Liquid Soap Machines for Sale | YUANYANG

# Liquid Soap Making Machines for Sale

YUANYANG offers a comprehensive range of liquid soap making machines designed for efficient and high-quality production. We provide complete turnkey solutions, from mixing to packaging.

High-Performance Mixing Solutions

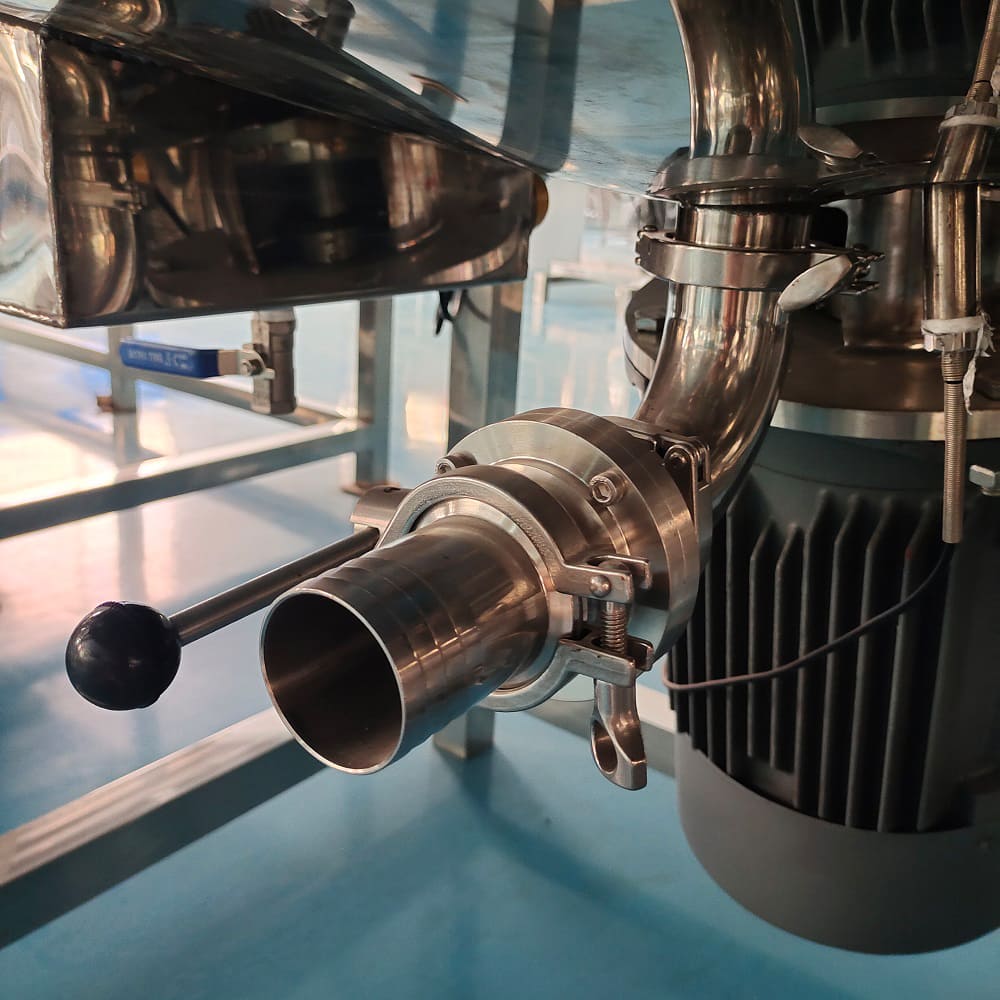

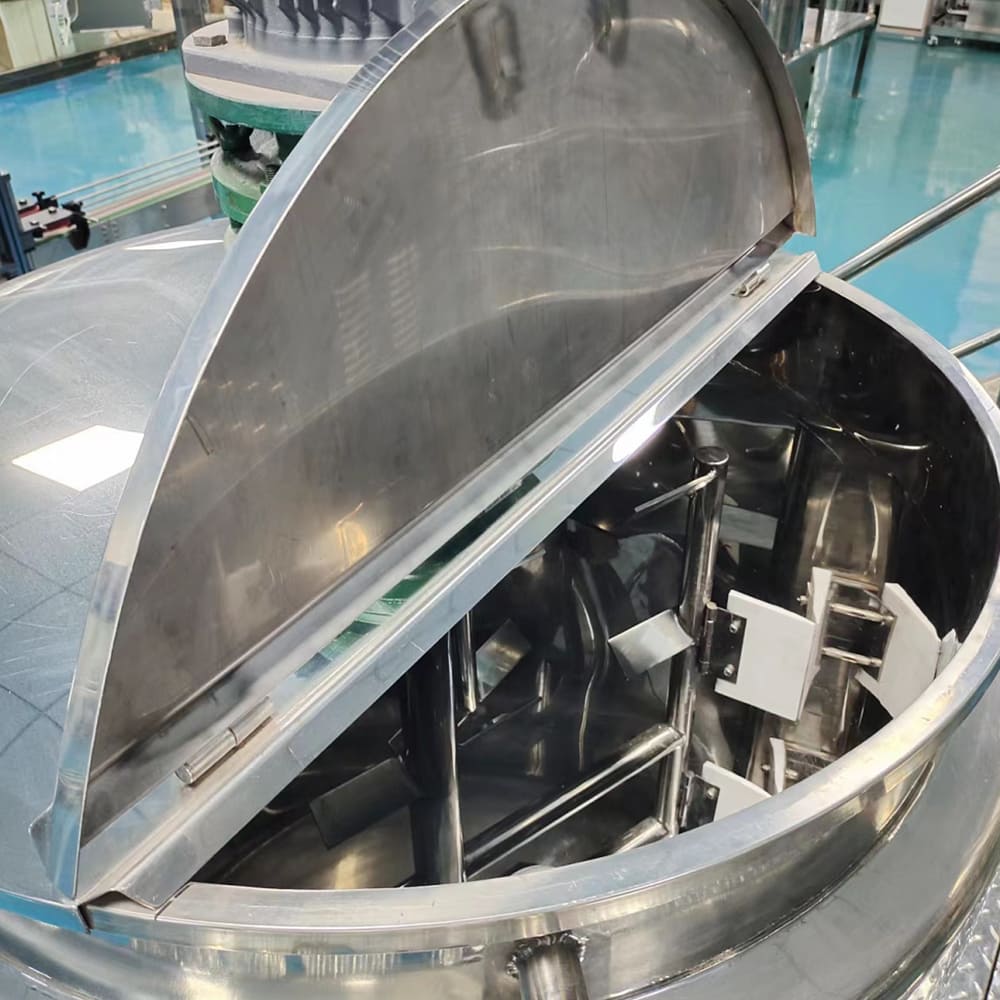

Our Liquid Soap Making Machines utilize advanced vacuum homogenizer mixers and vacuum emulsifying mixers, ensuring consistent and smooth soap formulations. These machines are built for durability and optimal performance, minimizing production downtime.

Complete Production Line Equipment

Beyond just mixing, we supply a complete liquid soap production line, including storage tanks, filling, capping, labeling, sealing, and coding machines. This streamlines your operations and boosts efficiency.

Turnkey Solutions & Support

YUANYANG provides comprehensive support, including free technical training and installation services for a seamless transition to your new production line. Our one-stop solution simplifies the process and minimizes complications.

Quality & Certification

All our Liquid Soap Making Machines are CE certified, meeting European safety and health standards. We prioritize quality and reliability in all our equipment, delivering exceptional value to our clients.

About YUANYANG

Established in 2008, YUANYANG is a leading manufacturer of industrial mixers and blenders in China. We are dedicated to providing innovative and reliable equipment for various industries, backed by our commitment to exceptional customer service. Contact us today to discuss your liquid soap production needs.

Liquid Soap Making Machine for Sale Display

I don’t come to the company, how can I learn the machines?

We provide video & manual instructions of the machines you purchase and online service,as well as face-to-face teaching. Any questions or concerns,please feel free to contact our customer service for free information. If you come to the company,our technical staff will teach you hand by hand.

Can the liquid filler be delivered by air?

If clients need it in a hurry, just choose to delivery by air. The desktop cream filling machine is not big, can arrange international express to pick-up the package. In order to save cost, client can choose by sea, which is much slower.

Can you explain the different between one stage and two stage of reverse osmosis water treatment?

The main different is the conductivity of water to be produced.

One stage≤10μs/cm, two stage around 2-3μs/cm, EDI≤0.5μs.cm

What’s the operation process?

Operation process: put the bottle on track- > step on the foot switch - > automatically taking the bottle in - > Automatically labeling - > Automatically taking the labeled bottle out.

What quality control measures are in place?

The equipment features strict parameter control during the production process to ensure that the final product meets the desired quality.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery