Efficient Jar Labeling Machines

YUANYANG Jar Labeling Machines: Precision, Speed, and Reliability

Versatile Solutions for Every Jar Labeling Need

YUANYANG’s jar labeling machines offer unmatched accuracy and flexibility, perfectly suited for a wide range of jar sizes and materials. Whether you’re labeling food jars, cosmetic bottles, or chemical containers, our equipment ensures consistently aligned, wrinkle-free labels for a High Quality shelf appearance.

Seamless Integration with Your Production Line

Our jar labeling machines are designed for easy integration with existing production lines. Featuring touch-screen controls and adaptive settings, they enable fast changeovers between different jar shapes and label types. YUANYANG ensures that automation fits seamlessly into your process, minimizing downtime and maximizing throughput.

Advanced Technology for Precision and Efficiency

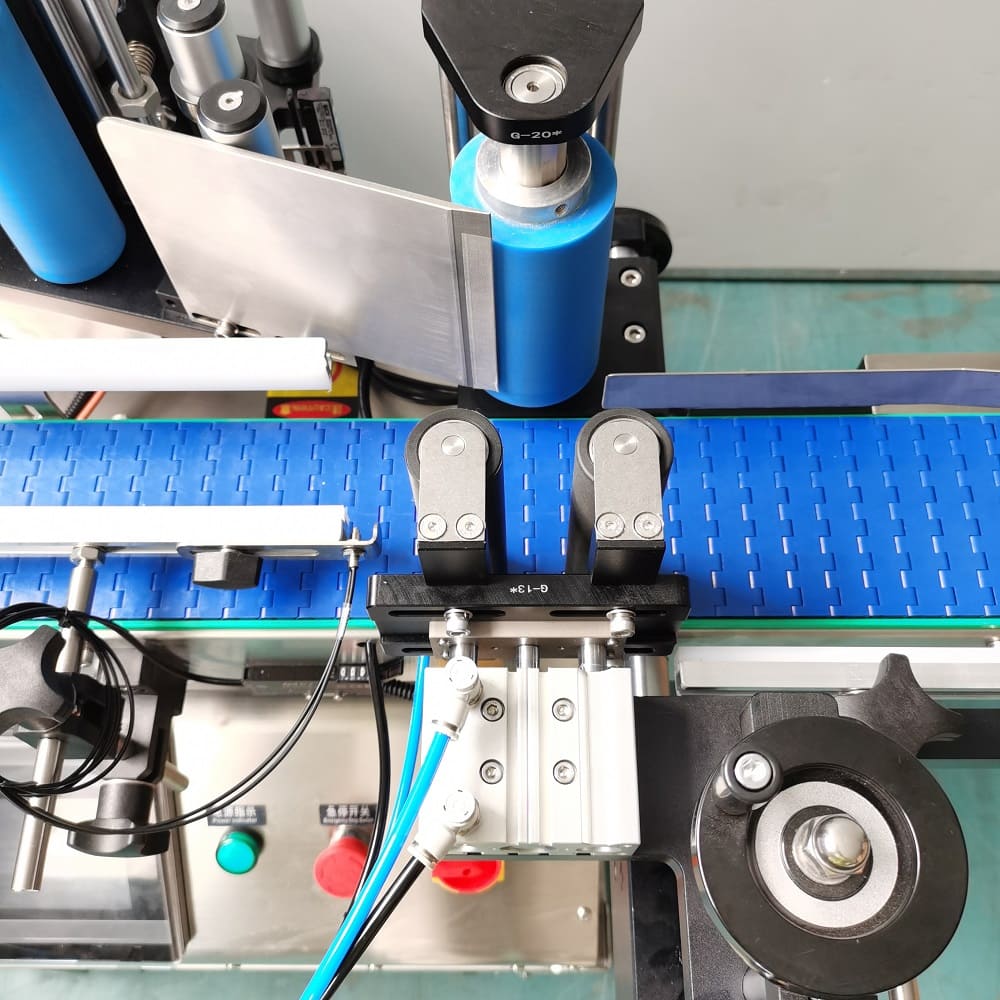

Experience efficient labeling with advanced sensors, high-speed motors, and precise applicators. YUANYANG jar labeling machines guarantee that every label is applied smoothly, with exact placement and reduced waste. This leads to significant time and cost savings for your operations.

Complete Turnkey and After-Sales Support

As a leading industrial solutions provider, YUANYANG offers not just machinery, but comprehensive support—free technical training, fast installation, and turnkey service from start to finish. Our CE-certified jar labeling machines come with strong after-sales support, ensuring reliability and peace of mind for global manufacturers.

Why Choose YUANYANG Jar Labeling Machines?

- Expertise Since 2008: Trusted manufacturer and supplier in complete production line machinery.

- One-stop Service: From mixers to packaging machines, streamline your entire workflow with YUANYANG.

- International Standards: Our CE certifications ensure compliance for global markets.

Upgrade your production with YUANYANG’s high-performance jar labeling machine solutions—engineered for efficiency, built for success.

jar labeling machine Display

Do you support international shipping and installation?

Yes, we provide global delivery services and offer international installation and commissioning services to ensure you can smoothly use the equipment for production.

What kind of liquids does this liquid bottling machine can fill?

It can fill various liquids products, such shampoo, cream, conditioner, detergent, lotion, sauce, and so on. The materials must be easy to flow down for this cream filler machine. For too viscous paste, pressurized filling machine or hot filling machine will be recommended based on materials. Please send your materials to check.

Is the speed adjustable with VFD?

The chemical mixer tank is often with frequency converter. But some clients may just need a fixed speed. So we customize upon requirements.

Why water pot and oil pot are needed?

The combination of water pot and oil pot plays a crucial role for cosmetic production equipment, which ensure the stability of the emulsification process and product quality through pretreatment and precise control each phase materials.

⦁ Pretreatment

The water pot and oil are equipped with heating and dispersing function. Each phase can be dissolved,dispersed,heated before entering into the main emulsifying equipment. The pretreatment improves emulsification efficiency, reduces unnecessary mixing problems, and ensures that the material is in the best condition during emulsification

⦁ Precise control

Each phase is with a separated pot. Through the precise control system of water pot and oil pot, the materials can be added to the emulsion pot according to the preset ratio and speed, to ensure the uniformity and stability of the mixing process. This precise control helps to produce a high quality, consistent product.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery