeneous texture is obtained, and the desired properties are preserved.

Selecting the Right Mixer

When it comes to lotion production—whether at a small scale or in a full-scale industrial setting—selecting the right mixer is critical to achieving consistency, stability, and product quality. YUANYANG’s advanced mixing equipment offers a versatile and effective solution for every stage of lotion-making, from emulsification to homogenization.

For Batch Production: 200L Cosmetic Mixer

YUANYANG’s 200L Vacuum Emulsifying Mixer is ideal for medium-scale cosmetic production, especially lotions with viscosities ranging from 10,000 to 50,000 cps. This fixed-cover system integrates oil, water, and emulsifying phases into a single, streamlined unit. With high-speed homogenization and vacuum defoaming functions, it delivers fine particle distribution (down to 2 microns) and stable emulsions that resist separation over time.

Key Benefits:

- Integrated vacuum system to eliminate air bubbles

- Rapid and uniform emulsification

- Stainless steel build compliant with GMP standards

- Ideal for creams, lotions, gels, and ointments

-

For Flexible and Scalable Mixing: Lifting Homogenizer Mixer

For manufacturers requiring more flexibility and ease of operation, the Lifting Homogenizer Mixer offers an efficient alternative. With a lifting head for easy cleaning and ingredient loading, this mixer is designed to process a wide range of batch sizes (from 50L to 500L). It features high shear rotor-stator technology, ensuring fast dispersion and even texture, especially in formulations rich in oils, waxes, or botanical additives.

Why Choose It:

- Adjustable speed via frequency inverter

- Easy-to-clean design with lifting emulsifying head

- Suitable for both pilot and scaled-up production

- Excellent for emulsions that require high-shear mixing and ingredient dispersion

-

Why YUANYANG Mixers?

YUANYANG’s mixers are engineered with precision, hygiene, and efficiency in mind. Whether you’re crafting a boutique skincare line or operating a large-scale cosmetics factory, our mixers help streamline production, reduce waste, and maintain consistent product quality. With user-friendly controls, stainless steel construction, and customizable options, YUANYANG stands out as a trusted partner in lotion manufacturing.

FAQs

1. Is milk used to make lotion?

In spite of myths, milk is not recommended in lotions because it has a short shelf life.

Preservatives prevent mold and bacteria but they do not increase shelf life of milk.

Alternatives such as aloe, jasmine essential water or rose water are also available.

2. What role do GYUANYANG Mixers play in lotion production?

YUANYANG Mixers ensure the even mixing, emulsification, and smooth texture of lotions.

3.What is the history of lotions and how did the ancient remedies turn into modern marvels?

The ancient care of the skin consisted of various mixtures; the modern lotions were developed in the 19th century.

The history of the evolution led to the modern advanced and efficient skin care products.

4. Is it possible to use milk alternatives in making lotions?

Special formulations can be considered, such as milk alternatives, such as almond or oat milk.

Make sure alternatives are distilled or purified and have preservatives inbuilt to have a long shelf life.

7 Dangerous Mistakes Most Companies Make with Underground Storage Tanks (USTs)

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Liquid Soap Mixer Machine

How can you guarantee the bottom homogenizer will not leak liquids?

The bottom homogenizer adopts German mechanical sealing, As long as clients operate correctly, follow the instructions, this leakage is hardly to happen for over tens years or longer. But once the leakage accrues, just contact us to get a mechanical sealing to replace it.

Machine seal, as an indispensable sealing element in mechanical equipment, its core function is reflected in many aspects. First of all, it effectively prevents the leakage of liquid, gas or solid particles inside the machine through a tight sealing effect, as well as the intrusion of external impurities, so as to ensure that the internal environment of the machine is dry and clean.

This function is essential for extending the service life of machine equipment. Secondly, when the machine is sealed at high speed, it can prevent the condensation of water vapor caused by the heat generated by friction and play an anti-fog role. At the same time, it can effectively isolate the dust, particles and impurities generated during the work process to protect the equipment from damage.

In addition, the seal can also play an excellent waterproof role in wet environments, ensuring that the inside of the equipment is not affected by water erosion. In summary, the seal not only protects the normal operation of the mechanical equipment, but also provides a strong guarantee for the production and family life of all walks of life through its excellent sealing performance.

Cosmetic

Does your equipment support automated production?

Yes. Our equipment is highly automated, capable of full automation from ingredient preparation, mixing, emulsifying to filling and sealing, greatly reducing manual intervention and increasing production efficiency.

Aluminum Foil Sealing Machine

Can I put the lid sealer machine on the metal floor?

No, it is strictly prohibited to put the seal on the case or large area of metal, so as to avoid burning the power tube

Detergent powder mixer

Can you also help to purchase raw powder for the washing powder mixer?

Sure, we have professional partner who has been engaged in raw powder supply for over 20 years. The price is competitive in the market. If clients need to purchase together, it is recommend to take a container.

Powder Sachet Packaging Machine

Can the plastic powder packing machine print barcode also?

No, the standard type of coding machine on this packing machine for powders can only print date. To print barcode, customize service will recommend client another separated jet printer.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery