Automatic Bottle Capping Machines

# Automatic Bottle Capping Machines: Precision & Efficiency for Your Production Line

Why Choose an Automatic Bottle Capping Machine?

Automate your packaging process with YUANYANG’s automatic bottle capping machines, designed for high-speed, error-free sealing. These machines eliminate manual labor, reduce contamination risks, and ensure consistent torque control for leak-proof closures—ideal for pharmaceuticals, cosmetics, food, and chemical industries.

Key Features of YUANYANG’s Capping Solutions

- High-Speed Performance: Cap up to 200 bottles per minute with precision.

- Versatile Compatibility: Works with screw caps, snap caps, and pump dispensers.

- Durable Construction: Stainless steel components for long-term reliability.

- Easy Integration: Seamlessly connects with filling and labeling machines.

Industries We Serve

Our automatic bottle capping machines cater to:

- Pharmaceuticals: Ensures tamper-evident, sterile sealing.

- Cosmetics: Maintains product integrity with airtight closures.

- Food & Beverage: Complies with hygiene and safety standards.

Turnkey Solutions & CE-Certified Quality

YUANYANG provides complete production lines, including mixing, filling, capping, and labeling. Our machines are CE-certified, meeting EU safety regulations, and come with free technical training and installation support.

Upgrade your packaging efficiency with YUANYANG—China’s trusted industrial equipment manufacturer since 2008. Contact us today for a customized solution!

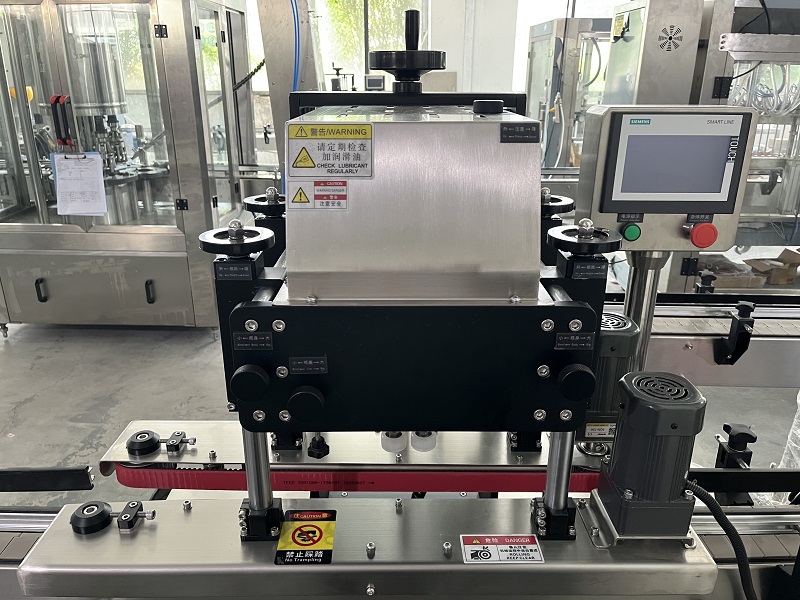

automatic bottle capping machine Display

I want to connect the melting tank with my filling machine, can you help to customize the height to 70cm and provide adapters?

Yes, we would like to help give solutions according to actual situation. Yuany is a professional solution provider. Purchasing machines from Yuany not only saves cost but also saves energy and time.

Do you have PLC control panel for the soap mixing tank?

Yes, the control panel can be button control or with PLC touch screen. The standard is with button control, clients choose based on budget. we will customize upon requirements.

What types bottles are suitable for this automatic labeling machine?

The automatic labeling machine for bottles is suitable for round bottles, jars, cans, bucket. It is a round bottle labeling machine.

What’s the brand of motor for this vacuum emulsifying mixer?

We have different brand of motor for clients to choose. The standard motor brand is Beide, optional choice is Siemens and ABB.

Is the plastic bottle capping machine electric drive or pneumatic drive?

This bottle cap closing machine is with both electric drive and pneumatic drive. It requires an air compressor.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery