YUANYANG Perfume Filling Machines: Precision & Elegance in Every Drop

YUANYANG Perfume Filling Machines: Precision & Elegance in Every Drop

In the delicate world of perfumery, every drop counts. The essence of a fragrance demands not only masterful blending but also impeccable presentation. At YUANYANG, we understand that precision and efficiency are paramount for cosmetic and fragrance manufacturers. As a leading manufacturer of industrial mixers and a comprehensive provider of production line equipment since 2008, YUANYANG brings its expertise to the forefront with our advanced perfume filling machine solutions, ensuring your exquisite creations are bottled with care and accuracy.

Unparalleled Precision for Fragrance Perfection

Our perfume filling machines are engineered to deliver unmatched accuracy, critical for maintaining the integrity and value of your precious fragrances. Designed to handle various viscosities and bottle types, YUANYANG’s fillers minimize product loss while ensuring consistent fill levels across every unit. This meticulous attention to detail not only preserves the aesthetic appeal of your product but also guarantees a superior user experience, reflecting the high quality of YUANYANG. With YUANYANG, you invest in reliability and a flawless finish, batch after batch.

Seamless Integration & Automated Efficiency

Beyond individual machines, YUANYANG specializes in providing complete production line solutions. Our perfume filling machines integrate seamlessly with our other high-quality equipment, including our renowned vacuum homogenizers, storage tanks, capping machines, and labeling machines. This holistic approach enables a fully automated and highly efficient workflow, from initial mixing to final packaging. Reduce manual labor, increase throughput, and ensure consistent product flow with a YUANYANG integrated system, designed for optimal performance and scalability to meet your growing production demands.

YUANYANG's Commitment: Quality, Support & Turnkey Solutions

Choosing YUANYANG means partnering with a trusted industry leader. Since 2008, we have been dedicated to providing robust, reliable, and innovative equipment. Our commitment to quality is underscored by multiple CE certifications, affirming that our products meet stringent European safety and health standards. More than just machinery, we offer a comprehensive support package: free technical training, one-stop installation support, and a full set of turnkey services. From concept to commissioning, YUANYANG is your dedicated partner in achieving operational excellence. Join us in our vision to become the best industrial mixer and agitator manufacturer in the world, starting with your perfect perfume production line.

Discover how YUANYANG’s perfume filling machines can elevate your production. Visit yuanymachinery.com or contact us today for a tailored solution.

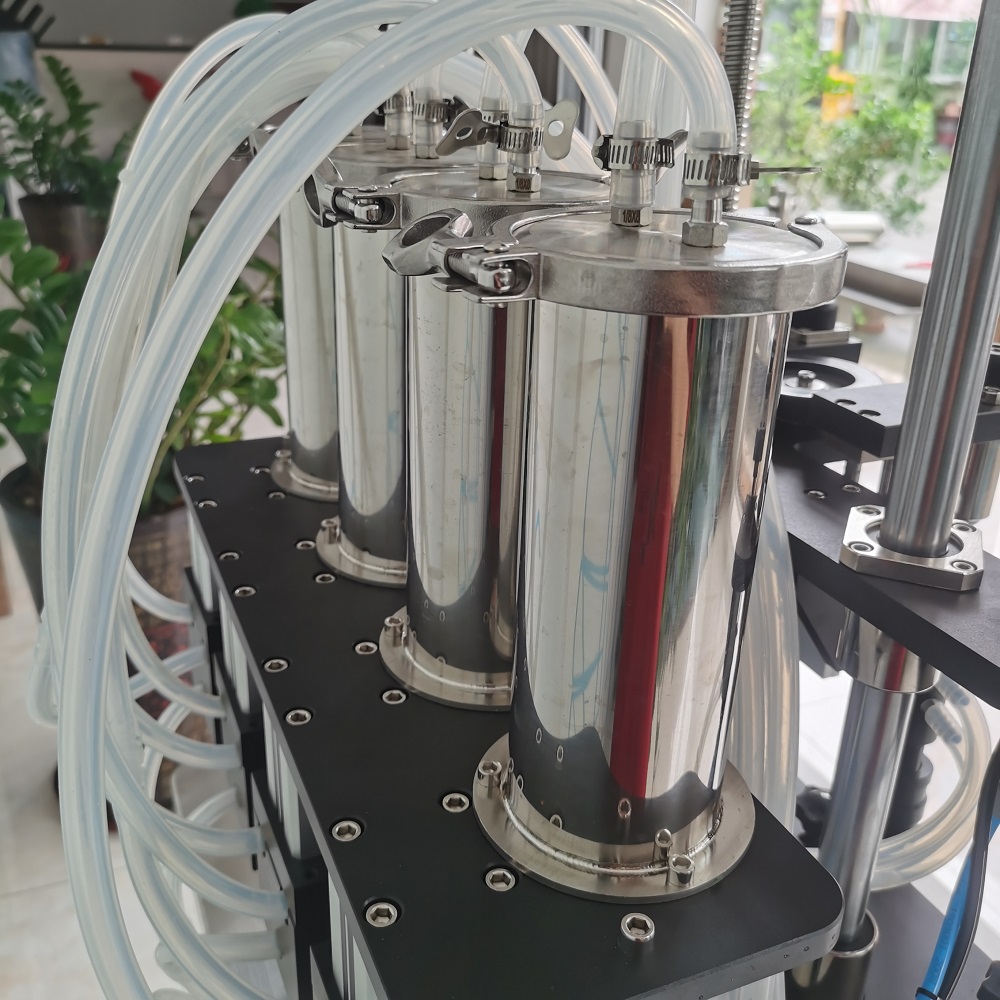

Perfume filling machine Display

How do I know the water conductivity?

The reverse osmosis water filter machine can display both raw water conductivity and output water conductivity.

What type of powders is the plastic bag packing machine suitable for?

The packing machinery for powders include various types such tea powder, walnut powder, mini granules, coffee powder, corn powder, rice powder, milk powder, etc.

Is it necessary to clean for each batch production?

There is no need to clean quite often for the same products. But for different products, it is better to clean every time before the production of different products.

Can the induction sealing machine lift up and down?

Yes, there is handle wheel to adjust the height of sealing head according to different bottle height.

Which do you recommend, steam heating or electric heating?

To save cost, electric heating is recommended, especially for small capacity soap mixing tank; Steam heating requires a steam generator, if client has steam generator, steam heating is recommended.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery