Automatic Servo Motor Capping Machines | YUANYANG

# Automatic Servo Motor Capping Machines for Sale

Precision Capping Solutions for Your Production Line

YUANYANG offers a range of robust and efficient automatic servo motor capping machines designed to enhance your production line's speed and accuracy. Our machines handle various cap types and sizes, ensuring consistent and reliable capping for a wide array of products. Built for durability and ease of maintenance, these machines minimize downtime and maximize your return on investment.

Superior Technology & Performance

Our automatic servo motor capping machines utilize advanced servo motor technology for precise torque control, ensuring consistent capping pressure across all containers. This prevents damage to caps or bottles and guarantees a tight, leak-proof seal every time. The user-friendly interface simplifies operation and maintenance, making them ideal for diverse production environments.

Streamlined Production & Increased Efficiency

Integrating our automatic capping machines into your production line streamlines your operations and significantly boosts efficiency. Say goodbye to manual capping’s inconsistencies and hello to increased throughput, reduced labor costs, and higher-quality output. Experience a seamless and reliable capping process that keeps your production line running smoothly.

YUANYANG: Your Trusted Partner in Packaging Solutions

As a leading manufacturer of industrial mixing and packaging equipment since 2008, YUANYANG provides comprehensive solutions, including free technical training and complete turnkey services. Our CE certification demonstrates our commitment to safety and quality standards. Choose YUANYANG for reliable, high-performance automatic servo motor capping machines. Contact us today for a consultation and quotation tailored to your specific needs.

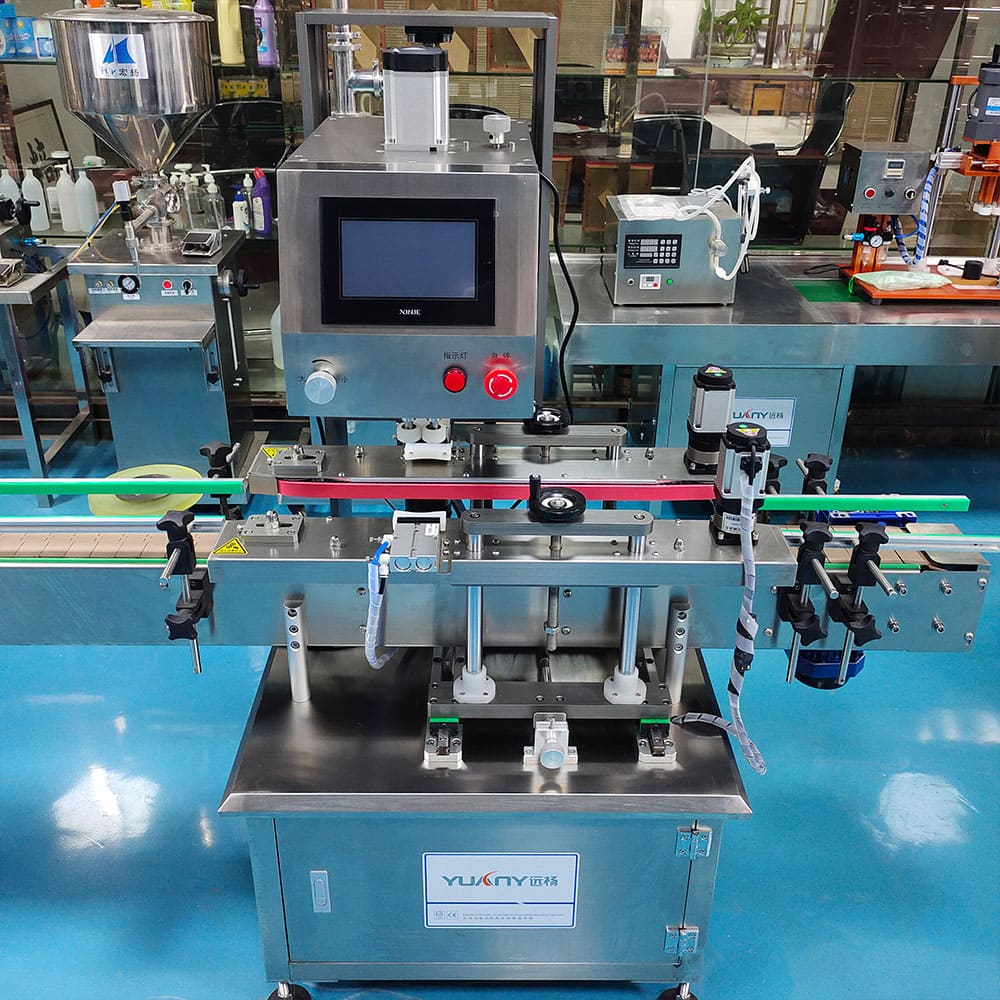

Automatic Servo Motor Capping Machine for sale Display

Can the equipment handle various materials?

Yes, our equipment can handle a wide range of materials, including liquids, powders, pastes, and high-viscosity substances.

Is the plastic bottle capping machine electric drive or pneumatic drive?

This bottle cap closing machine is with both electric drive and pneumatic drive. It requires an air compressor.

Can I change the different paddle by myself?

Generally the paddle can not be replaceable, unless the new paddle to be changed are the same size with the old one.

Why water pot and oil pot are needed?

The combination of water pot and oil pot plays a crucial role for cosmetic production equipment, which ensure the stability of the emulsification process and product quality through pretreatment and precise control each phase materials.

⦁ Pretreatment

The water pot and oil are equipped with heating and dispersing function. Each phase can be dissolved,dispersed,heated before entering into the main emulsifying equipment. The pretreatment improves emulsification efficiency, reduces unnecessary mixing problems, and ensures that the material is in the best condition during emulsification

⦁ Precise control

Each phase is with a separated pot. Through the precise control system of water pot and oil pot, the materials can be added to the emulsion pot according to the preset ratio and speed, to ensure the uniformity and stability of the mixing process. This precise control helps to produce a high quality, consistent product.

What’s the filling range of the screw powder packing machine?

The screw filling machine can fill from 5-1000g. But we need to customize according to specific weight that clients plan to pack. The screw model will be different.

Scan QR Code

Scan QR Code

Facebook

YouTube

LinkedIn

Whatsapp: +8613434139712

Guangzhou Yuanyang Machinery