High Quality Pharmaceutical Liquid Mixers

# Pharmaceutical Liquid Mixers: Precision Mixing Solutions by YUANYANG

High-Performance Mixing for Pharmaceutical Applications

Pharmaceutical liquid mixers are essential for producing uniform, high-quality formulations in drug manufacturing. YUANYANG’s advanced pharmaceutical liquid mixers ensure precise homogenization, emulsification, and blending—critical for vaccines, syrups, and injectables. Our CE-certified machines comply with stringent industry standards, guaranteeing safety and efficiency.

Key Features of YUANYANG’s Pharmaceutical Mixers

Vacuum Homogenizer Mixers for Contamination-Free Blending

Our vacuum homogenizer mixers eliminate air bubbles and prevent oxidation, ensuring superior product stability. Ideal for sensitive pharmaceutical liquids requiring airtight processing.

High Shear Mixers for Rapid Emulsification

YUANYANG’s high shear mixers deliver intense mechanical action, reducing particle size and enhancing dissolution rates—perfect for creams, gels, and suspensions.

Customizable Turnkey Solutions

From mixing to packaging, YUANYANG provides complete production line machines, including storage tanks, filling, and labeling systems. Our one-stop support covers installation, training, and maintenance.

Why Choose YUANYANG?

- CE-Certified Safety: Compliant with EU regulations for industrial equipment.

- 17+ Years of Expertise: Trusted by global pharmaceutical manufacturers since 2008.

- Free Technical Training: Ensure seamless operation with expert guidance.

Upgrade your production with YUANYANG’s pharmaceutical liquid mixers—engineered for precision, durability, and compliance. (#) for a tailored solution today!

*Note: Replace `(#)` with your actual CTA link.*

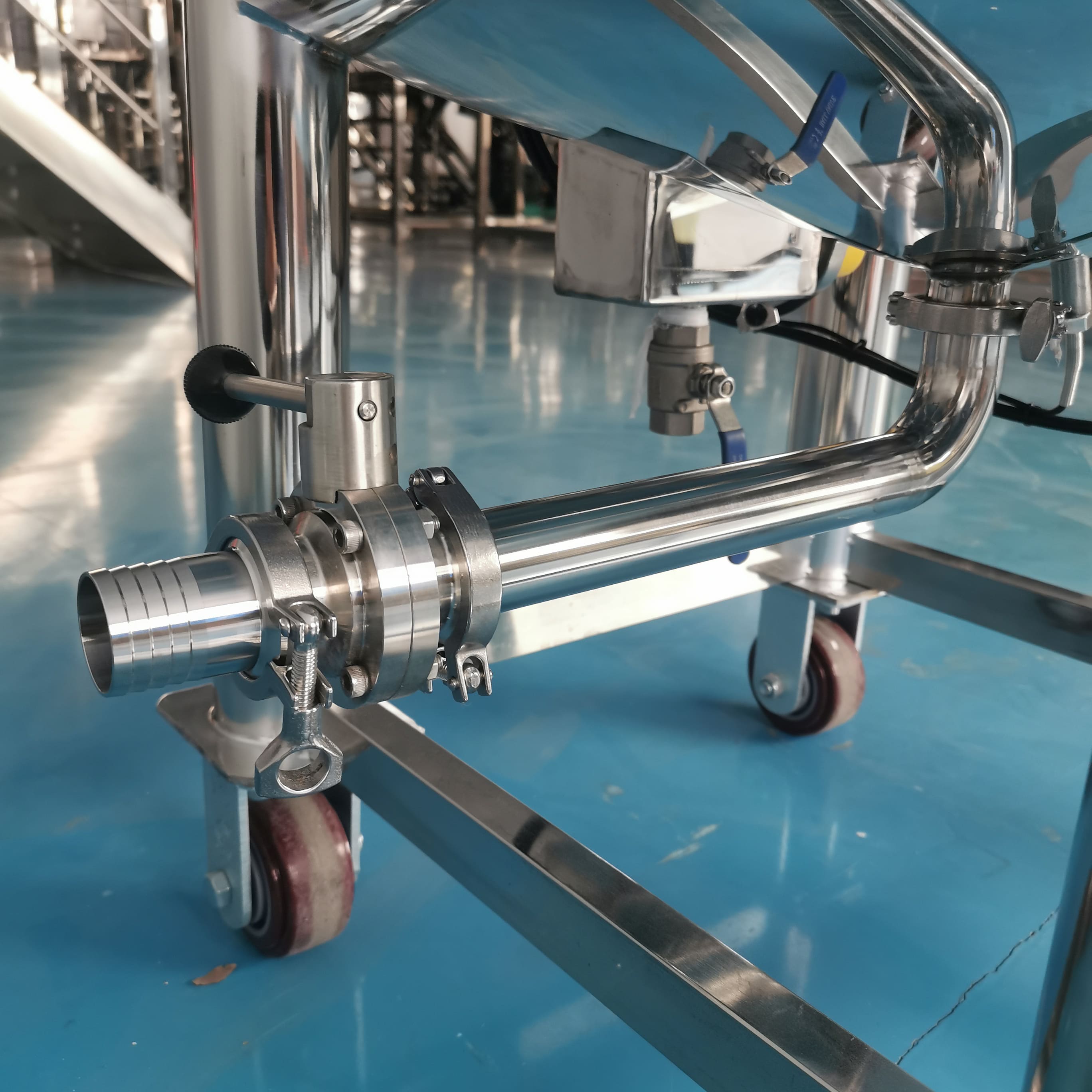

pharmaceutical liquid mixer Display

Can you also help to purchase raw powder for the washing powder mixer?

Sure, we have professional partner who has been engaged in raw powder supply for over 20 years. The price is competitive in the market. If clients need to purchase together, it is recommend to take a container.

Can the upper smaller blade move up or down?

Yes, the extra blades can be flexible fixed higher or lower based on materials depth.

What type of film can the bottle sealer machine work for?

The sealing machine is mainly used for heating and sealing polyolefin (such as polyethylene, polypropylene, etc.) as the inner layer of composite film material sealing.

How long to replace the reverse osmosis membrane and pvc film?

Reverse osmosis membranes are generally recommended to be replaced every year. But it is not a fixed time, the period should be considered according to the actual use environment and operating conditions.

PVC film is recommended to replace every two weeks.

What’s the material of the screw feeding machine?

The feeding machine for powder is maid of stainless steel 304, which meet GMP standards.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery