YUANYANG Bottle Screw Capping Machine

YUANYANG Bottle Screw Capping Machine

Overview

YUANYANG's bottle screw capping machine is engineered for stable, high-precision capping across industries such as cosmetics, pharmaceuticals, food & beverage, and chemicals. As a leading manufacturer of industrial mixers and complete production-line equipment since 2008, YUANYANG integrates robust mechanical design with user-friendly controls to deliver reliable performance in continuous production environments.

Key Features

Our bottle screw capping machine offers adjustable torque control, high-speed servo-driven cap feeders, and quick-change tooling for multiple cap sizes. Built with stainless steel contact parts and intuitive HMI, the capping unit minimizes downtime and ensures consistent seal integrity. CE-certified safety features and optional dust-proof or stainless models meet strict hygiene demands.

Integration & Compatibility

Designed for seamless line integration, the bottle screw capping machine pairs perfectly with YUANYANG’s vacuum homogenizers, emulsifying mixers, filling machines, labeling units, and sealing equipment. We provide turnkey project support—layout design, installation, and commissioning—so your production line operates efficiently from day one.

Applications

Ideal for bottles and containers made of glass, PET, HDPE and other materials, the capping machine handles varied cap types including screw, lug, and tamper-evident caps. Typical applications include bottled beverages, pharmaceutical vials, cosmetic containers, and industrial chemical packaging where repeatable torque and placement accuracy are critical.

Quality Assurance & Support

YUANYANG holds multiple CE certifications and follows strict quality control protocols during manufacturing. We offer free technical training, one-stop installation support, and responsive after-sales service. CE marks indicate compliance with EU safety and health directives; our focus remains on delivering reliable, safe equipment.

Why Choose YUANYANG

With a vision to be the world’s best industrial mixer and agitator manufacturer, YUANYANG pairs deep industry expertise with turnkey capabilities. Choose our bottle screw capping machine for precision, durability, and full-line compatibility supported by global service and practical operator training. Contact us at [email protected] or visit https://www.yuanymachinery.com/ to request a quote or technical consultation.

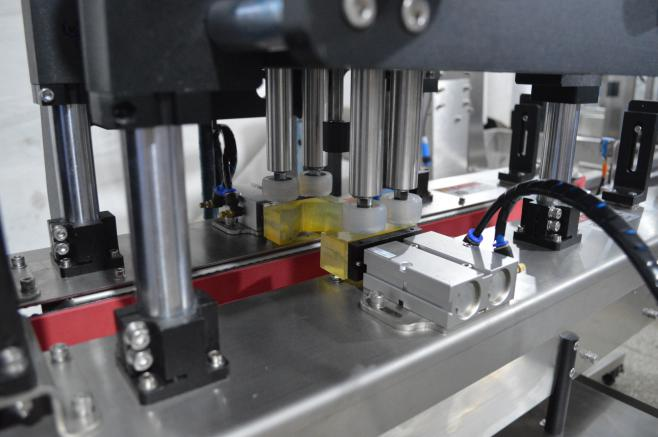

bottle screw capping machine Display

Are the machines easy to clean and maintain?

Absolutely, our equipment is designed for easy disassembly and cleaning, ideal for frequent maintenance.

What’s your advantages

We have over than 15 years of manufacturing experience for complete set of production line machines with professional team and technical staffs. Our professional solutions,details-focused services,customization capability,strict quality control process, fast and patient response,which wins the trust of various overseas customers. Yuany Machinery is always one of your first choice for win-win cooperation.

What’s the material of the mixer with agitator ?

Yes, all the tank mixers are made of stainless steel, and the standard contact part is made of ss316L, other parts ss304, which meet GMP standards and is CE proved.

Can you add a lid for the storage tank?

Yes, the lid can be added and customized. For example, with a central hole for overhead mixer, with a material hopper for adding powder or liquids.

Do you also provide liquid soap formula and technical training for a new user?

Yes, Yuany is experienced in liquid soap production for many years. We can provide professional training and teach face to face for clients. Don’t hesitate to contact us.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery