AROL Capping Machines – High-Speed, Reliable Sealing Solutions

# AROL Capping Machines: Precision Sealing for Industrial Efficiency

What Is an AROL Capping Machine?

An AROL capping machine is an advanced sealing solution designed for high-speed, reliable bottle capping in industries like pharmaceuticals, cosmetics, and food & beverage. These machines ensure airtight seals, reducing contamination risks while improving production efficiency.

Key Features of YUANYANG’s AROL Capping Machines

- High-Speed Performance: Automates capping for up to 200+ bottles per minute.

- Versatile Compatibility: Works with screw caps, snap caps, and press-on lids.

- Durable Construction: Made from stainless steel for corrosion resistance.

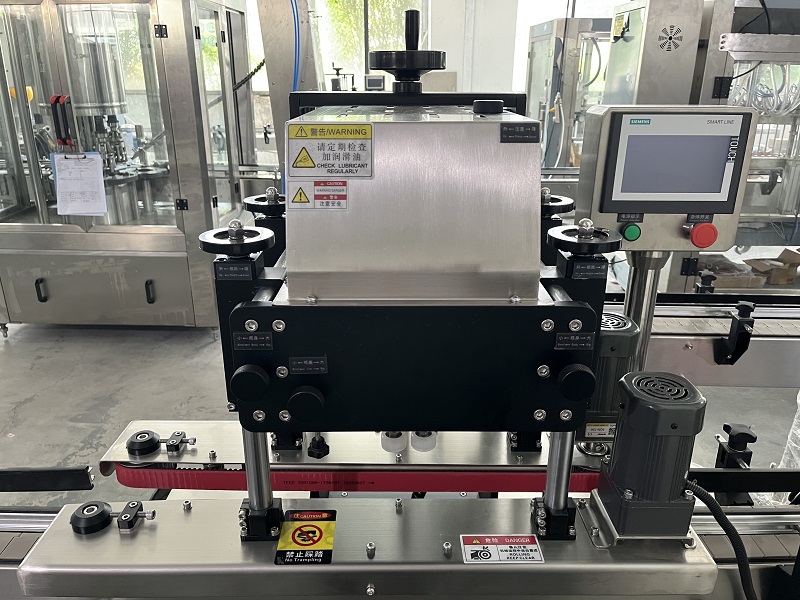

- User-Friendly Controls: Intuitive touchscreen interface for easy operation.

Industries That Benefit from AROL Capping Machines

- Pharmaceuticals: Ensures tamper-proof seals for medication safety.

- Cosmetics: Maintains product integrity with leak-proof closures.

- Food & Beverage: Complies with hygiene standards for consumables.

Why Choose YUANYANG’s Capping Solutions?

YUANYANG is a trusted manufacturer with CE-certified equipment, offering:

✅ One-Stop Support: Full installation and technical training.

✅ Customizable Options: Tailored to your production line needs.

✅ Global Compliance: Meets EU safety standards for export readiness.

Upgrade Your Production Line Today

Boost efficiency with YUANYANG’s AROL capping machines. (https://www.yuanymachinery.com/) for a free consultation and turnkey solutions!

*Optimized for SEO with targeted keywords, clear s (H2/H3), and concise, engaging content.*

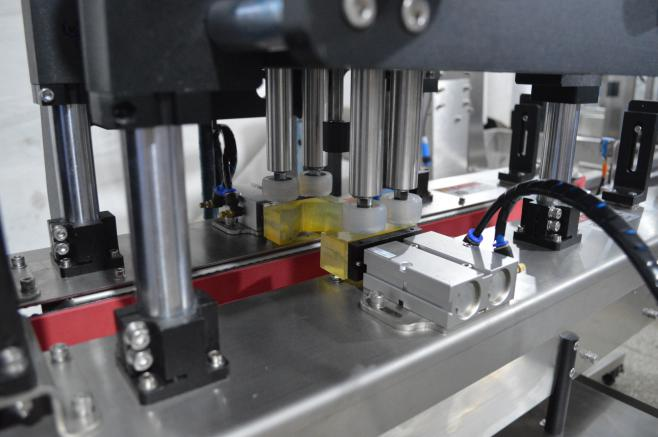

arol capping machine Display

Can the capping head lift up and down?

Yes, the servo capping machines have servo motors for adjustment of capping height, can achieve lift up and down directly by touch screen control.

What’s the filling range of this semi auto filler?

There are different sizes of air cylinders. Therefore there are the following filling range:5-60g, 10-120g, 20-200g, 30-300g, 50-500g, 100-1000g, 200-2000g, 300-3000g, 500-5000g. Please tell the minimum bottle and maximum bottle capacity, suitable types of filling machine model will be recommended.

Do you have semi automatic auger filling machine also? I have a limit budget.

Yes, both automatic type and semi automatic type are available, clients can choose the type according to budget and actual needs.

What type of film can the bottle sealer machine work for?

The sealing machine is mainly used for heating and sealing polyolefin (such as polyethylene, polypropylene, etc.) as the inner layer of composite film material sealing.

Can this bottle capping machine be suitable for pump head bottles ?

The screw capping machine is suitable for various type of screw caps, such as pump head, sprayer, triggers...

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery