Automatic Round Bottle Labeling Machines | YUANYANG

# Automatic Round Bottle Labeling Machines for Sale

High-Speed & Efficient Labeling

YUANYANG's automatic round bottle labeling machines are designed for speed and precision. Our machines handle various bottle sizes and shapes, significantly increasing your labeling output while minimizing manual labor and associated errors. Improve your production line efficiency and reduce operational costs.

Reliable & Durable Construction

Built with robust materials and advanced engineering, our labeling machines guarantee longevity and consistent performance. Years of experience in manufacturing industrial equipment ensures top-tier quality and reliable operation. Reduce downtime and maintenance expenses with a YUANYANG machine.

Versatile Application & Customization

Our automatic labeling machines are suitable for a wide range of industries and products. From pharmaceuticals and cosmetics to food and beverages, our customizable solutions adapt to your specific needs. Contact us to discuss your unique requirements and explore tailored solutions.

Complete Turnkey Solutions & Support

YUANYANG provides comprehensive turnkey solutions, including installation, training, and ongoing support. Benefit from our expertise and receive free technical training to ensure seamless integration into your existing production line. Our team is committed to your success.

CE Certified Quality & Assurance

Our commitment to quality is reflected in our CE certification. This demonstrates our adherence to stringent safety and health standards, ensuring a secure and reliable operation. Choose a YUANYANG labeling machine for peace of mind and compliance.

About YUANYANG

Since 2008, YUANYANG has been a leading manufacturer of industrial mixing and blending equipment, offering complete production line solutions, including labeling, filling, and sealing machinery. We are committed to providing high-quality, reliable machinery and comprehensive support to our clients globally.

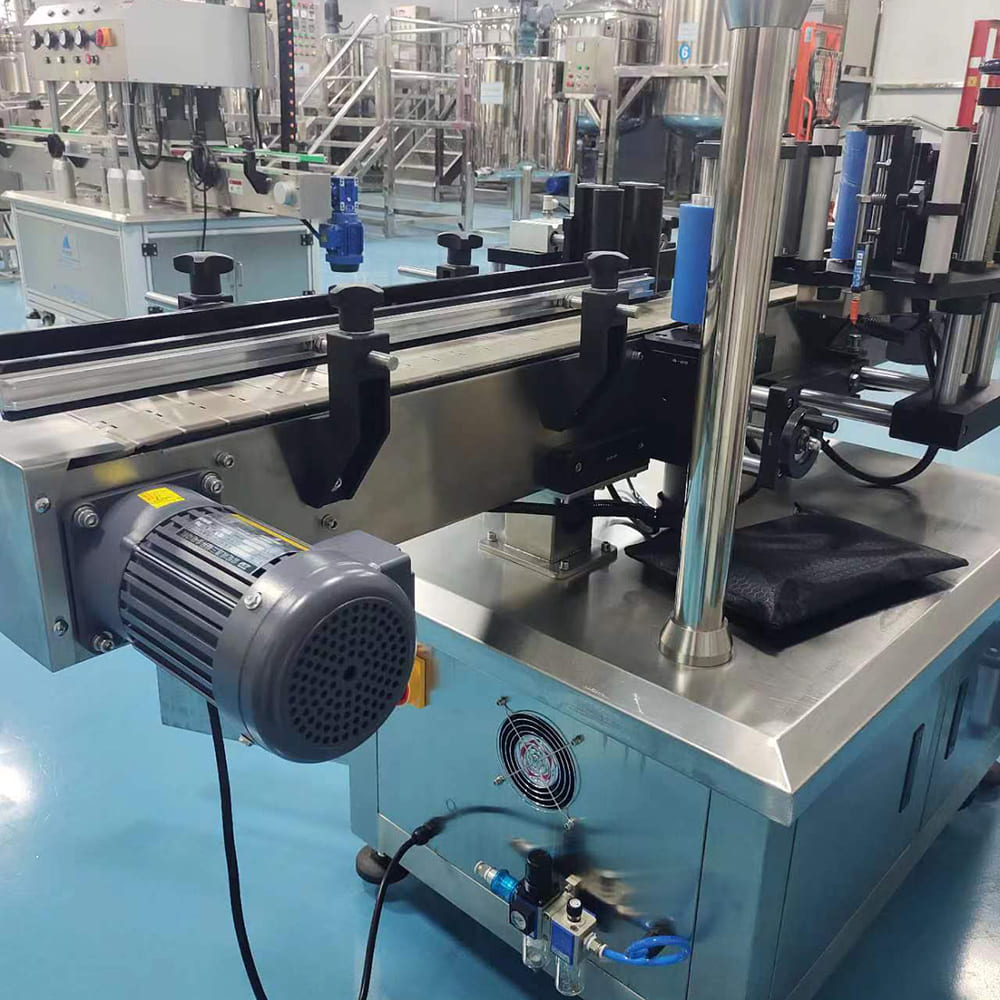

Automatic Round Bottle Labeling Machine for sale Display

What types labels are suitable for this jar labeling machine?

Self-adhesive label, non-adhesive film label, electronic supervision code label, bar code label, paper label, etc. However, the label paper will affect the quality of the labeling machine, so try to choose a better raw material.

Can this label dispenser stick transparent labels?

Yes, if client’s label is transparent, we will add an electric eye for the automatic labeler machine.

Can it print date on the bags, by ink or steel?

Yes, the standard machine is usually added with a ribbon coding machine to print date by ink.

Can I only purchase the parts and install at local, because the big package cost a lot?

As long as client can assemble by himself, can purchase a compete part. This is indeed saves cost. But it is better to buy a set if client are not professional for installation.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery