Automatic Filling and Capping Machines | YUANYANG Industrial Solutions

Automatic Filling and Capping Machines for Industrial Excellence

Precision Filling for Every Industry

YUANYANG's automatic filling machines deliver unmatched accuracy for liquids, creams, and pastes. Our advanced technology ensures consistent fill levels, minimizing waste and maximizing productivity. Ideal for pharmaceuticals, cosmetics, and food industries.

High-Speed Capping Solutions

Pair your filling process with our robust capping machines for a complete packaging solution. From screw caps to snap lids, our machines handle diverse container types with speed and reliability, ensuring perfect seals every time.

Seamless Production Line Integration

Designed for easy integration with mixing equipment and labeling systems, our filling and capping machines create efficient, turnkey production lines. YUANYANG provides complete installation support and technical training.

CE-Certified Quality Assurance

All YUANYANG machines meet strict CE safety standards, giving you confidence in equipment performance and workplace safety. Our global clients trust our commitment to quality and innovation.

Custom Solutions for Your Needs

Whether you need small-batch flexibility or high-volume production, we offer customizable filling and capping solutions. Our engineering team tailors machines to your specific container types, viscosities, and output requirements.

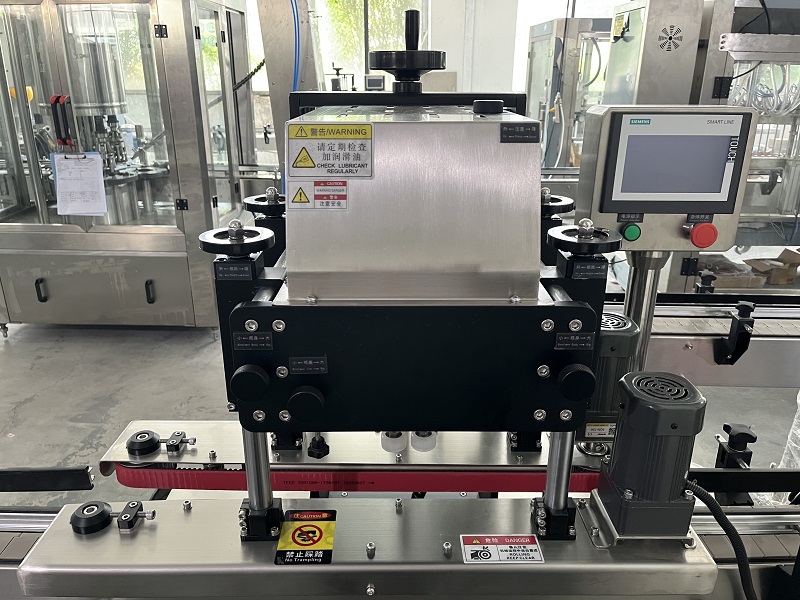

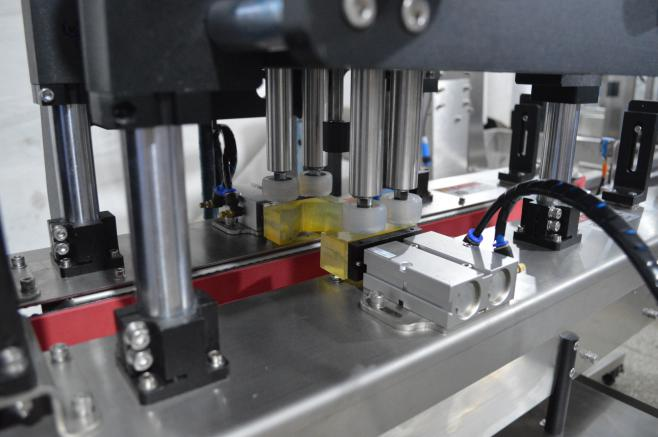

automatic filling and capping machine Display

Can I buy spare parts of heater tubes in case the heater burns?

Yes, we supply spare heating tubes. Client just remember the heater can not be operated without liquids in the jacket, otherwise, the heating tube will burn.

Do you provide operational training?

Yes, we provide detailed operational manuals and comprehensive training to ensure safe and efficient operation of the equipment.

Do you also provide liquid soap formula and technical training for a new user?

Yes, Yuany is experienced in liquid soap production for many years. We can provide professional training and teach face to face for clients. Don’t hesitate to contact us.

Can you add a mixing function for the tank with heater?

Sure, the cooling tank or heating tank can be customized with top mixing such as paddle, or frame, or scrapers. And client can choose a fixed speed 60rpm, or standard 0-60 rpm with speed adjustment, or customize other speed.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery