Automatic Bottle Labeling Machine

Automatic Bottle Labeling Machine Solutions from YUANYANG

Efficient and Precise Labeling for Every Industry

YUANYANG’s automatic bottle labeling machines streamline your packaging process, delivering fast, accurate, and consistent labeling for bottles of all shapes and sizes. Whether you need labeling for cosmetics, pharmaceuticals, food, or chemicals, our advanced equipment ensures professional results every time.

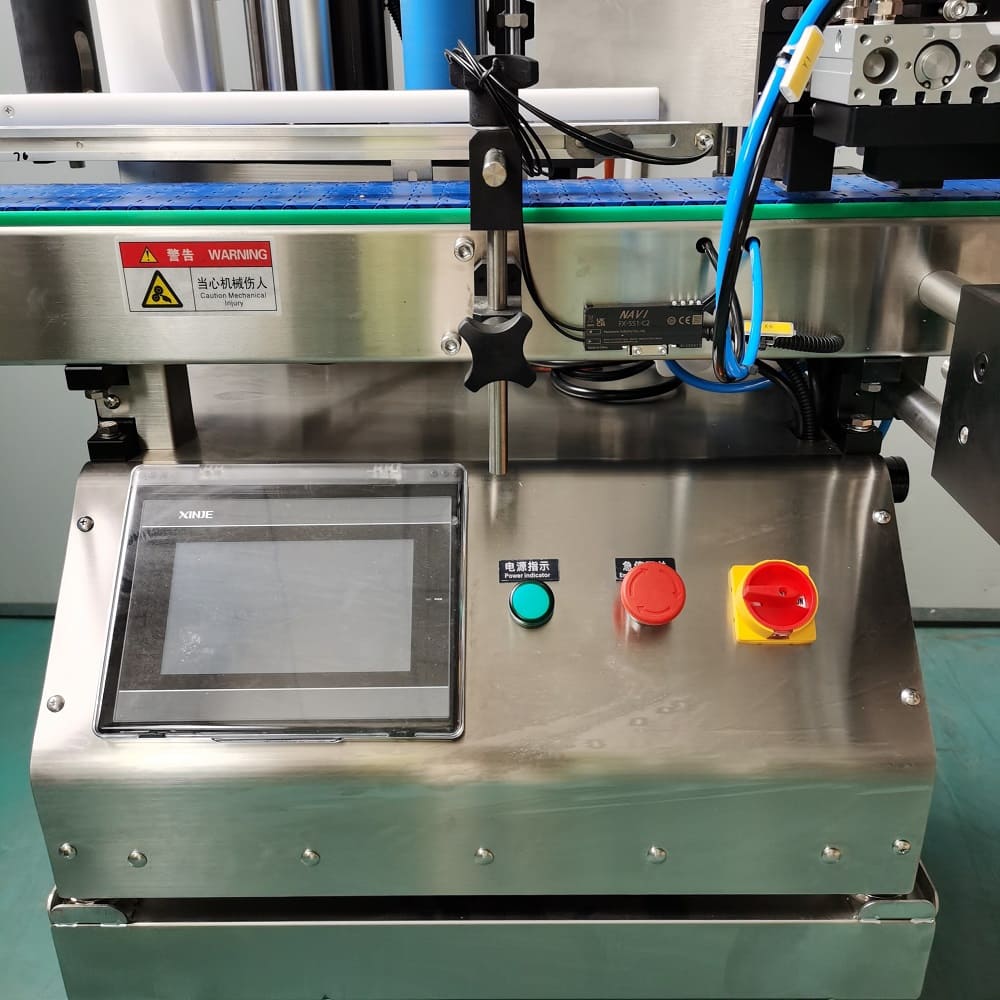

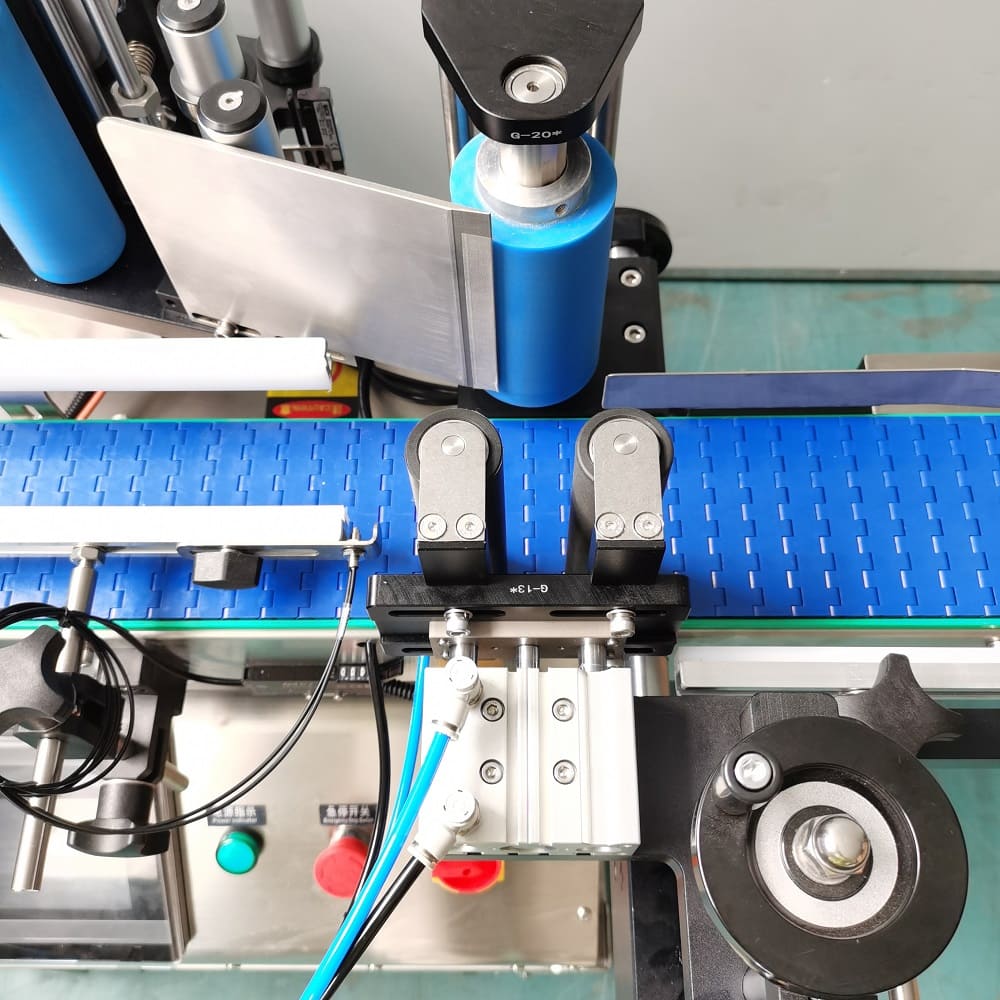

Cutting-Edge Technology with User-Friendly Operation

Built with the latest automation features, YUANYANG’s automatic bottle labeling machines are engineered to maximize productivity while minimizing human error. Intuitive controls and smart sensors guarantee easy setup and reliable performance, reducing downtime and maintenance costs.

Integrated Production Line Support

As a leading China-based machinery manufacturer, YUANYANG offers more than just labeling solutions. We provide complete production line equipment, including vacuum mixers, filling, capping, sealing, and coding machines. Our one-stop service ensures seamless integration, from mixing and filling to labeling and packaging.

Turnkey Service and Technical Support

Choosing YUANYANG means accessing free technical training and expert guidance for machine installation and operation. Our experienced engineers help you configure your automatic bottle labeling machines for maximum efficiency, while our after-sales team guarantees ongoing support.

Quality Assurance and CE Certification

All of YUANYANG’s automatic bottle labeling machines are CE certified, demonstrating compliance with strict European safety and health standards. Trust in our reliable machines, backed by over 15 years of industry experience, to grow your business with confidence.

Optimize your production with YUANYANG’s automatic bottle labeling machines—experience precision, efficiency, and world-class support.

automatic bottle labeling machine Display

The capping wheel is a little high for the small bottles, do you have solutions?

Yes, we have designed cylinder type for mini bottles.

Do you supply steam generator and provide steam and cooling pipes together for the mixing tank with homogenizer machine?

If the mixing tank is with steam heating, we will help to supply steam generator and provide steam and cooling pipes. But this is an optional choice. Client can prepare by steam generator by himself. The steam pipe is usually quoted separately.

What type of bottles can it be suitable for ?

The screw capping machine is mainly used for plastic bottles. The cap can be pump head, sprayer, triggers, and various other screw caps.

Which do you recommend, steam heating or electric heating?

To save cost, electric heating is recommended, especially for small capacity soap mixing tank; Steam heating requires a steam generator, if client has steam generator, steam heating is recommended.

How can I ensure my production process is free from contamination?

Our equipment uses materials that meet the strict standards of the pharmaceutical industry and is designed for easy cleaning and maintenance. All our equipment is carefully designed to minimize the risk of cross-contamination.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery