Stainless Steel Mixing Tank Solutions by YUANYANG

Stainless Steel Mixing Tank Solutions by YUANYANG

Overview & Expertise

YUANYANG is a leading Chinese manufacturer of industrial mixers and agitators, offering high-performance stainless steel mixing tanks engineered for cosmetics, pharmaceuticals, food and chemical industries. With experience since 2008, our product range complements vacuum homogenizers, vacuum emulsifying mixers, and high shear mixers to provide integrated production lines.

Design & Materials

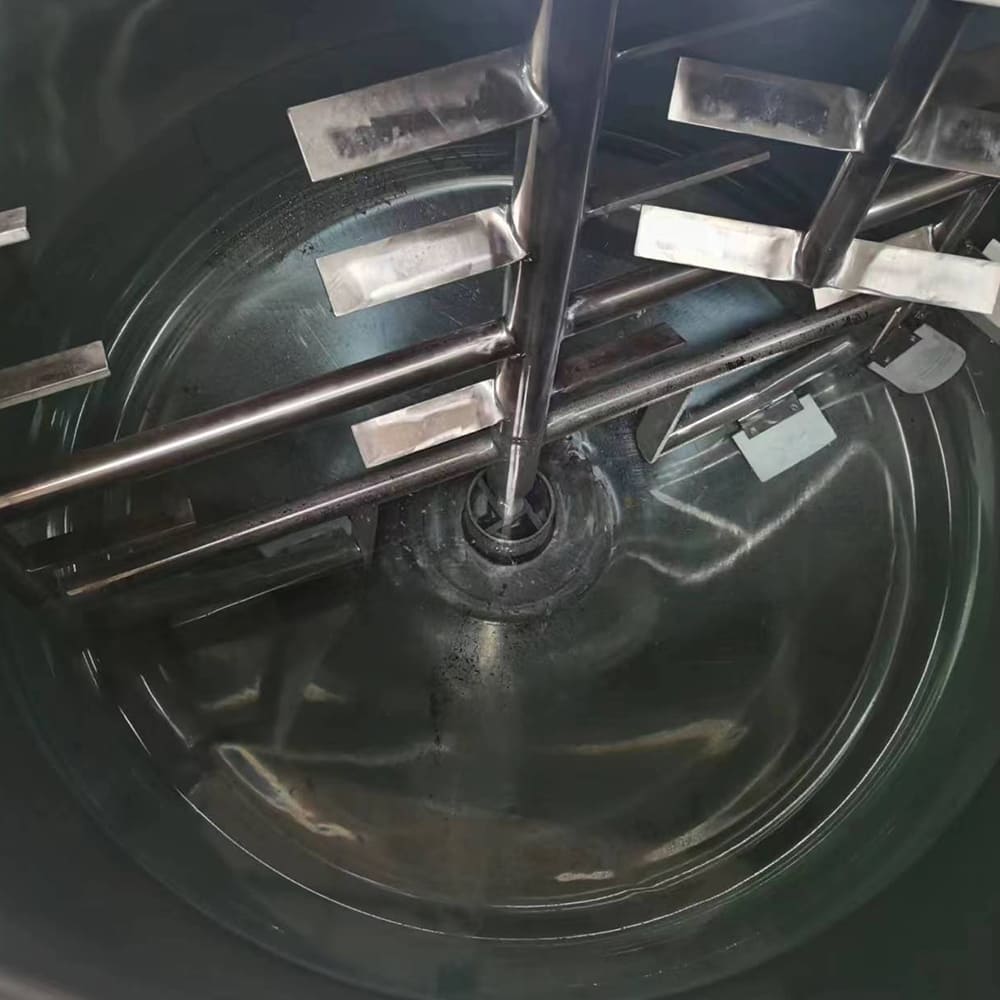

Our stainless steel mixing tank designs prioritize sanitary construction, corrosion resistance and GMP compliance. We use 304/316L stainless steel, polished interiors, and pressure- or jacketed-options for heating/cooling. Features such as removable shafts, CIP-ready fittings, and ASME-compatible welds enhance cleanliness and long-term reliability.

Applications & Performance

YUANYANG stainless steel mixing tanks are ideal for high-viscosity emulsions, dispersions, dissolution and long-term storage. Paired with vacuum emulsifying mixers or high shear units, they improve product uniformity, reduce air entrainment and speed up batch times, supporting cosmetics, food, chemical and pharmaceutical production requirements.

Customization & Integration

We offer tailored tank sizes, impeller types, heating/cooling jackets and instrumentation to match process needs. Our team designs turnkey solutions combining mixing equipment, storage tanks, filling, capping, labeling, sealing and water treatment so you receive a full production line ready for installation.

Service, Certification & Support

YUANYANG provides free technical training, one-stop installation support, and lifetime after-sales guidance. Our products carry multiple CE certifications for market access in the EU. For inquiries, contact [email protected] or visit https://www.yuanymachinery.com/ to discuss turnkey stainless steel mixing tank solutions.

stainless steel mixing tank Display

Can you add load cell system also for the liquid detergent making machine?

Yes, we add load cell upon requirements. Each mixer with 3 sets of load cell, and signal box, and display panel.

Is the material hopper of the powder dispenser machine openable?

Yes, the visual hopper can be easy open and disassembled for easy cleaning and parts replacement.

Can this capping machine for bottles be connected with filling machine,or labeling machine?

Yes, if client already has an old automatic labeling machine, just tell the conveyor height, we will customize our capping machine height.

Does the chemical mixer tank has jacket?

Yes, the liquid mixing machine with homogenizer is with jacket. Normally there are double jackets, one is for heating or cooling, the other is for insulation and protection. There is also single layer type. Clients can tell us specific function or consult us for recommendation.

I don’t need homogenizer, can you reduce it?

Yes, the homogenizer is an optional function, whether clients need it depends on your own products.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery