YUANYANG Inline Sealing Machines: Precision & Efficiency for Your Mixer Production Line

YUANYANG Inline Sealing Machines: Precision & Efficiency for Your Mixer Production Line

At YUANYANG, we understand that a high-quality industrial mixer is only part of the equation for a successful product. The final presentation and integrity of your product hinge on efficient and reliable packaging. As a leading manufacturer of industrial mixers and agitators since 2008, YUANYANG is proud to offer advanced inline sealing machines for mixer production lines, designed to provide the in precision, speed, and product security. From vacuum homogenizers to high shear mixers, our comprehensive solutions ensure your products are perfectly sealed and ready for market.

Seamless Integration for Optimal Performance

Our expertise extends beyond just mixing equipment. YUANYANG is dedicated to providing complete production line solutions. Our inline sealing machines are engineered for flawless integration within your existing or new YUANYANG setup, working in harmony with our filling machines, capping machines, and labeling machines. This seamless synergy minimizes downtime, optimizes workflow, and ensures a continuous, high-speed operation for packaging products processed by your vacuum emulsifying mixers or other specialized vacuum mixers. Experience a truly automated and efficient packaging stage that complements your production output perfectly.

Advanced Sealing Technology You Can Trust

YUANYANG's inline sealing machines are built with robust materials and cutting-edge technology to meet the stringent demands of industrial environments. We focus on delivering precise, consistent seals that maintain product freshness, prevent leakage, and uphold YUANYANG's reputation. Whether you require induction sealing, heat sealing, or other specialized sealing methods, our machines are designed for adaptability and user-friendliness, guaranteeing reliable performance shift after shift. You invest in quality when you choose YUANYANG, ensuring your valuable mixer-produced goods are protected.

YUANYANG's Commitment: Quality, Support, and Global Vision

Your peace of mind is our priority. YUANYANG has obtained multiple CE certifications, affirming our commitment to safety and health standards. When you choose our inline sealing machine for mixer production line, you're not just getting a machine; you're gaining a partner. We offer free technical training and one-stop installation support, providing a full set of turnkey services to get your line up and running smoothly. Our vision is to become the best industrial mixer and agitator manufacturer in the world, and that commitment extends to every piece of equipment we provide, ensuring top-tier quality from mixing to final seal.

Why Choose YUANYANG for Your Sealing Needs?

Choosing YUANYANG means partnering with a seasoned expert who understands the entire lifecycle of industrial production. Our proven track record since 2008, combined with our comprehensive offering of mixing equipment, storage tanks, and complete packaging solutions, makes us an unparalleled choice. Elevate your production line's efficiency, reduce operational costs, and secure your product integrity with YUANYANG's reliable, CE-certified inline sealing machines. Visit https://www.yuanymachinery.com/ to explore our full range of solutions and discover how we can transform your production process.

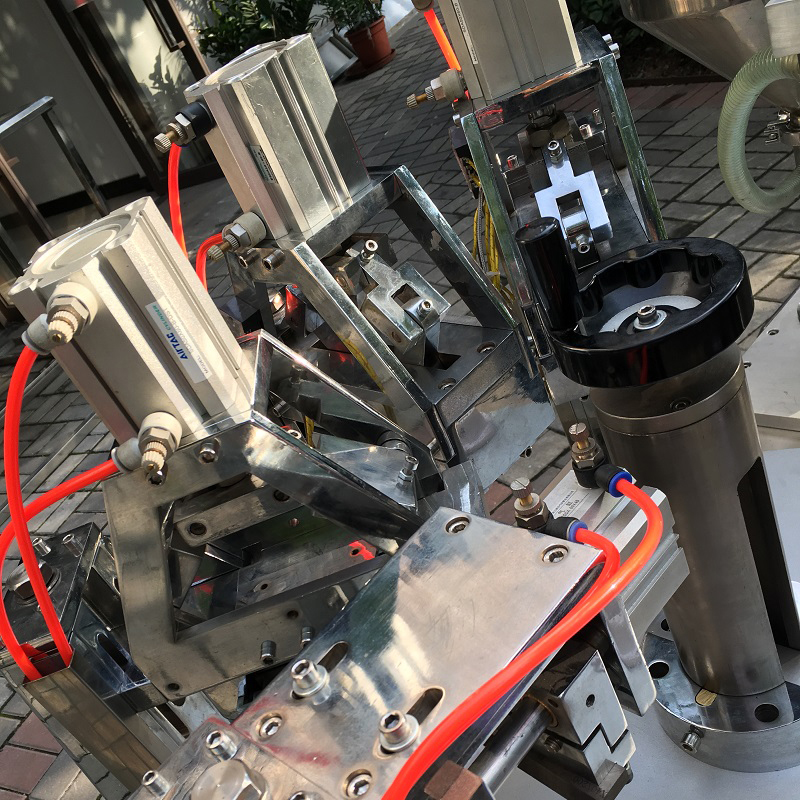

inline sealing machine for mixer production line Display

Can the dater printer spray all directions?

Yes, the spraying nozzle of the expiry date printer can be adjusted to all directions.

Does the jacket melting tank have temperature regulator?

Yes, the heated tank is with control panel, there is temperature display. The tank bottom is inserted a temperature probe. We can set the targeted temperature also.

Can the lid of this cosmetic cream mixing tank be open and lift up?

Yes, the cover of the sterile cosmetic mixing tank can be open and lift up by hydraulic system. What’s more, the main mixing tank can also tilt down to discharge

What type of film is the automatic packing machine suitable for?

The film materials include polypropylene film, polyethylene film, polyester film, nylon film and aluminum foil film and so on.

Can it close glass bottles?

As long as the glass bottle has screw cap, the capping machine can close its cap, although the machine is often called plastic capping machine.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery