Ultimate Guide to Filling Machine 2026 : Application & Selection

Select the perfect filling machine with YUANYANG. Get expert guidance, CE-certified quality, and full turnkey support.

- Introduction: The Heart of Modern Packaging

- What is a Filling Machine?

- How Does a Filling Machine Work? Understanding the Mechanics

- Key Types of Filling Machines and Their Applications

- Liquid Filling Machines

- Powder Filling Machines

- Solid & Granular Filling Machines

- Specialized Systems

- Industries Revolutionized by Filling Machines

- Food and Beverage

- Pharmaceutical

- Cosmetic

- Chemical

- Benefits of Integrating a Filling Machine into Your Operations

- Choosing the Right Filling Machine: A Comprehensive Guide

- Installation, Operation, and Maintenance Tips

- Future Trends in Filling Machine Technology

- About us

- Conclusion

- FAQ

- What is the primary function of a filling machine?

- What are the main types of filling machines based on product type?

- How do liquid filling machines differ from powder filling machines?

- What industries heavily rely on filling machines?

- What factors should I consider when selecting a filling machine?

- Can filling machines handle different container sizes?

- What are the benefits of automated filling machines?

- How often should a filling machine be cleaned and maintained?

- References

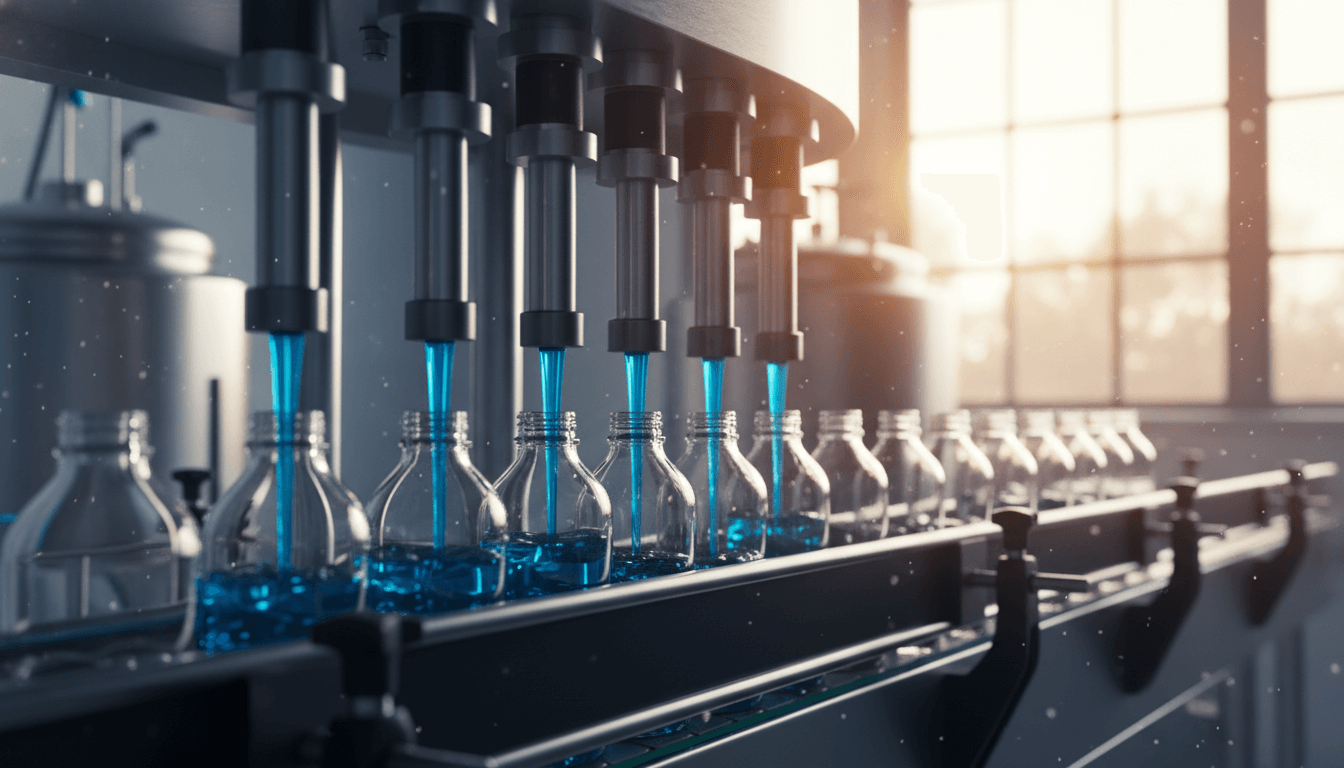

Introduction: The Heart of Modern Packaging

In the fast-paced world of manufacturing, the difference between profit and loss often comes down to how efficiently your production line runs. The filling machine is key to keeping this busy area running smoothly, making sure products are packaged quickly, accurately, and consistently. Pharmaceutical startups have to be able to fill thousands of vials of life-saving vaccines, and large-scale beverage companies have to be able to bottle mineral water. Either way, the filling process has to be reliable.

These machines are critical all over the world. Mordor Intelligence says the global filling machines market was worth about $7.95 billion in 2025, and they're predicting it'll reach almost $9.93 billion by 2030. This growth is driven by an increase in demand from the pharmaceutical and food industries, where precision and hygiene are crucial. This guide is a great resource for understanding filling machine technology. It helps manufacturers deal with the tricky parts of selection, operation, and maintenance.

What is a Filling Machine?

A filling machine is a special piece of industrial equipment that puts an exact amount of product into a container, like a bottle, pouch, tube, or can. Its main goal is to automate the packaging process, replacing manual labor to increase throughput and reduce waste.

While they're usually thought of as being used with liquids, these machines can actually do a lot more. They're designed to handle a wide range of product states:

· Liquids: From water and juices to viscous oils and syrups.

· Powders: Including flour, spices, and pharmaceutical formulations.

· Granules: Such as coffee beans, seeds, and fertilizers.

· Pastes & Creams: Cosmetic lotions, peanut butter, and industrial greases.

· Solids: Tablets, capsules, and even whole vegetables in canning lines.

How Does a Filling Machine Work? Understanding the Mechanics

A filling machine is basically three things: it measures, it dispenses, and it contains. The way it works varies depending on the product, but the workflow is pretty much the same.

1. Container Handling: Bottles or containers are moved into position, typically via a conveyor belt or a rotary star wheel.

2. Product Measurement: The machine isolates a specific amount of product. This is achieved through various mechanisms:

o Piston Fillers: A piston draws product into a cylinder and pushes it into the container (volume-based).

o Augers: A rotating screw forces powder through a funnel (volume/time-based).

o Flow Meters/Pumps: Electronic sensors measure the flow rate to determine volume.

o Net Weight Systems: Scales weigh the container before and during filling to ensure exact mass.

3. Dispensing: Nozzles descend or open to release the product into the container. Advanced nozzles are designed to prevent drips, foaming, or splashing.

4. Control Systems: Modern machines use PLCs (Programmable Logic Controllers) to manage timing, speed, and fill levels. Operators can adjust parameters based on time, weight, or volume to ensure consistency.

Key Types of Filling Machines and Their Applications

Picking the right machine depends entirely on the product's physical characteristics. Here's a rundown of the main categories:

Liquid Filling Machines

· Gravity Fillers: Ideal for thin liquids such as water and vinegar. The liquid is pulled into the container by gravity until it reaches a specific level.

· Piston Fillers: They're perfect for thick, viscous products like sauces, honey, or shampoos. They are ideal for extremely precise measurements of dense liquids.

· Overflow Fillers: These are unique machines that fill every bottle to the exact same visual level, no matter what minor bottle inconsistencies might be present. It's perfect for clear containers in the cosmetic and beverage industries.

Pump Fillers: These machines use gear or lobe pumps and can handle various viscosities, making them highly effective.

Powder Filling Machines

· Auger Fillers: This is the standard for fine powders like talc or flour. A screw mechanism dispenses the product with high precision.

· Vibratory Fillers: Use vibration to move the granular stuff (like salt or seeds) into a weigh bucket before dumping them into the package.

A powder filling machine can enhance your production line's performance.Integrating a powder filling machine can boost your production efficiency, streamlining the process and ensuring consistency in every batch.

Solid & Granular Filling Machines

· Volumetric Cup Fillers: Use pre-sized cups to easily measure free-flowing grains like rice or beans.

· Multi-Head Weighers: We've got some high-tech systems that calculate the best combination of weight buckets to achieve the target weight with almost no waste. You'll often see it on snack food packaging.

· Capsule Filling Machines: These machines are key in the pharmaceutical industry. They line up empty capsules, fill them with powder or granules, and seal them shut.

Specialized Systems

· Vertical Form Fill Seal (VFFS): It makes a bag out of a roll of film, fills it, and seals it. It's great for chips and other snacks.

· Aseptic Filling Lines: These machines are designed for sterile products (dairy, medical), and they operate in a sterile environment to extend shelf life without preservatives.

Industries Revolutionized by Filling Machines

Food and Beverage

This is the largest sector for filling equipment. IMARC Group data indicates that the food and beverage industry holds approximately 40% of the market share. Applications range from high-speed rotary fillers for soft drinks to gentle piston fillers for chunky salsas.

Pharmaceutical

Accuracy is a matter of life and death here. Machines must meet strict GMP (Good Manufacturing Practice) standards. Applications include sterile vial filling for vaccines, high-speed capsule filling, and precise syrup bottling.

Cosmetic

Aesthetics are key. Cosmetic fillers handle diverse textures—from watery toners to thick clay masks—often utilizing overflow fillers to ensure shelf appeal through consistent fill levels.

Chemical

Durability is the focus. Machines in this sector are built with anti-corrosive materials (like HDPE or titanium) to handle bleaches, acids, paints, and solvents without degrading.

Benefits of Integrating a Filling Machine into Your Operations

| Benefit | Description | Impact |

|---|---|---|

| Enhanced Efficiency | Automated filling machines can operate 24/7 without fatigue, greatly increasing output. | Increased productivity by up to 40% compared to semi-automated or manual processes. |

| Superior Accuracy | Automated systems maintain precise fill levels, reducing product giveaway (overfilling). | Reduced waste of raw materials, with accuracy maintained within ±0.5% or better. |

| Cost Reduction | While the initial investment is higher, labor costs are significantly reduced with automation. | Up to 50% reduction in labor costs, leading to long-term savings and a faster return on investment. |

| Improved Hygiene | Automated filling minimizes human contact, reducing contamination risks. | Enhanced product safety and quality, especially with machines equipped with CIP (Clean-In-Place) systems. |

| Scalability | Modular machines allow for adding more filling heads as production demand increases. | Flexible scalability to meet growing production needs without significant additional investment. |

Choosing the Right Filling Machine: A Comprehensive Guide

To select the perfect machine, consider these six critical factors:

1. Product Characteristics: Is it a liquid, powder, or solid? What's the viscosity? Does it foam? For example, foaming liquids need bottom-up filling nozzles.

2. Container Type: Glass requires gentle handling; plastic pouches need gripping mechanisms. The opening size determines the nozzle diameter.

3. Production Speed: Do you need 10 bottles per minute (BPM) or 500? This will determine if you need a semi-automatic single-head filler or a high-speed rotary monoblock.

4. Accuracy Requirements: High-value products—like perfume and pharmaceuticals—make high-precision weigh-fillers worth the cost. Low-cost bulk items may only need volumetric filling.

5. Budget & Space: When you're figuring out the cost of the machine, don't forget to add in the installation, utilities (like compressed air and power), and floor space.

6. Sanitation Standards: In order to comply with the regulations, food and pharmaceutical manufacturers must use stainless steel 316 construction and easy-clean designs.

Installation, Operation, and Maintenance Tips

· Installation: Make sure you've got a solid base to avoid any wobbling that could mess with your accuracy. Make sure the power and air supply are compatible with the machine's specifications.

· Calibration: Be sure to calibrate your weight scales and flow meters on the regular. A 1% deviation can end up costing thousands of dollars a year in lost product.

· Cleaning: Make sure you follow the cleaning schedule. For food/pharma, this usually means daily sanitization. We highly recommend automated CIP systems for liquid fillers.

· Preventive Maintenance: Replace wear parts like O-rings, gaskets, and pump seals before they fail. Make sure you always have a good supply of the most important spare parts on hand.

Future Trends in Filling Machine Technology

As we move toward 2030, the industry is shifting toward "Smart Packaging." Mordor Intelligence says that the rise of aseptic systems and sustainability are key drivers. The anti-corrosion liquid filling machine is already embracing some of these trends, offering higher efficiency, eco-friendly material compatibility, and quick changeover for diverse production needs. The liquid filling machine continues to evolve, and the multi-head anti-corrosion liquid filling machine is already embracing some of these trends, offering higher efficiency, eco-friendly material compatibility, and quick changeover for diverse production needs.

· IoT & Predictive Maintenance: Smart machines with sensors can predict when a motor is about to fail, and they'll alert operators and prevent unplanned downtime.

· Sustainability: They're making new machines that are designed to handle eco-friendly materials (like thinner plastics or recycled glass) and to reduce energy and water consumption during cleaning cycles.

· Flexibility: The demand for "SKU proliferation" means machines must change over from one bottle size to another in minutes, not hours. Tool-less changeover parts are becoming standard these days.

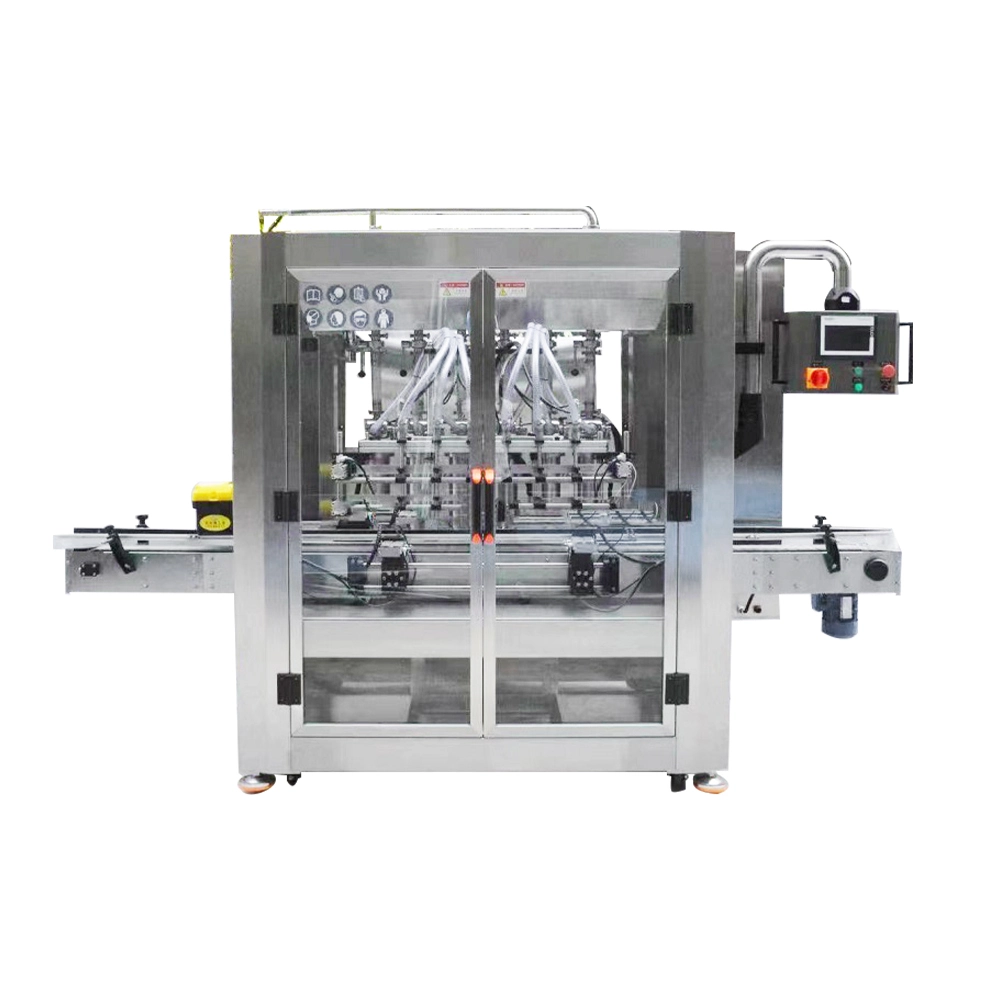

About us

Yuanyang is a top producer of industrial mixers and automated filling machines in China. Since 2008, we've been providing complete production line solutions, including mixing equipment, storage tanks, capping machines, labeling machines, sealing machines, inkjet printers, and water treatment equipment. Our automated filling machines are designed for high precision and efficiency, ensuring seamless production processes. We've got you covered with our full suite of services, including free tech training and one-stop installation support. Yuanyang has a bunch of CE certifications, and they're dead set on becoming the world's best industrial mixer and filling machine manufacturer. They're all about helping businesses get more done and improve their quality.

Conclusion

Filling machines are more than just mechanical devices; they are strategic assets that define the capacity and quality of your production. From the robust auger filler handling spices to the high-speed liquid line bottling water, these technologies enable businesses to scale and compete globally. By understanding the types of machines available and adhering to best practices in selection and maintenance, manufacturers can ensure their packaging lines are efficient, compliant, and ready for the future.For expert advice and high-quality filling machines, contact Yuanyang today and take your production to the next level.

FAQ

What is the primary function of a filling machine?

A filling machine's primary function is to accurately and efficiently dispense a specific amount of product (liquid, powder, granular, paste, or solid) into a container, ensuring consistency and reducing waste.

What are the main types of filling machines based on product type?

The main types include liquid filling machines (piston, gravity, pump), powder filling machines (auger, vibratory), solid/granular filling machines (volumetric cup, multi-head weigher), and paste/viscous product filling machines.

How do liquid filling machines differ from powder filling machines?

Liquid filling machines use fluid dynamics mechanisms like gravity, pistons, or flow meters to move product. Powder filling machines typically use augers (screws) or vibratory trays to move and measure dry particulates that flow differently than fluids.

What industries heavily rely on filling machines?

Industries such as food and beverage, pharmaceuticals, cosmetics, chemicals, and household products heavily rely on filling machines to maintain high production speeds and meet strict hygiene standards.

What factors should I consider when selecting a filling machine?

Key factors include product viscosity and characteristics, container type/size, desired production speed (BPM), required filling accuracy, budget, available floor space, and sanitation/regulatory requirements.

Can filling machines handle different container sizes?

Yes, modern filling machines are designed with flexibility in mind. They often feature adjustable guide rails and nozzles, or quick-change parts, allowing them to handle a wide range of container sizes and shapes on the same machine.

What are the benefits of automated filling machines?

Automated filling machines offer higher production speeds, superior filling accuracy, significantly reduced labor costs, consistent product quality, and improved hygiene by minimizing human contact.

How often should a filling machine be cleaned and maintained?

Cleaning frequency depends on the industry; food and pharma typically require daily cleaning. Maintenance should follow a preventive schedule (e.g., monthly checks of seals and motors) to avoid downtime and ensure longevity.

References

· IPackFilling - Top 10 Benefits of Using an Automatic Beverage Filling Machine

· Grand View Research - Filling Machines Market Size, Share & Trends Analysis Report (2022 - 2030)

· Ace Filling - What Are the Advantages of Using an Automated Water Bottling Machine?

How to Future-Proof Your Production Line: The Latest Innovations in Precision Filling Machinery (2026 Guide)

The Definitive Guide to Industrial Storage Tanks 2026: Why Food-Grade Stainless Steel is the Gold Standard

The Ultimate 2026 Guide to Liquid Filling Machines: Types, Technologies, and Strategic Selection

Ultimate Guide to Commercial Reverse Osmosis Systems 2026

Ultimate Storage Tank Guide for 2026: Selection & Innovations

Automatic Servo Motor Capping Machine

Can rotation speed of the bottle separator be controlled for this servo capper machine?

The speed to separate bottles can be controlled with frequency converter on the electric cabinet.

Desktop Labeling Machine

Is the supporting table in the pictures be sold together with automatic bottle labeling machine?

Yes, the regular quote does not include the supporting table which is optional, but we will provide if clients need, the table on wheels.

Homogenizer Mixing Tank with Circulation System

Can you add load cell system also for the liquid detergent making machine?

Yes, we add load cell upon requirements. Each mixer with 3 sets of load cell, and signal box, and display panel.

FAQs

What’s your payment term?

Generally, we take 30% of total amount as down payment, which should be wired by T/T. The 70% balance will be paid by T/T after you inspect your machines before shipment. We also accept letter of credit although it takes more expenses. But our bank should confirm your opening bank’s credit first.

Sachet Packaging Machine

Can I use this liquid packing machine to pack if my product is like paste which is quite thick and viscous?

Yes, heating function and mixing function can be added based on materials.

Leave a message

Have any questions or concerns about our products? Please leave us a message here, and our team will get back to you promptly.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery