Multi-Head Anti-Corrosion Liquid Filling Machine | Magnetic Pump Filler

Explore our multi-head anti-corrosion filling machine with magnetic pump technology. Ideal for chemical, water-based, and corrosive liquid filling lines.

- Enhance Your Chemical Liquid Production with a Multi-Head Anti-Corrosion Filling Machine

- Introduction: The Importance of Precision in Chemical Liquid Filling

- What Makes an Anti-Corrosion Filling Machine Essential?

- Built to Withstand Corrosive Liquids

- Magnetic Pump Technology for Superior Control

- Why Opt for a Multi-Head Design?

- Increased Efficiency and Speed

- Versatility in Filling Volumes

- Automated Production Line Integration

- Real-World Application: Chemical Manufacturer in Malaysia

- Client Overview

- The Solution We Provided

- Outcomes Achieved

- Why Magnetic Pump Technology Is Key

- High Precision and Efficiency

- Long-Lasting Durability

- Seamless Integration into Fully Automated Production Lines

- Key Advantages of Multi-Head Anti-Corrosion Filling Machines

- Conclusion: Boost Your Production with the Right Equipment

Enhance Your Chemical Liquid Production with a Multi-Head Anti-Corrosion Filling Machine

Introduction: The Importance of Precision in Chemical Liquid Filling

In industries where chemicals, disinfectants, or corrosive liquids are produced, precision and safety during the filling process are paramount. Standard filling machines often fall short when it comes to handling aggressive ingredients such as bleach, sanitizers, and alkali-based solutions. To solve this challenge, a multi-head anti-corrosion filling machine provides a highly efficient and reliable solution.

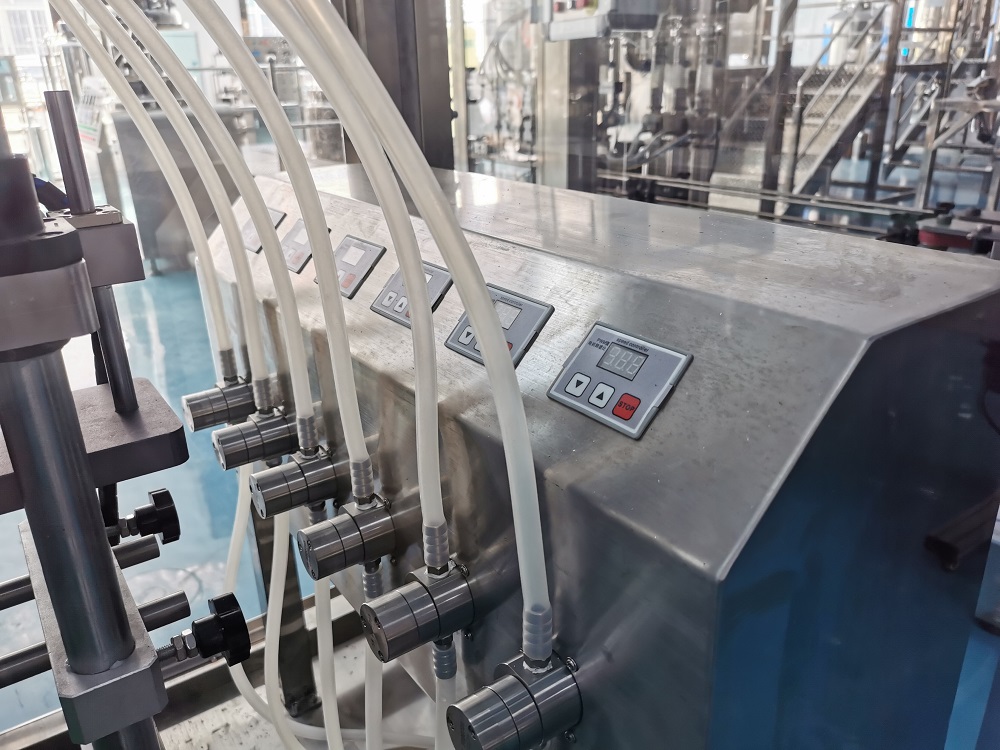

This machine, specifically designed for corrosive liquids, combines advanced magnetic pump filling technology with the robust durability of anti-corrosive materials to ensure consistent, precise filling. Whether it's a liquid filling machine or a water filling machine, this equipment is perfect for enhancing the speed and reliability of production lines in industries like chemicals, cosmetics, and pharmaceuticals.

What Makes an Anti-Corrosion Filling Machine Essential?

Built to Withstand Corrosive Liquids

An anti-corrosion filling machine is engineered with durable materials, such as PTFE, PVDF, PVC, and 316L stainless steel, to prevent degradation when exposed to corrosive substances. These materials ensure the machine's longevity, while also preventing contamination of sensitive liquids. This is a critical feature for industries dealing with chemicals like bleach, acids, or alkalis.

Magnetic Pump Technology for Superior Control

At the heart of the magnetic pump filling machine is a technology that allows for accurate, non-contact filling. The pump uses magnetic fields to drive the flow of liquids, eliminating the need for mechanical seals that can wear out or leak over time. This technology ensures that the machine operates smoothly without the risk of cross-contamination, making it ideal for industries requiring high hygiene standards.

Why Opt for a Multi-Head Design?

Increased Efficiency and Speed

A multi-head filling machine allows for multiple bottles to be filled simultaneously. With 4 to 12 heads, this equipment can significantly boost production speed. For example, a 6-head system can fill up to 1,500 bottles per hour, which is a major increase in output compared to traditional systems.

Versatility in Filling Volumes

Each head of the machine can be individually calibrated, making it suitable for various bottle sizes—from small containers of 100 ml to larger 5L bottles. This adaptability makes the anti-corrosion filling machine a versatile solution for diverse production needs.

Automated Production Line Integration

The multi-head design works seamlessly with other equipment, such as bottle unscramblers, capping machines, and labeling systems, to form a fully automated production line. This minimizes manual labor, reduces errors, and optimizes production efficiency.

Real-World Application: Chemical Manufacturer in Malaysia

Client Overview

One of our clients, a leading manufacturer of household chemical products in Malaysia, required an efficient solution to fill water-based bleach and toilet cleaner into HDPE bottles. Their main objectives were to improve production speed, ensure filling accuracy, and minimize labor costs.

The Solution We Provided

For this client, we supplied a GZ-AF6 model with 6 magnetic pump heads. The machine's specifications included:

-

Anti-corrosive PVDF and PVC components

-

PLC and touchscreen control system

-

Integrated automatic capping system

Outcomes Achieved

-

Filling speed: Approximately 1,500 bottles per hour

-

Precision: ±0.5% fill accuracy

-

Clean, drip-free operation: No spills or contamination

-

Labor reduction: Only 2 operators needed

The system not only met but exceeded their expectations, offering both speed and reliability in their production line.

Why Magnetic Pump Technology Is Key

High Precision and Efficiency

Magnetic pump technology offers more than just drip-free performance. It allows for highly accurate control over the flow rate, ensuring that each bottle is filled with the exact volume needed. This precision is especially important when filling liquids like bleach or other chemicals, where even small variances can affect product quality.

Long-Lasting Durability

With fewer moving parts than traditional filling machines, magnetic pumps have a longer service life and require less maintenance. This translates to cost savings over time, making it a smart investment for companies that want to reduce downtime and maintenance costs.

Seamless Integration into Fully Automated Production Lines

In today’s fast-paced production environment, efficiency and automation are critical. The multi-head anti-corrosion filling machine can be easily integrated into an automated production line, which can include:

-

Automatic bottle unscramblers

-

Filling machines

-

Capping systems

-

Labeling and packing machines

This integration reduces human intervention, speeds up production, and ensures consistency in the final product.

Key Advantages of Multi-Head Anti-Corrosion Filling Machines

-

Durable and corrosion-resistant construction for handling aggressive liquids

-

Multiple filling heads for higher throughput

-

Customizable filling volumes for different bottle sizes

-

Magnetic pump technology for clean, precise filling

-

PLC control system for easy operation and adjustment

-

Seamless integration with other automated production equipment

Conclusion: Boost Your Production with the Right Equipment

If your business deals with corrosive chemicals or water-like liquids, a multi-head anti-corrosion magnetic pump filling machine is an indispensable tool for improving both efficiency and precision. Designed for high-output environments, it ensures that your products are filled accurately, quickly, and safely.

Contact Guangzhou Mechanical Device Co., Ltd. today to learn how we can help you design and implement a tailored filling solution that suits your needs. Our team is here to support your growth and innovation.

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Semi Automatic Double Sides Labeling Machine

Can you add a date printer for the double-side labeling machine?

Yes, optional ribbon coding machine and inkjet printer, to print production date and batch number information on the label, to achieve labeling - coding integration.

Ink Jet Printer

What else can the bottle coding machine print others except date?

Yes, the date coding machine can print batch number, logo, product name, production date, expiration date, number, bar code, QR code, pictures, etc.

Cosmetic

What maintenance and support do you provide for the equipment?

We provide detailed equipment maintenance guides and offer regular maintenance services to ensure long-term optimal performance. Additionally, we offer quick-response after-sales technical support to resolve any unexpected issues.

Hydraulic Lift Vacuum Mixer

How do you pack for the cosmetic emulsifier?

The emulsifying equipment will be wrapped with film first, then packed with wooden case. The machine is well-protected during shipment.

FAQs

How is the quality?

We provide high-standard equipment. Quality is priority. People from Yuany always attach great importance to quality control from the beginning to the end. We support production inspection before shipment. And all machines will be tested and send you videos. You can also send your own packages/materials for rest-run after the machines are finished. Our factory has gained GMP,ISO,and CE Certificates.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery