Automatic Capping Machine | YUANYANG

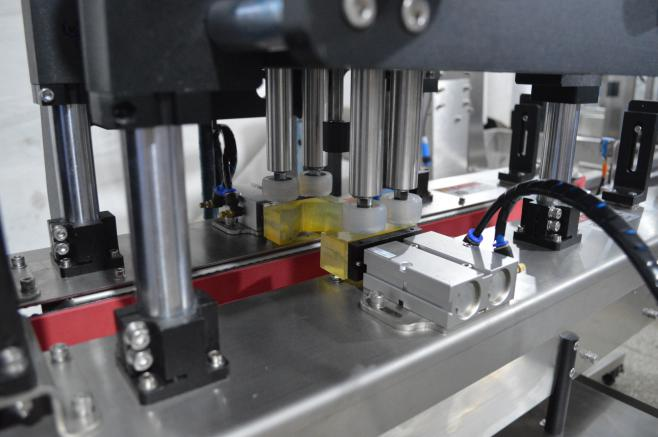

Automatic Plastic Caps Capping Machine

High-Speed & Efficient Capping

YUANYANG's Automatic Plastic Caps Capping Machine delivers unparalleled speed and efficiency in your capping process. Our machines are designed for seamless integration into existing production lines, minimizing downtime and maximizing output. The integrated vibrating cap feeder ensures a consistent and reliable supply of caps, preventing bottlenecks and maintaining a smooth workflow.

Reliable & Durable Construction

Built to last, our capping machines utilize robust materials and advanced engineering principles. This ensures long-term reliability and minimizes maintenance needs, contributing to reduced operational costs over the machine's lifespan. YUANYANG's commitment to quality is evident in every detail of our manufacturing process.

Versatile & Customizable Solutions

Our Automatic Plastic Caps Capping Machines are adaptable to a wide range of bottle sizes and cap types. We offer customization options to meet specific production requirements, ensuring optimal performance in your unique application. Contact us to discuss your specific needs and explore tailored solutions.

Complete Turnkey Solutions from YUANYANG

YUANYANG provides more than just capping machines. As a leading provider of complete production line solutions since 2008, we offer a wide array of equipment, including mixers, fillers, labelers, and more. Benefit from our expertise and streamlined one-stop service, including free technical training and installation support.

CE Certified Quality & Safety

Our commitment to safety and compliance is demonstrated by our CE certification. This ensures that our machines meet stringent European Union safety standards. Rest assured that your investment in a YUANYANG Automatic Plastic Caps Capping Machine is an investment in quality and peace of mind.

Automatic Plastic Caps Capping Machine with Vibrating Cap Feeder for sale Display

Is the speed adjustable with VFD?

The chemical mixer tank is often with frequency converter. But some clients may just need a fixed speed. So we customize upon requirements.

The products is too viscous, is the chemical storage tank easy for discharge?

We recommend pressurized storage tank type for easy discharge.

Can the equipment handle organic or sensitive formulations?

Yes. Our equipment is designed to handle various special formulations, including organic, additive-free, and sensitive formulations, ensuring no contamination or degradation during processing.

What’s the maximum weight that the automatic powder packing machine pack?

The maximum filling weight is 1000g. For packing weight over 1000g, the semi automatic powder filler is recommended.

How is installation and commissioning done?

We provide detailed written manuals and remote video guidance, or on-site installation and commissioning services to ensure the equipment is quickly operational.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery