YUANYANG Industrial Homogenizers: Mastering the Homogenizer Process for Superior Results

YUANYANG Industrial Homogenizers: Mastering the Homogenizer Process for Superior Results

At YUANYANG, a leading manufacturer of industrial mixers and agitators since 2008, we understand that achieving product excellence hinges on precision. Our range of industrial homogenizers is meticulously engineered to master the critical homogenizer process, ensuring unparalleled consistency, stability, and quality for your diverse applications.

Unlocking Precision with YUANYANG Homogenizers

Homogenization is more than just mixing; it's the art of transforming raw materials into a uniformly dispersed and stable product. Our cutting-edge industrial mixers, including vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers, are designed to perform this vital task with utmost efficiency. Whether it's reducing particle size, creating stable emulsions, or achieving perfect suspensions, YUANYANG homogenizers deliver superior results every time, meeting the stringent demands of industries from cosmetics and pharmaceuticals to food and chemicals.

The Critical Homogenizer Process Explained

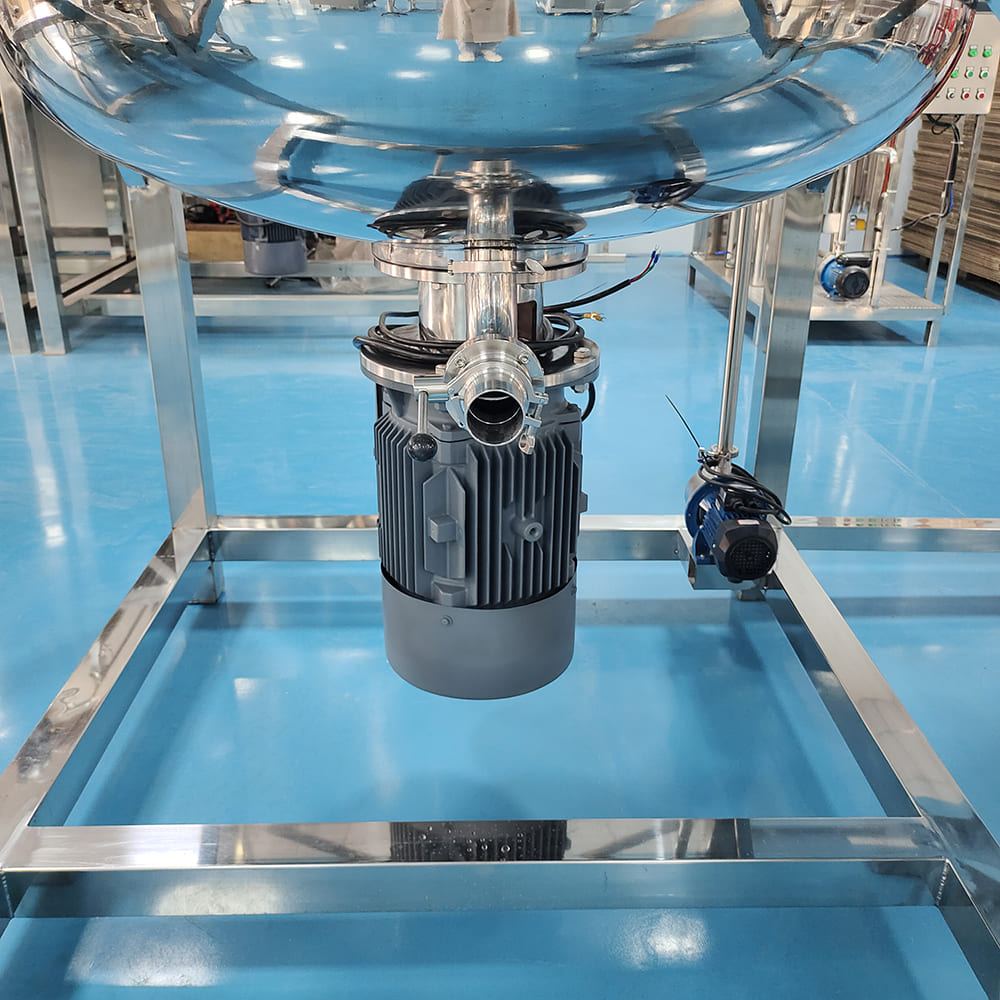

The core of our advanced equipment lies in its ability to execute a flawless homogenizer process. Our machines utilize powerful high-shear forces, often combined with vacuum technology, to finely disperse, emulsify, and blend ingredients. This mechanical action ensures that immiscible liquids are transformed into stable emulsions, solid particles are uniformly distributed, and air bubbles are efficiently removed, leading to a smooth, uniform product free from separation. This meticulous process is fundamental for product integrity, shelf-life, and sensory attributes, making our vacuum homogenizers indispensable for modern manufacturing.

Comprehensive Solutions for Diverse Industries

YUANYANG prides itself on being more than just an equipment supplier. Since 2008, we have focused on providing complete production line equipment. Beyond our core mixing solutions, our offerings extend to storage tanks, filling machines, capping machines, labeling machines, sealing machines, inkjet printers, and water treatment equipment. This comprehensive approach means we can provide free technical training and one-stop installation support, delivering a full set of turnkey services that streamline your operations and accelerate your time to market.

Why YUANYANG Stands Apart

As one of China's leading manufacturers, YUANYANG's commitment to quality and innovation is unwavering. Our industrial mixers are designed with user-friendliness and efficiency in mind, ensuring ease of operation and maintenance. We are proud to have obtained multiple CE certifications, affirming our dedication to international safety and health standards. Our vision is clear: to become the best industrial mixer and agitator manufacturer in the world, a goal we pursue by continuously delivering high-performance, reliable equipment and unparalleled customer support. Partner with YUANYANG for your homogenization needs and experience the difference that expertise and dedication make.

homogenizer process Display

Do you have a standing portable bottle sealer to be put directly after my automatic capping machine?

Yes, we have a vertical movable type lid sealer which can be directly put after capping machine as long as there is space for conveyor. The movable type can be used with conveyor directly.

Can you explain the heating principle? How does it achieve heating purpose?

The jacket tank transmits heat to the liquid through the principle of heat conduction, and the heat medium in circulation between the inner wall and the jacket is responsible for conducting heat and transferring the temperature of the jacket heat medium to the liquid product.

How does the powder transfer auger feeding machine convey materials?

It transports materials continuously through screw rotation by electric motor drive.

What capacity do you supply for this dry powder mixer?

The standard capacity of powder mixing tank is from 200L 500L 1000L 1500L 2000L. If clients need other capacity, just tell us to design.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery