Manufacturer of Liquid Washing Production Equipment

About the manufacturer Yuanyang, and main features of liquid washing production machine

About the manufacturer and Yuanyang’s Service

Yuanyang is a manufacturer of liquid washing production equipment and a professional solution provider of a complete filling line solution. Yuanyang not only manufactures liquid washing machines but also provides on-site installation service for the client.

At Yuanyang, clients receive a comprehensive one-stop solution—from initial consultation, tailored design, and technical problem-solving to plan drafting and accurate quotations. Solutions are developed based on each client's budget and local conditions. The equipment provided is durable, multi-functional, and high-performing, ensuring long-term value.

Yuanyang is known for its dedicated after-sales service, including professional teams for technical support, certification, installation, and maintenance. With over 17 years of experience, Yuanyang has built a strong reputation in the domestic market and ranks among the top suppliers of liquid soap mixing and cosmetic production machinery.

Main Features of Liquid Washing Production Machine

Yuanyang’s liquid washing machine is primarily a homogenizing and emulsifying system, which consists of four integrated subsystems: tank body, mixing system, homogenizing system, and heating system.

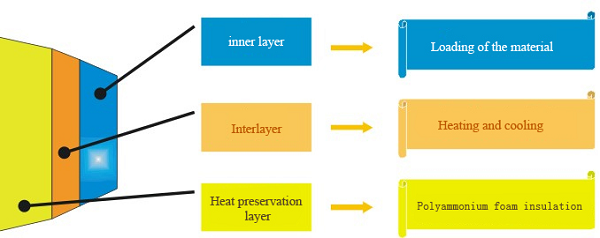

1. Tank Layers

-

Constructed with a three-layer stainless steel structure:

-

Inner layer for direct contact with materials

-

Middle jacket for heating or cooling

-

Outer layer for insulation and safety protection

-

-

The double-jacketed design ensures efficient heat transfer and energy saving.

-

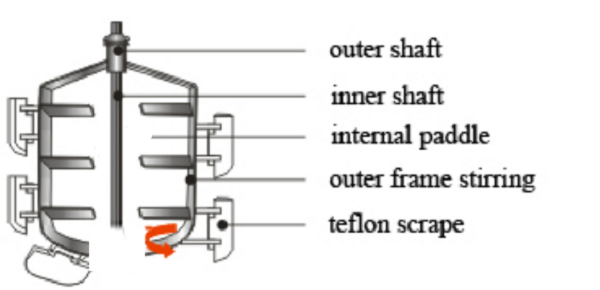

2. Mixing System

-

The mixer is equipped with a top-mounted frame-type mixing paddle, featuring one-way wall scraping and frequency-controlled speed.

-

The scraper prevents material buildup on the tank wall, and the paddle effectively blends water, oil, powders, and other ingredients into a uniform product after sufficient mixing.

-

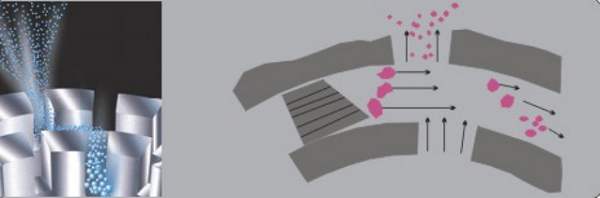

3. Homogenizing System

-

The homogenizer head is composed of a motor, rotor, and stator.

-

The homogenizer uses a special double-end mechanical seal with water-circulating cooling to ensure sealing performance and equipment longevity.

-

A high-speed rotating shaft driven by a self-positioning spindle generates centrifugal force, pulling materials through the homogenizing head.

-

The material undergoes strong radial jetting, high shear, friction, tearing, and impact

-

These forces break down particles and allow full dispersion, emulsification, and homogenization. The cycle repeats to ensure a consistently refined end product.

-

4. Heating System (Optional)

-

The heating method depends on the product formulation.

-

Two available heating options:

-

Electric Heating: An electric heater is inserted into the bottom jacket. Tap water in the jacket heats up and transfers warmth to the inner tank layer.

-

Steam Heating: Requires a steam generator to supply steam into the jacket, achieving the same heat-conducting effect as electric heating.

-

-

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Liquid Soap Mixer Machine

Do you also provide liquid soap formula and technical training for a new user?

Yes, Yuany is experienced in liquid soap production for many years. We can provide professional training and teach face to face for clients. Don’t hesitate to contact us.

How can you guarantee the bottom homogenizer will not leak liquids?

The bottom homogenizer adopts German mechanical sealing, As long as clients operate correctly, follow the instructions, this leakage is hardly to happen for over tens years or longer. But once the leakage accrues, just contact us to get a mechanical sealing to replace it.

Machine seal, as an indispensable sealing element in mechanical equipment, its core function is reflected in many aspects. First of all, it effectively prevents the leakage of liquid, gas or solid particles inside the machine through a tight sealing effect, as well as the intrusion of external impurities, so as to ensure that the internal environment of the machine is dry and clean.

This function is essential for extending the service life of machine equipment. Secondly, when the machine is sealed at high speed, it can prevent the condensation of water vapor caused by the heat generated by friction and play an anti-fog role. At the same time, it can effectively isolate the dust, particles and impurities generated during the work process to protect the equipment from damage.

In addition, the seal can also play an excellent waterproof role in wet environments, ensuring that the inside of the equipment is not affected by water erosion. In summary, the seal not only protects the normal operation of the mechanical equipment, but also provides a strong guarantee for the production and family life of all walks of life through its excellent sealing performance.

Hydraulic Lift Vacuum Mixer

How do you pack for the cosmetic emulsifier?

The emulsifying equipment will be wrapped with film first, then packed with wooden case. The machine is well-protected during shipment.

Homogenizer Mixing Tank with Circulation System

Can you send me a drawing of the industrial mixer tank with homogenizer?

Yes, we have professional designers to draw according to customized requirements, including the dimensions, parts, structures, wire drawing and so on.

FAQs

What’s your payment term?

Generally, we take 30% of total amount as down payment, which should be wired by T/T. The 70% balance will be paid by T/T after you inspect your machines before shipment. We also accept letter of credit although it takes more expenses. But our bank should confirm your opening bank’s credit first.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery