Elevate Your Production: Understanding Industrial Mixers & Homogenizers with YUANYANG

Elevate Your Production: Understanding Industrial Mixers & Homogenizers with YUANYANG

In countless industries, from cosmetics and pharmaceuticals to food and chemicals, achieving perfect product consistency and stability is paramount. At YUANYANG, a leading manufacturer of industrial mixers and agitators since 2008, we empower businesses worldwide with cutting-edge mixing solutions. Understanding the nuanced differences between a traditional mixer and a high-performance homogenizer is crucial for optimizing your production line.

Homogenizer vs Mixer: The Essential Distinction

While often used interchangeably, industrial mixers and homogenizers serve distinct purposes, each vital for specific processing goals. An industrial mixer, or industrial agitator, is primarily designed for blending, stirring, and gentle agitation. Its role is to combine various ingredients, maintain suspension, or facilitate chemical reactions, creating a uniform mixture without drastically altering particle size. Think of it for simple blending of liquids or dissolving solids, where the primary need is uniform distribution.

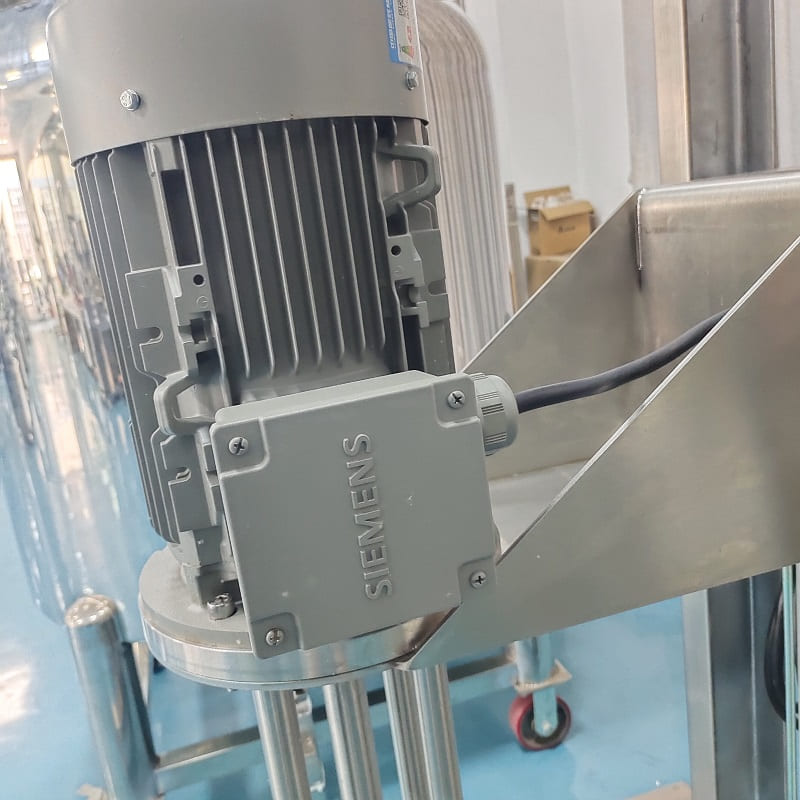

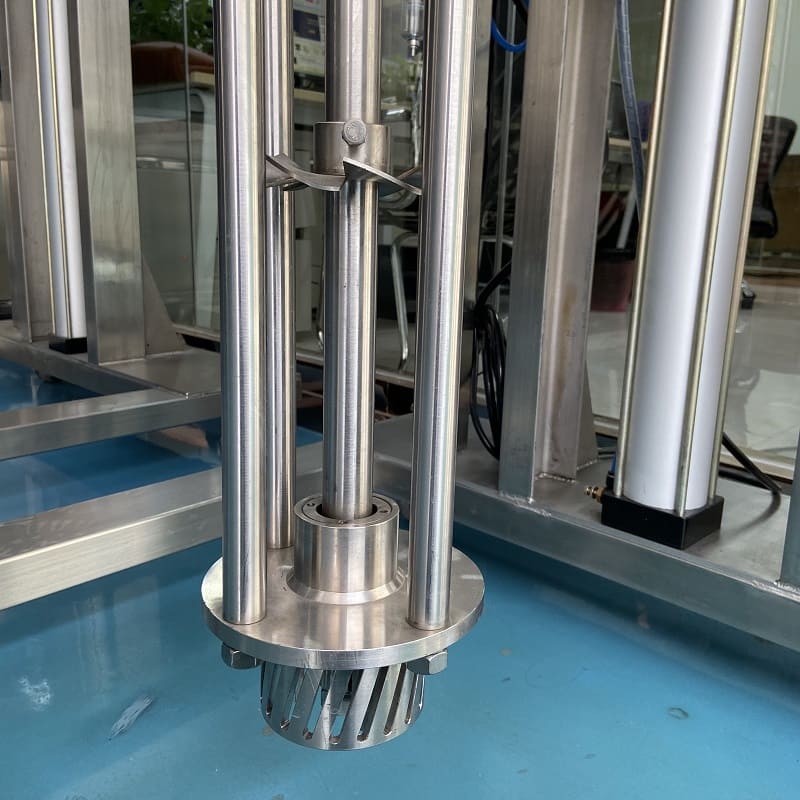

A homogenizer, particularly a high shear homogenizer like those offered by YUANYANG, goes a significant step further. It employs intense mechanical forces – shear, impact, and cavitation – to reduce particle size, disperse immiscible liquids, and create stable emulsions or suspensions. This advanced process results in a finely divided, uniform, and stable product, preventing separation over time. Our vacuum homogenizers and vacuum emulsifying mixers are engineered for applications demanding superior texture, consistency, and extended shelf-life, such as fine creams, lotions, or stable food emulsions.

YUANYANG's Comprehensive Range of Mixing Solutions

At YUANYANG, we pride ourselves on providing a diverse portfolio of industrial mixing equipment tailored to your exact needs. Our main products include:

- Vacuum Homogenizers: Ideal for products requiring high shear mixing under vacuum conditions, preventing air bubbles and ensuring product purity and stability.

- Vacuum Emulsifying Mixers: Perfect for creating stable emulsions in industries like cosmetics, pharmaceuticals, and food, ensuring smooth and consistent products with enhanced shelf-life.

- High Shear Mixers: Designed for rapid and efficient mixing, dispersion, and emulsification, significantly reducing processing times for various liquid and semi-liquid applications.

- Other Vacuum Mixers: Offering versatility for various applications where controlled environments and precise mixing are essential.

Beyond individual units, YUANYANG specializes in delivering complete production line equipment, from storage tanks to filling and labeling machines, providing a seamless, integrated solution for your facility.

Why Partner with YUANYANG?

Choosing YUANYANG means opting for unparalleled expertise and dedicated support. Since 2008, our commitment has been to provide not just equipment, but a full set of turnkey services. We offer free technical training and one-stop installation support, ensuring a smooth setup and operation. Our products, including our robust industrial mixers and agitators, hold multiple CE certifications, signifying adherence to stringent EU safety and health standards. While not a quality mark, it underscores our dedication to manufacturing reliable and compliant machinery for global markets. YUANYANG’s vision is clear: to become the best industrial mixer and agitator manufacturer in the world, achieved by consistently delivering innovative, high-performance solutions and exceptional customer service.

Ready to achieve superior product quality and operational efficiency? Explore our range of industrial mixers and homogenizers at www.yuanymachinery.com and let YUANYANG elevate your production.

homogenizer vs mixer Display

Is there a bottle gripper to keep thin bottles stable?

Yes, the auto servo capping machine is equipped with pneumatic clamping device for bottle stability.

Is there any temperature control? Can I set a targeted temperature?

Yes,there is temperature control display and controller on the control panel. Before heating operation, just set a temperature that you want, it can keep constant temperature;

Can the pipe of the powder feeding machine be customized

Yes, the pipe size can be customized according to materials.

Can the capping head lift up and down?

Yes, the servo capping machines have servo motors for adjustment of capping height, can achieve lift up and down directly by touch screen control.

How do I choose the right machine for my production needs?

Our experts will analyze your production goals, product types, batch sizes, and packaging requirements to recommend the most suitable equipment, ensuring an efficient and cost-effective production process.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery