YUANYANG Bottle Sealing Machines for Industrial Mixers | Complete Packaging Solutions

Elevate Your Production Line with YUANYANG Bottle Sealing Machines for Industrial Mixers

As a global leader in industrial mixers and agitators, YUANYANG understands that the journey from product creation to market readiness demands precision at every step. While our vacuum homogenizers, emulsifying mixers, and high shear mixers craft the perfect formulations, the final touch—secure and professional packaging—is equally crucial. YUANYANG's advanced bottle sealing machines for industrial mixers are engineered to provide that impeccable finish, ensuring product integrity, extended shelf life, and a pristine brand presentation for your meticulously prepared products.

Since 2008, YUANYANG has focused on delivering not just mixing equipment, but complete production line solutions. Our sealing machines seamlessly integrate into your existing setup, representing a vital component of a fully optimized packaging process for diverse industries, from cosmetics and pharmaceuticals to food and chemicals.

Precision Sealing for Diverse Industrial Mixer Products

The versatility of YUANYANG's industrial mixers means you process a wide array of viscosities and product types. Our bottle sealing machines are designed with this diversity in mind, providing robust and reliable sealing for bottles, jars, and containers filled with everything from thin liquids to thick creams and gels. Whether it's an induction sealer for tamper-evident foil seals or a capping machine for screw caps, our equipment ensures a tight, secure closure that protects your product from contamination, leakage, and tampering. This precision is paramount for maintaining the quality and safety standards your customers expect from products processed by YUANYANG's high-performance mixers.

Seamless Integration & Turnkey Solutions

At YUANYANG, we pride ourselves on offering more than just standalone machines. Our expertise extends to providing comprehensive packaging solutions that complete your production line. Our bottle sealing machines for industrial mixers are designed to integrate flawlessly with our filling machines, capping machines, and labeling machines, creating a streamlined, efficient workflow. From initial consultation to one-stop installation support and free technical training, YUANYANG delivers a full suite of turnkey services. This means less hassle for you and a faster, smoother path to full operational capacity, maximizing your return on investment.

YUANYANG Quality & Compliance You Can Trust

Quality and reliability are at the core of YUANYANG's manufacturing philosophy. Our industrial equipment, including our bottle sealing machines, proudly carries multiple CE certifications. While CE certification is a safety and health mark, not solely a quality mark, it signifies our adherence to stringent European Union standards, ensuring our machinery meets essential safety, health, and environmental protection requirements. This commitment underscores our vision to become the best industrial mixer and agitator manufacturer in the world, providing equipment that you can trust for both performance and compliance.

Partner with YUANYANG for Optimized Packaging

Investing in a YUANYANG bottle sealing machine for industrial mixers means investing in efficiency, security, and peace of mind. Partner with us to optimize your packaging process and ensure your high-quality products leave your facility in perfectly sealed, market-ready condition. Explore our complete range of packaging solutions and discover how YUANYANG can elevate your entire production line. Visit yuanymachinery.com today to learn more.

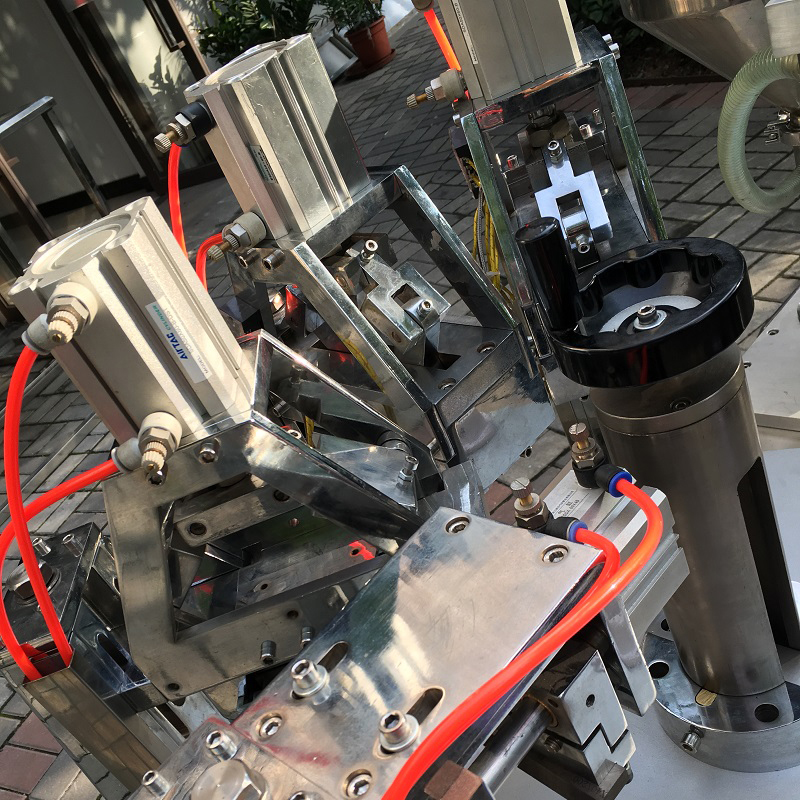

bottle sealing machine for industrial mixers Display

Can you customize the nozzle size to fit my different container?

Yes, we customize nozzle for clients according specific packages.

Can packing machinery be used for different film size?

The sachet packing machine for powders is suitable for different film width, but need to customize the bag-former for specific film width, then clients just need to replace the corresponding model for another film width.

Can you introduce the working process of the water filter?

One stage: raw water - raw water pump - sand filter - carbon filter - softener(optional) - salt tank - high pressure pump - reverse osmosis membrane system - one stage ro system storage tank

Two stage: one stage ro system storage tank - EDI system - EDI storage tank - two stage ro system storage tank - two stage ro water process - pure water pump - UV sterilizer - Finished pure water storage tank

Is the lid of the steel drum removable?

There are fixed lid, half open type and removable lid type.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery