Automatic Can Labeling Machine

Automatic Can Labeling Machine: Precision and Efficiency for Your Production Line

Optimize Labeling Process with Automatic Can Labeling Machines

Increase your production line’s efficiency with a YUANYANG automatic can labeling machine. Our advanced technology delivers precise labeling at high speed, reducing manual work and increasing productivity. Designed for different can sizes and materials, these machines ensure consistent application and professional results for every batch.

Key Features of YUANYANG Automatic Can Labeling Machines

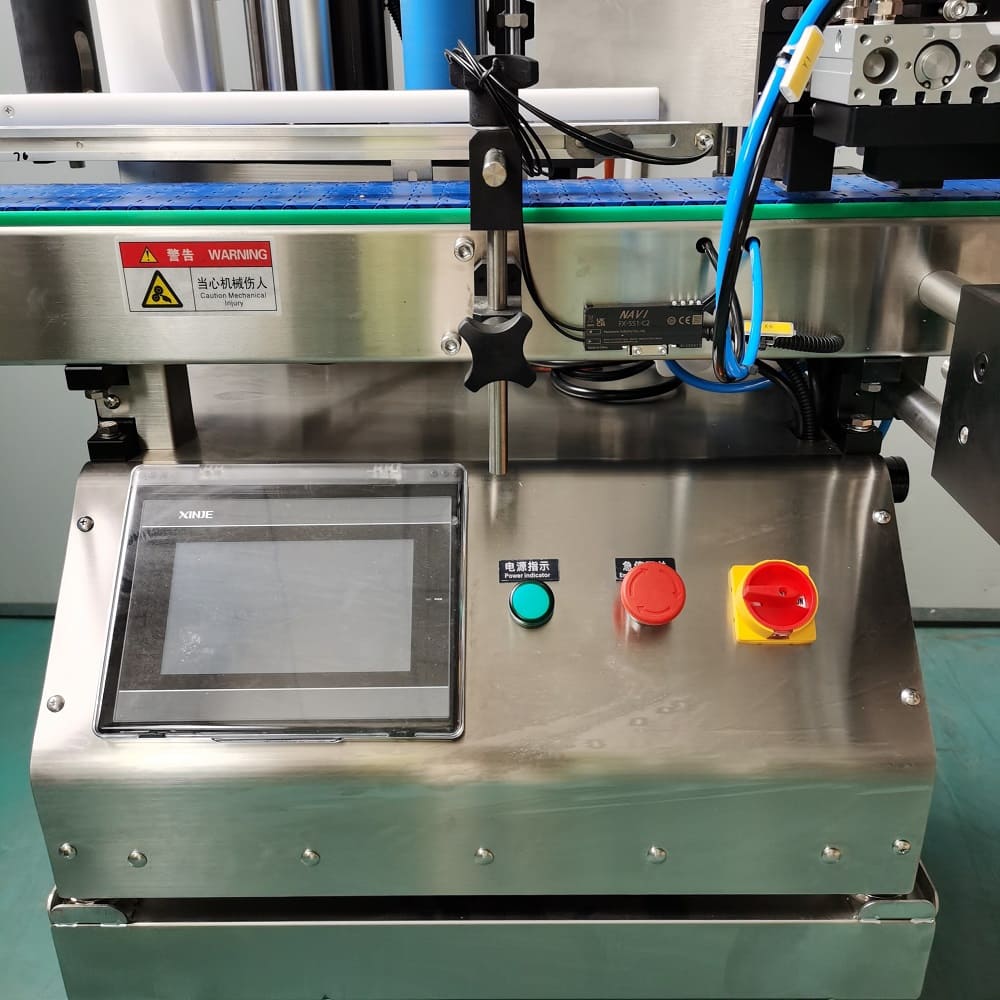

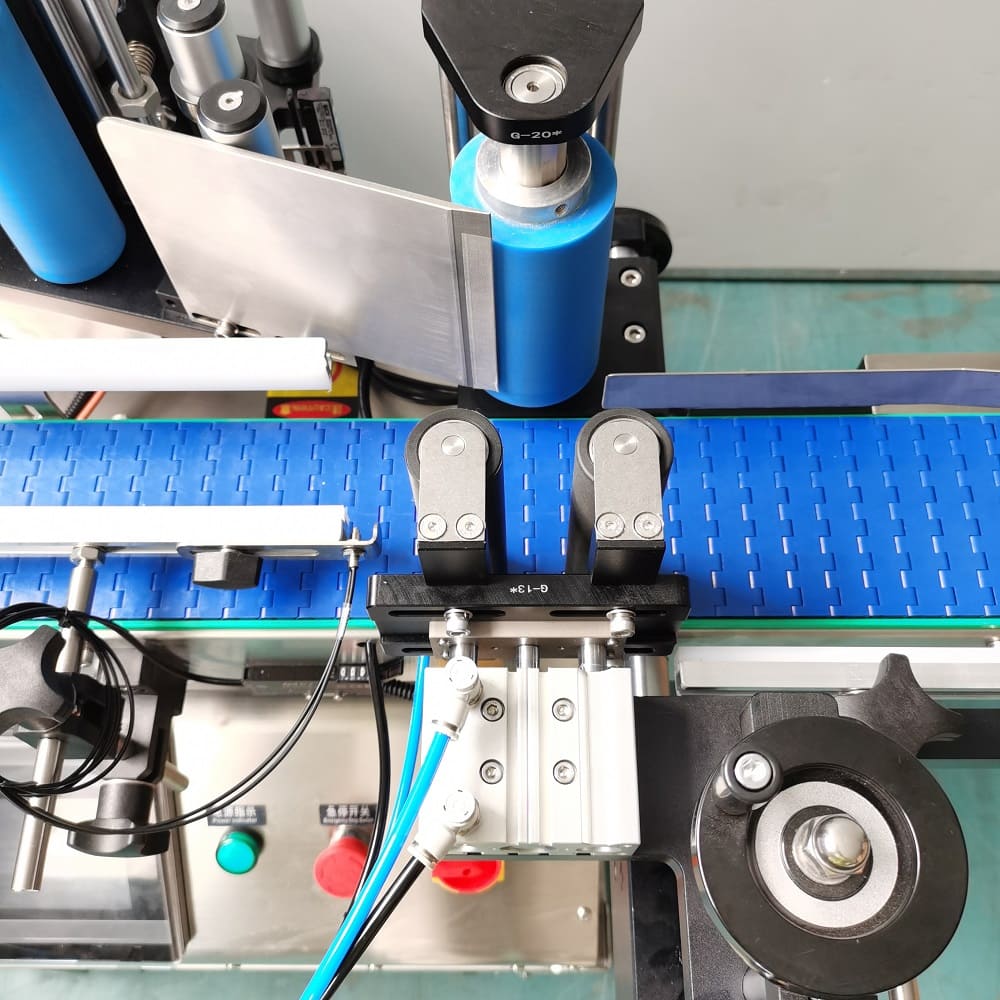

YUANYANG’s automatic can labeling machines are equipped with intelligent sensors, user-friendly touchscreens, and durable components for long-term reliability. Fast label changeovers and minimal downtime are made possible by our highly adaptable designs. Whether labeling metal, plastic, or composite cans, our machines maintain tight tolerances for accurate placement every time.

Seamless Turnkey Solutions and Expert Support

As a leader in industrial mixing and packaging solutions, YUANYANG delivers more than just machines. We offer complete production lines, including mixers, storage tanks, filling, capping, sealing, and coding machines. Our turnkey services include installation, free technical training, and ongoing support to maximize your investment and minimize setup time.

Why Choose YUANYANG for Automatic Can Labeling?

Since 2008, YUANYANG has earned a reputation for quality, innovation, and customer service. Our automatic can labeling machines are CE certified, ensuring compliance with European safety and health standards. Trust our expert team to help you select, install, and operate the ideal solution for your labeling needs—making your production faster, smoother, and more reliable.

automatic can labeling machine Display

Can you customize the discharge port height for the powder sieve shaker machine?

Yes, if client has discharge height requirement, just tell us to customize.

Can you provide custom service?

Definitely we offer customization service. For example, the thickness of layers, the brand of motor, the mixing types, the power of motor, power supply.

Can I visit your factory?

Yes,welcome to visiting our factory.Our factory is located in Guangzhou, China. You could visit us by taxi or by metro. Our company can pick you up. Please contact our customer service for appointment in advance.

What’s the hopper capacity of the feeding machine for powder?

The standard feeder hopper capacity is 150L, can be customized.

How is installation and commissioning done?

We provide detailed written manuals and remote video guidance, or on-site installation and commissioning services to ensure the equipment is quickly operational.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery