Industrial Water Treatment Equipment

Industrial Water Treatment Equipment

Complete Water Treatment Solutions for Industry

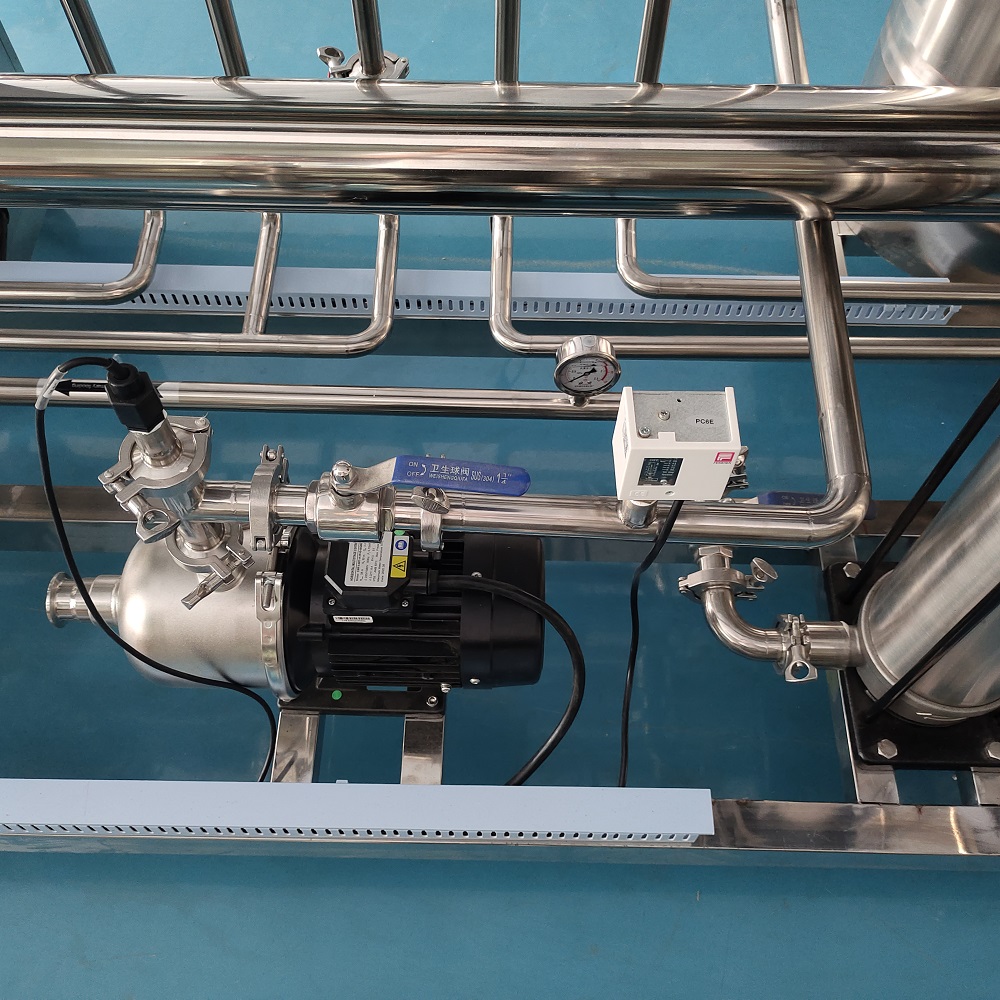

YUANYANG specializes in high-performance industrial water treatment equipment designed to meet rigorous purification needs. Our advanced systems ensure clean and safe water, supporting a wide range of industrial sectors including pharmaceuticals, cosmetics, and food processing.

Comprehensive Product Range

Our water treatment equipment covers every step in the filtration and purification process. From sediment filters and activated carbon filters to reverse osmosis systems and UV sterilizers, YUANYANG delivers complete solutions for water quality management. Each unit is built for durability and efficiency, helping you maintain consistent production standards.

Custom Turnkey Services for Seamless Integration

YUANYANG provides not only world-class equipment, but also expert installation and technical training. Our turnkey support includes custom system design, setup, and on-site training, ensuring smooth operation and minimal downtime. Benefit from our years of experience and robust after-sales assistance.

Commitment to Compliance and Quality

All our industrial water treatment equipment is manufactured according to strict international standards. With several CE certifications, YUANYANG commits to delivering reliable and globally compliant solutions focused on user safety and operational efficiency.

Why Choose YUANYANG for Your Water Treatment Needs

Partnering with YUANYANG means choosing a trusted China-based leader with a proven track record since 2008. Enjoy superior equipment, professional service, and complete support—all from one reputable supplier. Experience world-class industrial water treatment equipment designed to power your success.

industrial water treatment equipment Display

What types bottles are suitable for this label dispenser?

It is suitable for single side and double side labeling of flat bottles, round bottles and square bottles, such as shampoo, laundry detergent flat bottles, lubricating oil flat bottles, hand sanitizer round bottles and other double side labeling, both sides of the same labeling, double labeling improves production efficiency, and is widely used in daily chemical, cosmetics, petrochemical, pharmaceutical and other industries.

Is the powder screening machine used for detergent powder?

Yes, this can be used for detergent powder. It is a detergent powder screening machine.

Can I use city water to produce liquid detergent?

As you know, water takes 70-99% proportion of raw materials for liquid detergent production. So the quality of water is quite important to produce qualified liquid cleaning products. The raw water should be treated before taking into tank.

Can the capping head lift up and down?

Yes, the servo capping machines have servo motors for adjustment of capping height, can achieve lift up and down directly by touch screen control.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery