Double Side Labeling Machine Manufacturer–YUANYANG Labeling Solutions

Double Side Labeling Machine Solutions for Every Business

Precision and Efficiency in Product Labeling

YUANYANG’s double side labeling machines deliver fast, accurate, and consistent labeling for bottles, jars, and containers in all shapes. Designed for both flat and round bottles, our machines can place labels smoothly on both sides at amazing speeds, improving your production line's efficiency.

Customizable for All Your Production Needs

Whether you operate in the food, beverage, cosmetic, or pharmaceutical industry, YUANYANG provides double side labeling machines that fit your specific requirements. Flexible adjustment options and compatibility with different label sizes allow you to handle diverse packaging types without hassle.

Built for Durability and Reliability

Manufactured to the highest international standards, every YUANYANG double side labeling machine is CE certified for a trusted guarantee of safety and performance. Our robust, low-maintenance design ensures long-term reliability even under continuous operation.

One-Stop Service and Technical Support

As part of YUANYANG’s complete production line equipment suite, our labeling machines integrate seamlessly with mixers, filling, capping, and sealing machines. We offer free technical training and installation services to ensure your entire labeling setup runs smoothly from day one.

Why Choose YUANYANG Double Side Labeling Machines?

- Over 15 years of experience in industrial machinery

- Complete turnkey solutions

- Backed by professional factory support and after-sales service

Upgrade your labeling process with YUANYANG’s double side labeling machine. Contact us today for your custom solution!

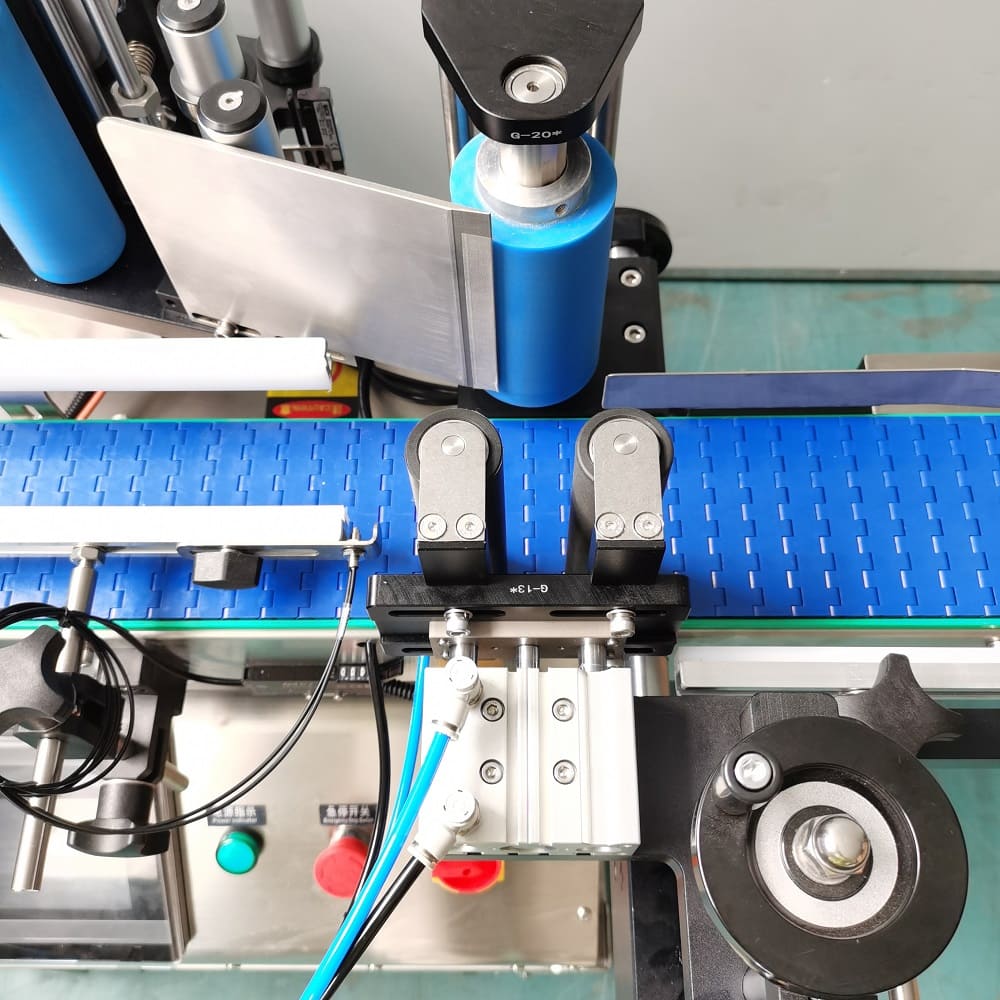

double side labeling machine Display

What minimum caps size can the desktop capping machine be suit for?

The minimum cap size is 20mm, it is recommend to send caps to test if it is around 20mm.

What’s the date printing, steel printing or coding?

There are standard steel date printing on the automatic packaging machine, if clients needs coding type, just tell us to add an extra coding device.

Can you add a lid for the storage tank?

Yes, the lid can be added and customized. For example, with a central hole for overhead mixer, with a material hopper for adding powder or liquids.

Can the hose be used to fill high temperature liquids?

The hose can bear 70 degree temperature.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery