High Shear Mixer vs. Homogenizer: Choosing the Right Industrial Mixer for Your Process

High Shear Mixer vs. Homogenizer: Choosing the Right Industrial Mixer for Your Process

As a trailblazer in industrial mixing solutions since 2008, YUANYANG understands that the heart of any successful production lies in precise and efficient mixing. From pharmaceuticals to cosmetics, food to chemicals, achieving optimal product consistency, stability, and texture is paramount. Two fundamental pieces of equipment often come into discussion: the high shear mixer and the homogenizer. While both aim to create uniform mixtures, their mechanisms, applications, and results differ significantly. Understanding these distinctions is key to selecting the ideal equipment for your specific needs.

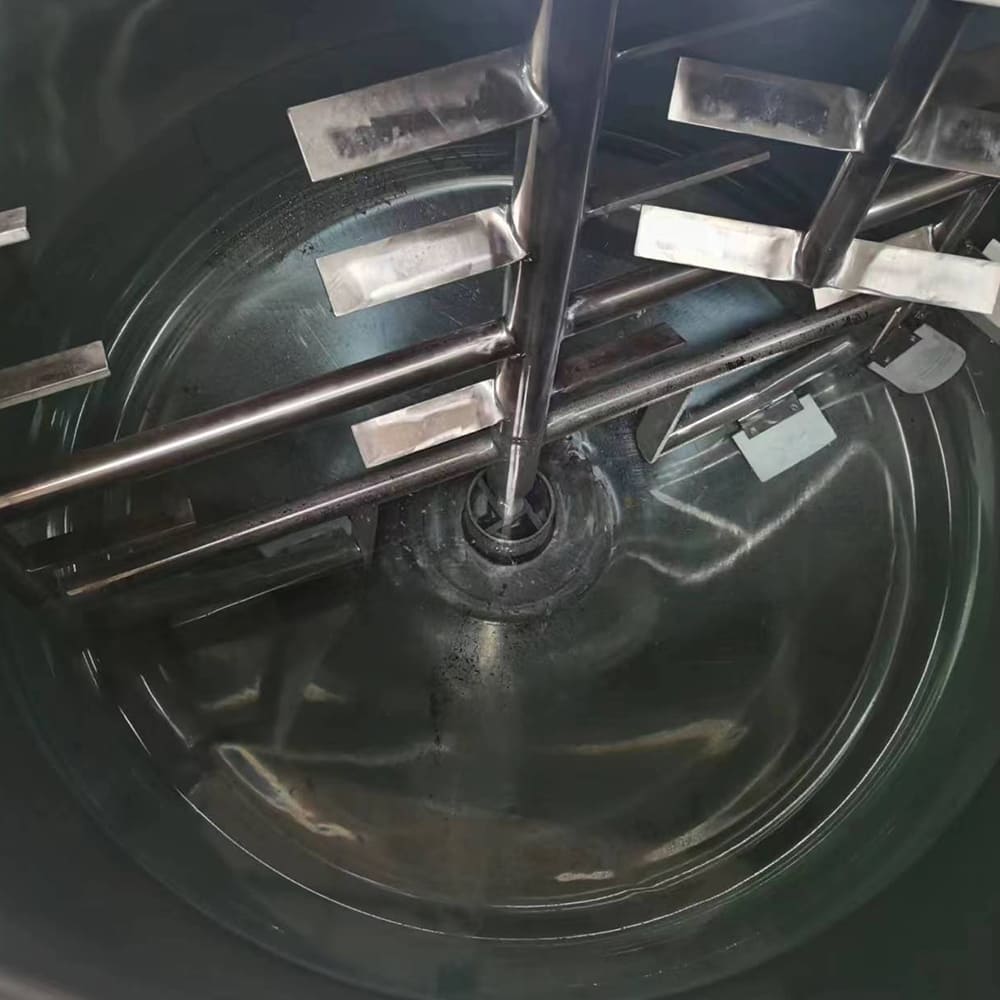

Unlocking Efficiency with High Shear Mixers

YUANYANG's high shear mixers are engineered to rapidly disperse, emulsify, and dissolve solids or liquids into another continuous phase. They operate by employing a rotor-stator mechanism that generates intense mechanical and hydraulic shear forces. This powerful action quickly reduces particle size, breaks down agglomerates, and creates stable emulsions and suspensions. Our high shear mixers are incredibly versatile, excelling in applications requiring quick mixing, fine dispersion, or the creation of high-viscosity products. They are often the go-to choice for manufacturing creams, lotions, sauces, paints, and many chemical formulations where rapid ingredient incorporation and particle size reduction are critical.

Achieving Finer Particle Sizes with Homogenizers

For processes demanding even finer particle size reduction and superior long-term stability, YUANYANG's vacuum homogenizers are the solution. Homogenizers typically operate by forcing a mixture at high pressure through a very narrow gap or valve. This process, involving intense shear, turbulence, and cavitation, reduces fat globules or particles to sub-micron sizes, preventing separation and settling over time. Ideal for ultra-fine emulsions and suspensions, homogenizers are indispensable in industries producing milk, juices, pharmaceutical emulsions, and fine chemical dispersions where maximum stability and uniform distribution are non-negotiable.

High Shear Mixer vs. Homogenizer: Making the Informed Choice

The primary difference between a high shear mixer and a homogenizer lies in the intensity of shear and the resulting particle size reduction.

- High Shear Mixers offer excellent dispersion and emulsification with significant particle size reduction, suitable for a broad range of products, especially those requiring rapid processing and moderate fineness. They are typically more cost-effective for initial investment and maintenance.

- Homogenizers, on the other hand, provide much higher shear forces, achieving significantly smaller, often sub-micron, particle sizes. This results in superior stability and shelf-life, making them essential for high-end emulsions and suspensions where the utmost uniformity is paramount.

When deciding, consider your product's desired particle size, stability requirements, viscosity, throughput, and budget. Our experts at YUANYANG can guide you through this critical decision, ensuring you invest in the most effective solution for your production goals.

Partner with YUANYANG for high quality Mixing Solutions

As one of China's leading manufacturers of industrial mixers and agitators, YUANYANG is committed to delivering excellence. Our vacuum homogenizers and high shear mixers are built to the highest standards, backed by multiple CE certifications, affirming our dedication to safety and health. Beyond world-class equipment, we provide comprehensive production line solutions, free technical training, and one-stop installation support, offering a full suite of turnkey services. Our vision is to be the best industrial mixer and agitator manufacturer globally, and we achieve this by partnering with you to optimize your processes.

Explore our range of industrial mixers today and let YUANYANG elevate your production capabilities. Visit (https://www.yuanymachinery.com/) or contact us for a personalized consultation.

high shear mixer vs homogenizer Display

What’s the maximum temperature the melting pot can get?

The tank is with electric heater, add water to conduct heat through jacket layer. Therefore the maximum temperature is 100°C.

Are the equipment compliant with industry regulations?

Yes, Yuanyang’s equipment meets GMP, FDA, and other relevant industry regulations, ensuring high-quality and safety standards.

Do you support international shipping and installation?

Yes, we provide global delivery services and offer international installation and commissioning services to ensure you can smoothly use the equipment for production.

What type of powders is the plastic bag packing machine suitable for?

The packing machinery for powders include various types such tea powder, walnut powder, mini granules, coffee powder, corn powder, rice powder, milk powder, etc.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery