YUANYANG Emulsifier Mixer Solutions for Industrial Production

Industrial Emulsifier Mixer Solutions by YUANYANG

YUANYANG is a leading Chinese manufacturer of industrial mixers and agitators, specializing in emulsifier mixer systems including vacuum homogenizers, vacuum emulsifying mixers and high-shear mixers. Since 2008 we have delivered reliable equipment and full production lines that meet diverse process needs across cosmetics, pharmaceuticals, food, and chemicals. Our experience and CE certifications demonstrate our commitment to safety and regulatory compliance.

Key Features & Applications

Our emulsifier mixer range offers high-shear dispersion, uniform particle size reduction, stable emulsions and gentle vacuum processing for degassing. Typical applications include creams, lotions, ointments, sauces and specialty chemical products. YUANYANG designs each emulsifier mixer to optimize mixing time, reduce energy consumption and improve product consistency for scalable production.

Advanced Technology & Compliance

YUANYANG integrates robust mechanical design with precision control systems to deliver repeatable results. Our vacuum emulsifying mixers combine homogenizing heads, high-shear rotors, and vacuum jackets for efficient heat control and contamination prevention. Multiple CE certifications confirm that our equipment meets essential health and safety requirements for EU markets.

Turnkey Production Lines & Support

Beyond single machines, YUANYANG supplies complete turnkey lines including mixing equipment, storage tanks, filling, capping, labeling, sealing machines, inkjet printers and water treatment. We provide free technical training, one-stop installation support and commissioning to ensure smooth start-up and operator competence.

Why Choose YUANYANG

With years of industry expertise, a full-service offering, and a focus on quality and safety, YUANYANG delivers dependable emulsifier mixer solutions tailored to your process goals. Our global vision is to be the world’s best industrial mixer and agitator manufacturer, backed by practical experience and ongoing customer support.

Contact & Next Steps

Explore emulsifier mixer models and turnkey options at https://www.yuanymachinery.com/ or contact us at [email protected] for a consultation, quote, or technical inquiry. Let YUANYANG help you scale production with efficient, compliant emulsifier mixer systems.

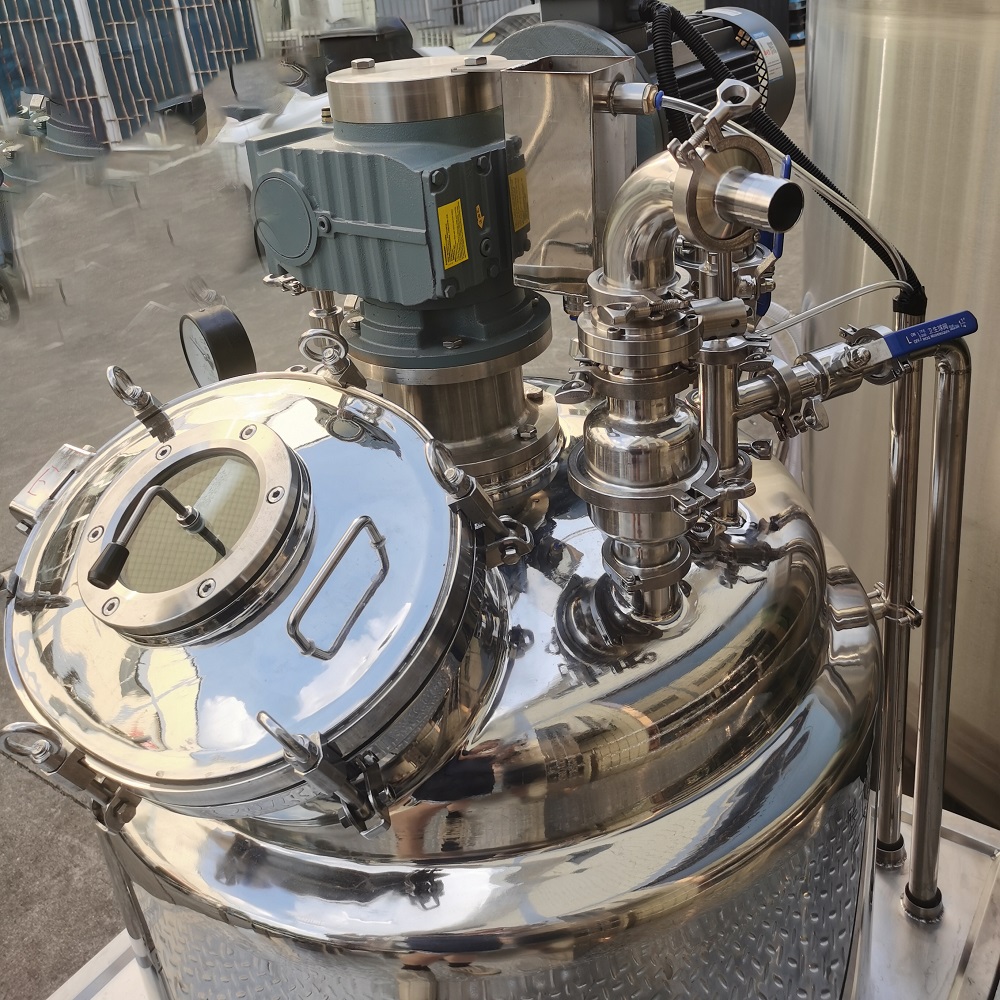

emulsifier mixer Display

What capacity do you provide for vacuum emulsifying mixer machine?

We can supply from 50 Liters to 5000 Liters for mixing tanks,but we recommend maximum 1000L for vacuum emulsifier homogenizer,whose the package sizes is just ok for regular 40” HQ container.

What maintenance and support do you provide for the equipment?

We provide detailed equipment maintenance guides and offer regular maintenance services to ensure long-term optimal performance. Additionally, we offer quick-response after-sales technical support to resolve any unexpected issues.

What’s the distance between the bottle neck and sealing head for the best sealing effect?

Generally, the distance between cap and sealing device is no more than 5 mm, and for large diameter bottle,make the distance 8 mm. The longer distance, the weaker power becomes, the larger bottle,requires larger working power.

What’s the thickness of the stainless steel tank for liquids?

The standard thickness for finished products is 3mm, the water tank thickness is 2mm. But the bigger capacity, the layer will be thicker.

What type of water can we use for this pure water filter ?

The raw quality (conductivity) should be ≤300μs/cm), such as city tap water, lake water, underground water, river water...

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery