Sticker Labeling Machine Supplier

Sticker Labeling Machines – Efficient Labeling for Modern Production Lines

Enhance Productivity with Advanced Sticker Labeling Machines

Upgrade your production line with YUANYANG’s high-performance sticker labeling machines. Designed for accuracy and speed, our labeling solutions automate the sticker application process, ensuring each product is consistently branded and ready for market. Whether you operate in food, cosmetics, pharmaceuticals, or daily chemicals, our machines fit seamlessly into your existing workflow.

Reliable Technology for Consistent Labeling Results

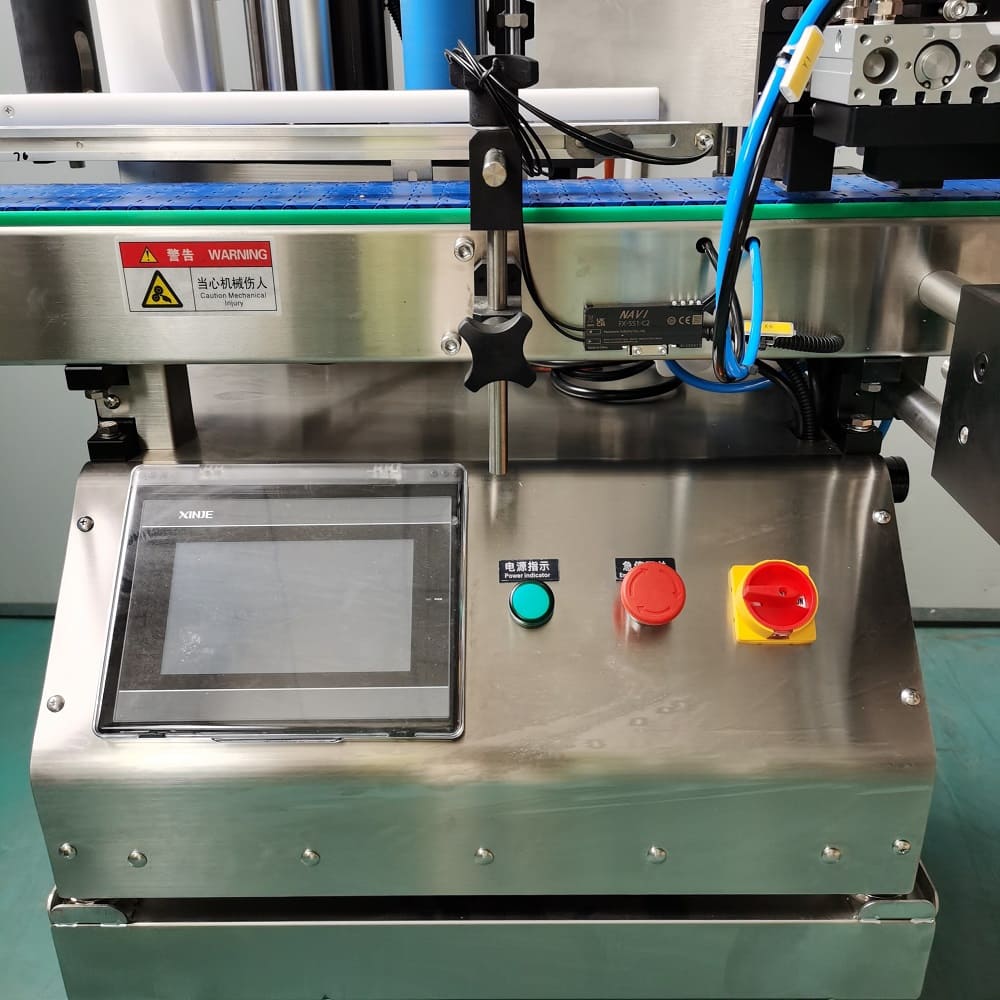

At YUANYANG, we combine robust engineering with user-friendly controls. Our sticker labeling machines feature advanced sensors and adjustable components to handle various product sizes, bottle shapes, and labeling materials. This flexibility guarantees a professional finish on every item, reducing labeling errors and minimizing waste.

Easy Integration and Full Technical Support

Integrating our sticker labeling machines into your manufacturing process is hassle-free. We offer free technical training and complete installation support, making it simple for you to achieve a turnkey labeling solution. Count on YUANYANG’s experience since 2008 and our CE-certified equipment for peace of mind and regulatory compliance.

Why Choose YUANYANG Sticker Labeling Machines?

- Precision and efficiency for any packaging scale

- Robust, easy-to-maintain industrial design

- CE-certified for safe, reliable operation

- Comprehensive after-sales support and training

- One-stop solution including mixers, fillers, and other packing equipment

Invest in YUANYANG’s sticker labeling machines and elevate your productivity today. Request a quote or consultation to discover the perfect solution for your business.

sticker labeling machine Display

Do you have other types of labeling machine?

Yes, there are several types of labeling machine, including semi-automatic labeling machine, automatic labeling machine, round bottle labeling machine, flat labeling machine, double sides labeling machine, square bottle labeling machine.

Can the equipment handle organic or sensitive formulations?

Yes. Our equipment is designed to handle various special formulations, including organic, additive-free, and sensitive formulations, ensuring no contamination or degradation during processing.

How do you handle unexpected downtime or failures during production?

Our equipment is equipped with an intelligent fault detection system that monitors the operational status in real-time, automatically alerts and stops operation when issues arise, ensuring safety. Additionally, our technical support team offers 24/7 remote and on-site services to quickly address equipment failures.

What’s the maximum and minimum height can the automatic sealing machine lift up and go down?

The maximum height for the sealing head to the floor is 75-120cm.

What type of powders is the plastic bag packing machine suitable for?

The packing machinery for powders include various types such tea powder, walnut powder, mini granules, coffee powder, corn powder, rice powder, milk powder, etc.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery