Chemical Tank Mixing Solutions

Innovative Chemical Tank Mixing Technology by YUANYANG

Precision Mixing for Industrial Applications

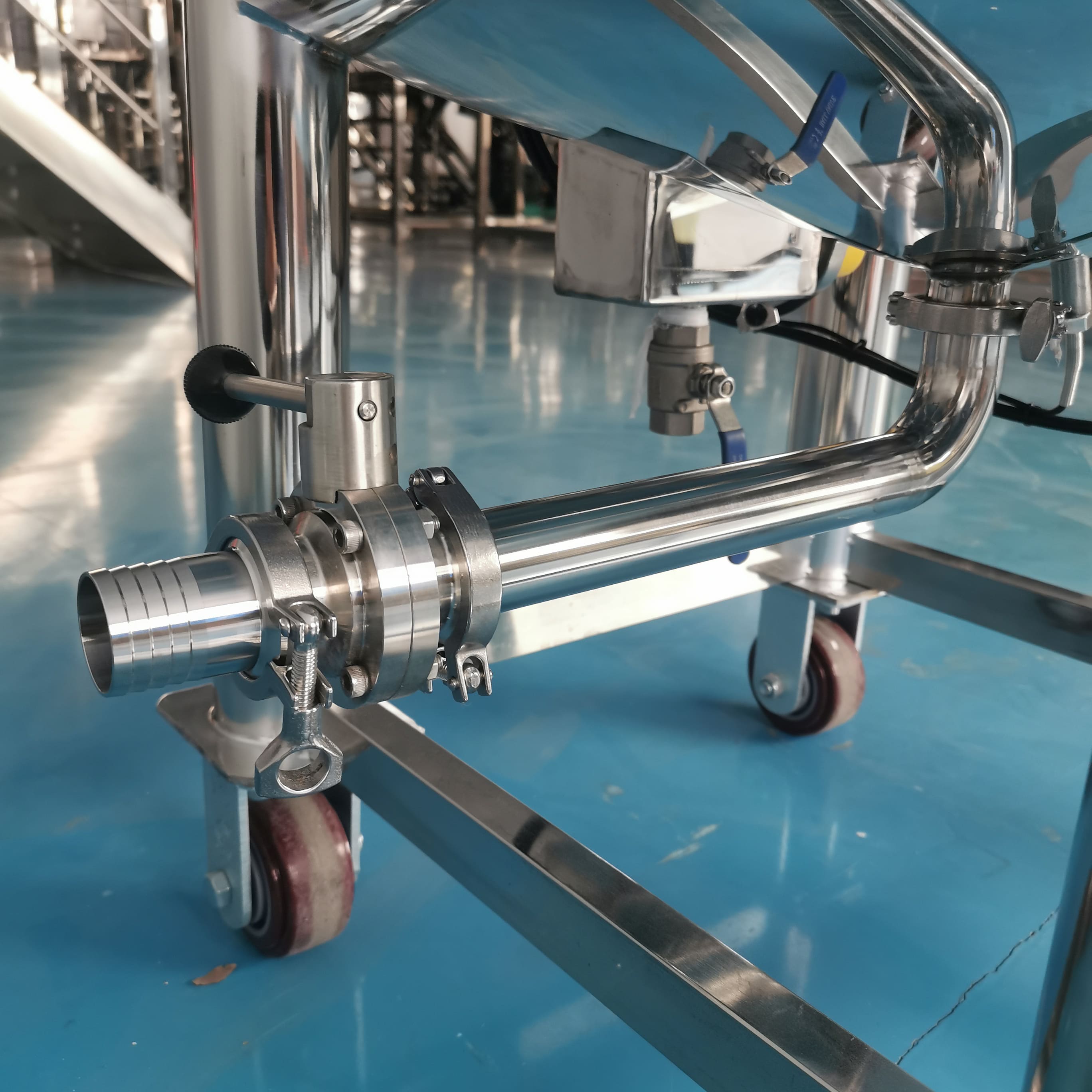

YUANYANG’s chemical tank mixing technology ensures uniform blending, reducing processing time while maintaining product integrity. Our high-shear mixers and vacuum homogenizers deliver consistent viscosity, stability, and dispersion—ideal for chemicals, coatings, and pharmaceuticals.

Advanced Equipment for Optimal Performance

From vacuum emulsifying mixers to high-shear homogenizers, YUANYANG provides cutting-edge solutions. Our CE-certified machines guarantee safety, efficiency, and compliance with European standards, ensuring seamless integration into your production line.

Customized Turnkey Solutions

Beyond mixers, YUANYANG offers complete production lines, including storage tanks, filling machines, and water treatment systems. Our one-stop support covers installation, training, and maintenance, minimizing downtime and maximizing productivity.

Why Choose YUANYANG?

- CE-certified for safety & compliance

- 15+ years of industrial mixing expertise

- Custom-engineered solutions for diverse industries

- Free technical training & installation support

Upgrade your chemical processing with YUANYANG’s reliable mixing technology—where innovation meets efficiency. Contact us today for a tailored solution!

This content is , user-friendly, and professionally structured to enhance search rankings while maintaining readability. Let me know if you need refinements!

chemical tank mixing technology Display

Can the equipment handle organic or sensitive formulations?

Yes. Our equipment is designed to handle various special formulations, including organic, additive-free, and sensitive formulations, ensuring no contamination or degradation during processing.

How can I ensure my production process is free from contamination?

Our equipment uses materials that meet the strict standards of the pharmaceutical industry and is designed for easy cleaning and maintenance. All our equipment is carefully designed to minimize the risk of cross-contamination.

What’s the available mesh for the filter screen?

The mesh varies from 2-500 mesh. Customer service will recommend clients the most suitable mesh according to materials and requirements.

How long is the suction hose?

This hose is about 1.3 meters long. Can be longer upon requirements.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery